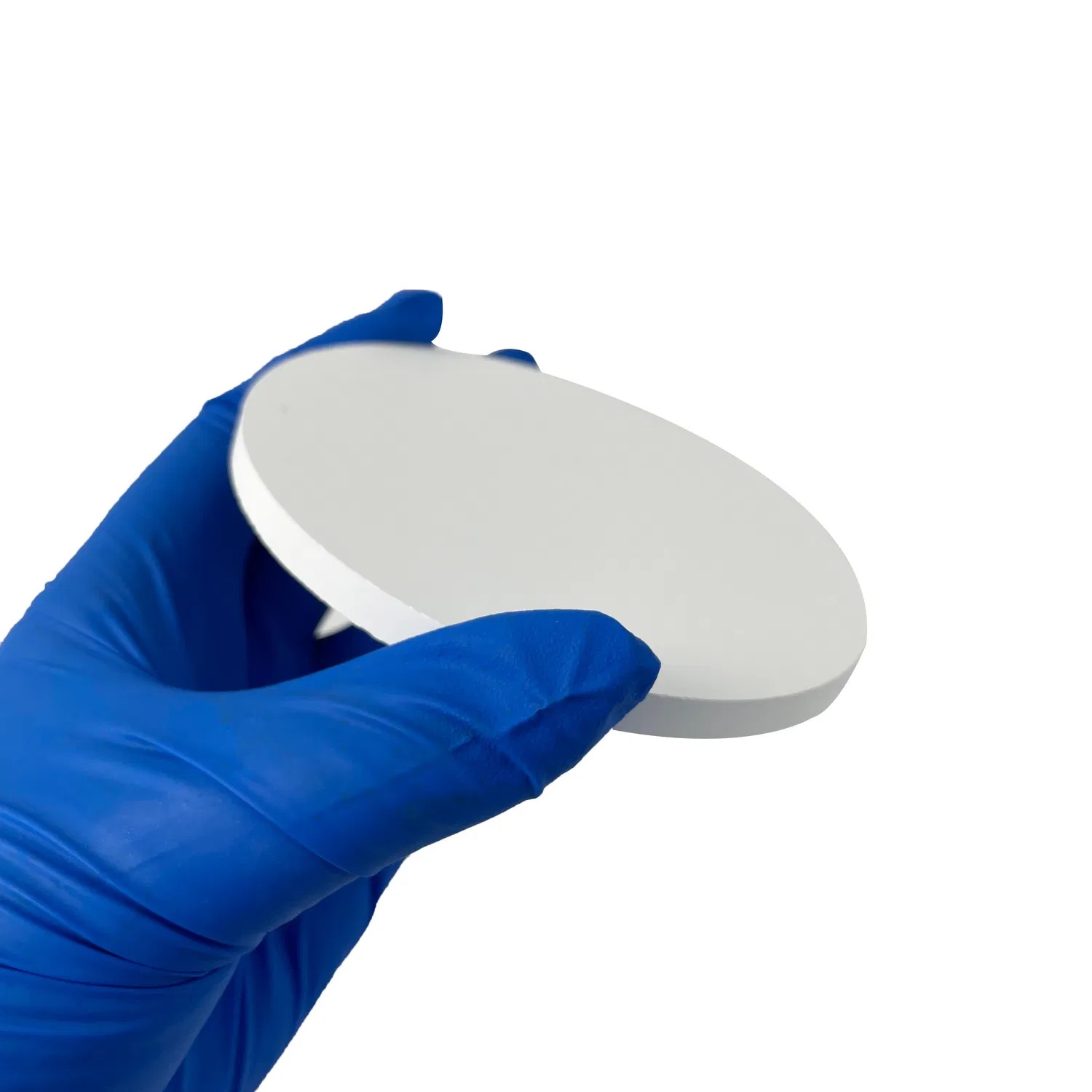

MgF2 (Magnesium Fluoride) Sputtering Target

- Broad Transparency Range: MgF₂ has excellent transmission across UV, visible, and IR spectra, making it an ideal material for high-performance optical coatings.

- Low Refractive Index: The low refractive index of MgF₂ helps reduce light reflection, enabling its use in anti-reflective coatings for various optical applications.

- High Hardness and Durability: Magnesium Fluoride films are known for their hardness and resistance to scratching, making them suitable for protective coatings in high-durability environments.

- Chemical and Environmental Stability: MgF₂ coatings are chemically inert and stable under extreme temperature conditions, enhancing their use in both optical and electronic applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | MgF2 |

| Purity | 99.9% – 99.99999% / 3N 3N5 4N 4N5 5N 5N5 6N 6N5 7N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

MgF₂ (Magnesium Fluoride) sputtering targets are widely used in various optical, electronic, and coating applications. Magnesium Fluoride is highly transparent across a broad range of wavelengths, from deep ultraviolet (UV) to the infrared (IR) spectrum, making it a popular material in the production of anti-reflective (AR) coatings and optical components.

Key Applications:

- Optical Coatings: MgF₂ is commonly used to deposit anti-reflective coatings on lenses, prisms, and other optical components, enhancing light transmission and reducing reflection across UV to IR wavelengths.

- Laser Systems: Due to its broad transparency and low refractive index, MgF₂ sputtering targets are used in laser optics to produce durable coatings for laser windows and mirrors.

- Semiconductor Devices: MgF₂ films serve as protective layers in semiconductor devices, offering chemical resistance and stability under various environmental conditions.

- Thin-Film Deposition: Magnesium Fluoride sputtering targets are used in the deposition of thin films for electronic devices, precision optics, and solar cells, improving the performance and efficiency of these systems.

Features of MgF₂ Sputtering Targets:

- Broad Transparency Range: MgF₂ has excellent transmission across UV, visible, and IR spectra, making it an ideal material for high-performance optical coatings.

- Low Refractive Index: The low refractive index of MgF₂ helps reduce light reflection, enabling its use in anti-reflective coatings for various optical applications.

- High Hardness and Durability: Magnesium Fluoride films are known for their hardness and resistance to scratching, making them suitable for protective coatings in high-durability environments.

- Chemical and Environmental Stability: MgF₂ coatings are chemically inert and stable under extreme temperature conditions, enhancing their use in both optical and electronic applications.

Customization Options:

- Target Sizes and Shapes: MgF₂ sputtering targets are available in different sizes, shapes, and thicknesses to suit a variety of deposition systems and application requirements.

- High Purity: High-purity MgF₂ targets are essential for the production of high-quality thin films, ensuring optimal performance in precision optics and semiconductor devices.

- Bonding Services: To enhance thermal performance and improve target longevity during the sputtering process, bonding services for MgF₂ targets are available.

MgF₂ (Magnesium Fluoride) sputtering targets from Tinsan Materials are ideal for anti-reflective coatings, optical components, and laser systems. Offering broad transparency from UV to IR, low refractive index, and excellent durability. Available in custom sizes and high-purity options for precision thin-film applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.