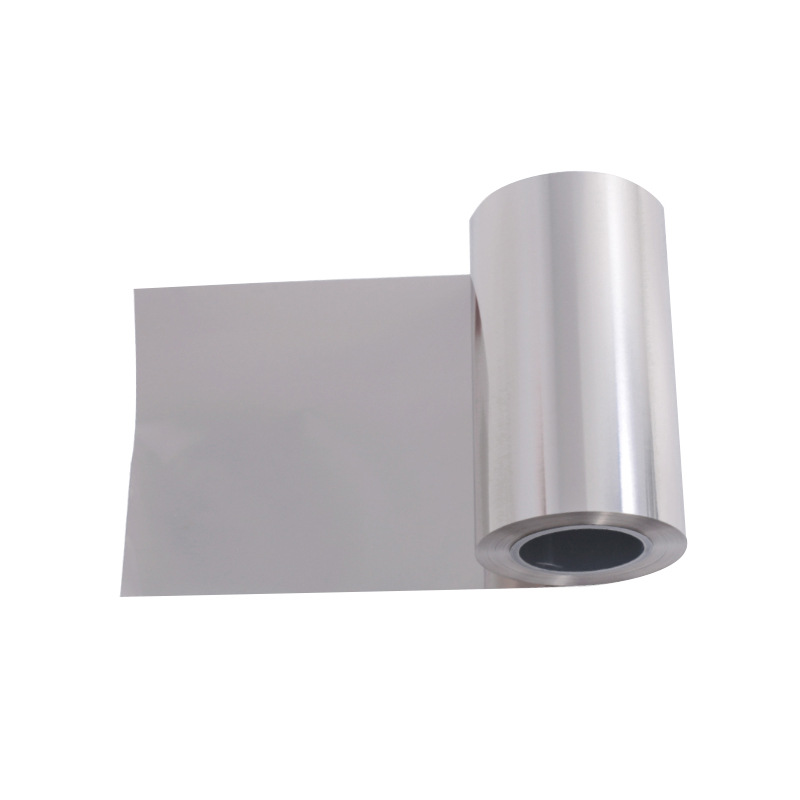

Mo Molybdenum Foil

- High Melting Point: With a melting point of 2623°C, molybdenum foil can withstand extreme temperatures.

- Thermal and Electrical Conductivity: Molybdenum exhibits excellent thermal and electrical conductivity, essential for heat dissipation and electrical components.

- High Purity: Available in ultra-high purity grades, ensuring consistent performance in sensitive applications.

- Corrosion Resistance: Molybdenum is highly resistant to oxidation and corrosion, even in extreme environments.

- Strength and Stability: Molybdenum foil maintains mechanical strength and dimensional stability at high temperatures.

- Malleability and Workability: Despite its robustness, molybdenum foil is malleable and can be fabricated into complex shapes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Molybdenum foil is a versatile material with exceptional thermal and mechanical properties, making it indispensable in various industrial and scientific applications. With a high melting point, excellent thermal conductivity, and resistance to corrosion, molybdenum foil is widely used in electronics, aerospace, and high-temperature environments. Tinsan Materials offers premium-quality molybdenum foil tailored to diverse industry needs.

Properties of Molybdenum Foil

- High Melting Point: With a melting point of 2623°C, molybdenum foil can withstand extreme temperatures.

- Thermal and Electrical Conductivity: Molybdenum exhibits excellent thermal and electrical conductivity, essential for heat dissipation and electrical components.

- High Purity: Available in ultra-high purity grades, ensuring consistent performance in sensitive applications.

- Corrosion Resistance: Molybdenum is highly resistant to oxidation and corrosion, even in extreme environments.

- Strength and Stability: Molybdenum foil maintains mechanical strength and dimensional stability at high temperatures.

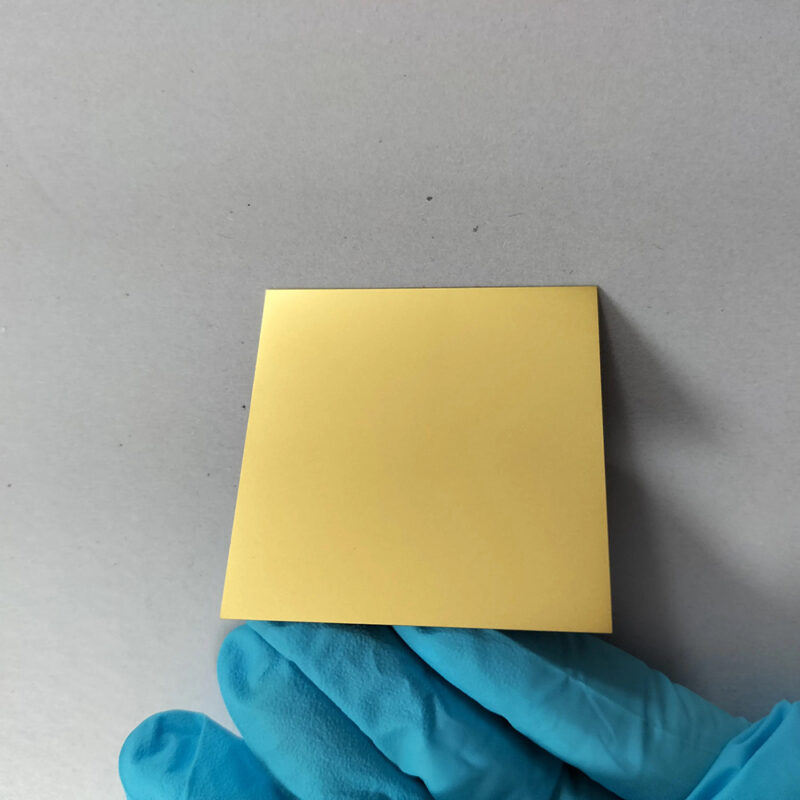

- Malleability and Workability: Despite its robustness, molybdenum foil is malleable and can be fabricated into complex shapes.

Advantages of Molybdenum Foil

- High-Temperature Performance: Molybdenum foil is ideal for applications requiring prolonged exposure to heat.

- Long-Lasting Durability: Resistant to wear, oxidation, and chemical attack, ensuring extended operational life.

- Efficient Heat Dissipation: Excellent thermal conductivity enhances performance in high-temperature and electronic applications.

- Precision Manufacturing: Molybdenum foil can be processed into ultra-thin sheets, meeting stringent dimensional and purity requirements.

- Versatility: Suitable for use across a wide range of industries, including aerospace, electronics, and energy.

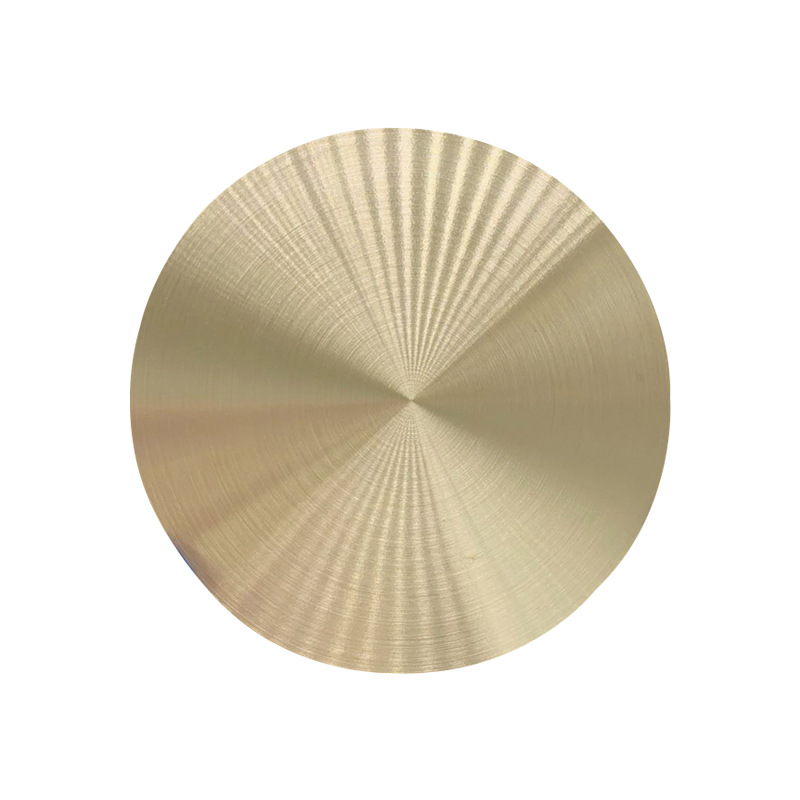

Applications of Molybdenum Foil

- Electronics and Semiconductors: Used in transistors, diodes, and thin-film solar cells due to its electrical conductivity and thermal stability.

- Aerospace: Molybdenum foil is utilized in heat shields, furnace components, and propulsion systems.

- Lighting and Filaments: Ideal for manufacturing lamp components and heating elements due to its resistance to heat and oxidation.

- Nuclear Industry: Molybdenum’s ability to withstand radiation makes it valuable in nuclear reactors and shielding.

- Medical Equipment: Used in X-ray equipment and medical devices due to its strength and biocompatibility.

- Thermal Management: Essential in heat sinks and heat spreaders for electronic devices and high-power applications.

- Advanced Research: Utilized in scientific experiments, including high-temperature and vacuum environments.

At Tinsan Materials, we manufacture molybdenum foil in various thicknesses and widths to meet specific industrial requirements. Our products are precision-engineered to ensure superior quality and performance, even in the most challenging environments.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.