Mo Molybdenum Wire

- High-Temperature Performance: Its exceptional performance in extreme heat conditions makes molybdenum wire indispensable in industries such as aerospace and electronics.

- Versatility: Molybdenum wire is available in various diameters and lengths, customizable for different industrial needs.

- Durability and Longevity: With its ability to resist wear, oxidation, and deformation, molybdenum wire delivers long-lasting performance.

- Precision Fabrication: It can be produced with tight tolerances and high precision, ensuring reliability in demanding applications.

- Eco-Friendly Material: Molybdenum is a recyclable material, making it an environmentally sustainable choice.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

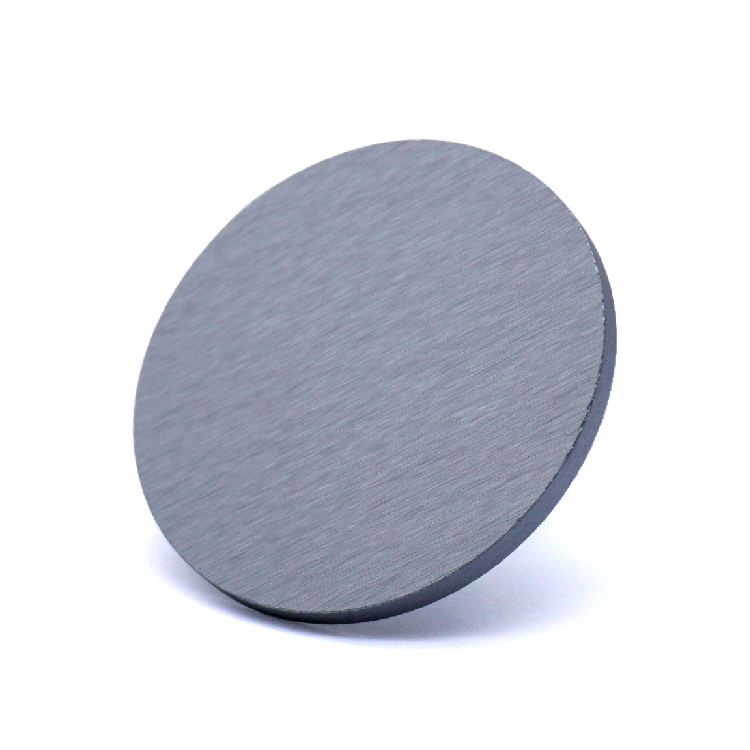

Molybdenum wire is a versatile and high-performance material known for its exceptional mechanical, electrical, and thermal properties. It is widely used in a variety of industries, including electronics, aerospace, medical, and more, due to its unique characteristics. Below is a detailed overview of the properties, advantages, and applications of molybdenum wire.

Key Properties of Molybdenum Wire

- High Melting Point: Molybdenum has an extremely high melting point of 2,623°C (4,753°F), making it ideal for high-temperature environments.

- Excellent Strength and Hardness: It retains its mechanical strength and hardness at elevated temperatures, ensuring durability under extreme conditions.

- High Thermal Conductivity: Molybdenum wire efficiently dissipates heat, making it suitable for thermal applications.

- Low Thermal Expansion: Its low coefficient of thermal expansion minimizes dimensional changes with temperature fluctuations, ensuring stability in precision applications.

- Superior Electrical Conductivity: Molybdenum wire offers reliable electrical conductivity, ideal for electrical discharge machining (EDM) and other electronic applications.

- Corrosion and Oxidation Resistance: It exhibits excellent resistance to corrosion and oxidation, especially in inert or vacuum environments.

- Chemical Stability: Molybdenum is highly resistant to chemical reactions, making it suitable for chemically aggressive environments.

Advantages of Molybdenum Wire

- High-Temperature Performance: Its exceptional performance in extreme heat conditions makes molybdenum wire indispensable in industries such as aerospace and electronics.

- Versatility: Molybdenum wire is available in various diameters and lengths, customizable for different industrial needs.

- Durability and Longevity: With its ability to resist wear, oxidation, and deformation, molybdenum wire delivers long-lasting performance.

- Precision Fabrication: It can be produced with tight tolerances and high precision, ensuring reliability in demanding applications.

- Eco-Friendly Material: Molybdenum is a recyclable material, making it an environmentally sustainable choice.

Applications of Molybdenum Wire

- Electronics: Used as heating elements, electrodes, and filaments in vacuum tubes, halogen lamps, and electron beam sources due to its high conductivity and thermal stability.

- Aerospace: Molybdenum wire is used in high-temperature components such as rocket engine parts and thermal shielding in spacecraft.

- Electrical Discharge Machining (EDM): Its superior conductivity and precision make it ideal for EDM applications in tool and die manufacturing.

- Medical Devices: Used in X-ray tubes, diagnostic equipment, and surgical tools due to its excellent strength, stability, and biocompatibility.

- Metallurgy: Utilized in the production of molybdenum alloys and for reinforcing other metals to improve their properties.

- Solar and Semiconductor Industries: Molybdenum wire is used for interconnects and thin-film deposition in solar cells and semiconductors.

- High-Temperature Furnaces: Employed as heating elements and support structures in high-temperature vacuum furnaces.

- Chemical Processing: Used in aggressive chemical environments due to its resistance to corrosion and chemical stability.

Molybdenum wire is a critical material for applications demanding high-temperature resilience, strength, and precision. Its unique properties, including excellent thermal and electrical conductivity, make it suitable for a broad range of industrial and scientific applications.

At Tinsan Materials, we provide high-quality molybdenum wire tailored to meet the exact needs of our clients. Our products are manufactured with stringent quality controls to ensure consistent performance and durability.

Contact us today to learn how our molybdenum wire solutions can benefit your projects.