MoB2 (Molybdenum Diboride) Sputtering Targets

- High Hardness: Provides robust protective coatings for enhanced durability.

- Thermal and Chemical Stability: Ensures excellent performance in harsh environments.

- Electrical Conductivity: Suitable for electronic applications requiring conductive thin films.

- Customizable Options: Available in various dimensions and configurations for specific needs.

- Consistent Quality: Manufactured to deliver uniform deposition rates and film properties.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Diboride (MoB₂) |

| Purity | 99.5% – 99.999% / 2N5 3N 3N5 4N 4N5 5N |

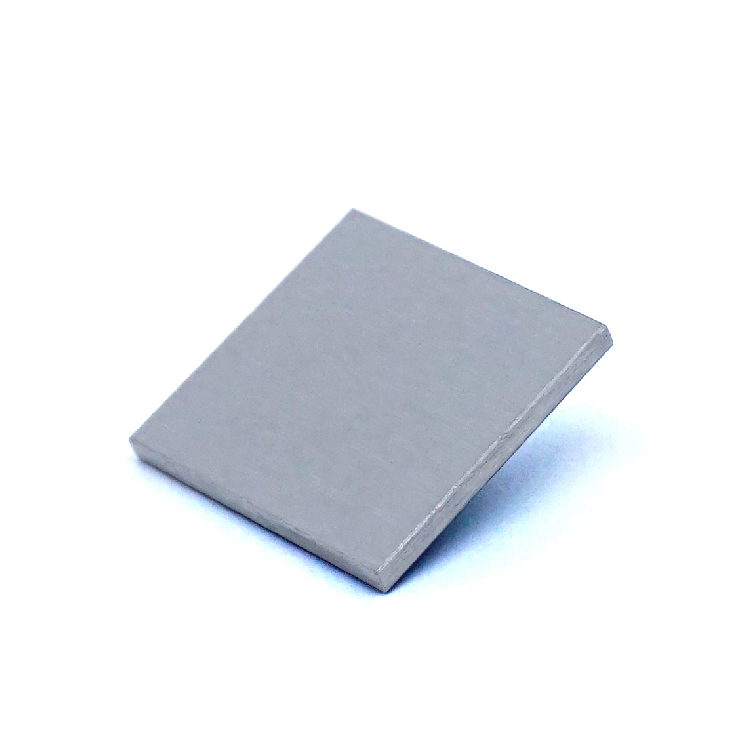

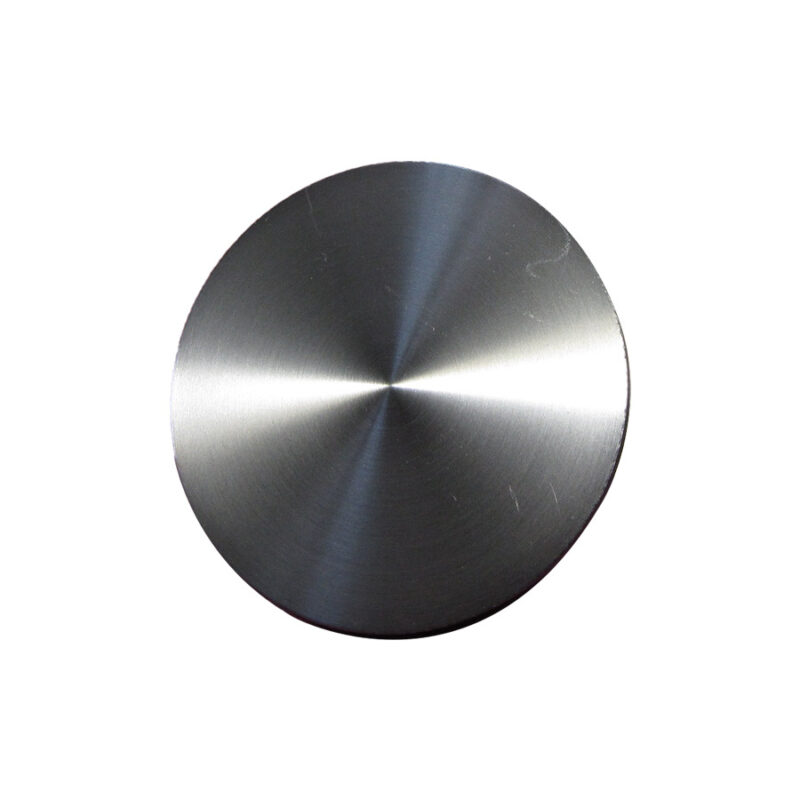

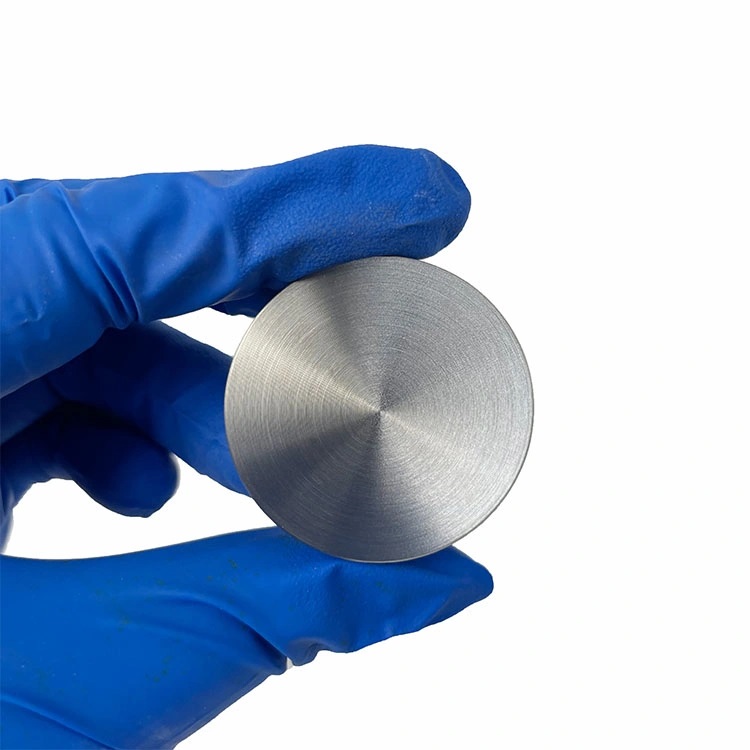

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum Diboride (MoB₂) sputtering targets are advanced ceramic materials designed for thin-film deposition in applications demanding high hardness, corrosion resistance, and thermal stability. With excellent mechanical and electrical properties, MoB₂ is commonly used in protective coatings, microelectronics, and other high-performance technologies.

Key Applications

- Hard Protective Coatings: Ideal for wear-resistant and corrosion-resistant surfaces.

- Microelectronics: Used in semiconductors and thin-film resistors.

- Thermal Barrier Coatings: Protects components in high-temperature environments.

- Tribological Films: Enhances friction-reducing coatings in mechanical systems.

- Aerospace and Defense: Suitable for applications requiring durability and resistance to extreme conditions.

Features and Benefits

- High Hardness: Provides robust protective coatings for enhanced durability.

- Thermal and Chemical Stability: Ensures excellent performance in harsh environments.

- Electrical Conductivity: Suitable for electronic applications requiring conductive thin films.

- Customizable Options: Available in various dimensions and configurations for specific needs.

- Consistent Quality: Manufactured to deliver uniform deposition rates and film properties.

Specifications

- Purity: ≥ 99.5% for high-performance applications.

- Density: Optimized for efficient sputtering and material utilization.

- Dimensions: Custom sizes and shapes available to match sputtering equipment.

- Surface Finish: Smooth, polished surface for uniform thin-film deposition.

- Forms: Discs, rectangular plates, and other geometries as required.

Customization Options

- Shape and Size Adaptability: Tailored to meet specific deposition system requirements.

- Bonding Services: Backing plate integration for improved thermal management.

- Special Coating Options: Enhanced target longevity and performance.

- Packaging: Secure packaging for safe transport and storage.

Partner with us for premium-quality Molybdenum Diboride (MoB₂) sputtering targets tailored to your thin-film deposition needs. Reach out to explore custom solutions, expert support, and rapid delivery services.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.