MoCu (Molybdenum Copper) Alloy Target

- High Thermal Conductivity: Copper’s excellent thermal conductivity ensures effective heat dissipation in thin-film coatings, crucial for applications in electronics and thermal management systems.

- Mechanical Strength: Molybdenum contributes strength and rigidity to the MoCu alloy, ensuring mechanical stability in high-temperature and high-stress applications.

- Corrosion Resistance: The MoCu alloy provides good resistance to corrosion, making it suitable for use in environments where materials are exposed to moisture, chemicals, or harsh conditions.

- Low Thermal Expansion: The alloy’s combination of molybdenum and copper results in low thermal expansion, reducing the risk of film cracking or damage under thermal stress.

- Customizable Composition: The ratio of molybdenum to copper can be tailored to optimize the thermal, electrical, and mechanical properties to meet specific application requirements.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Cuprum |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

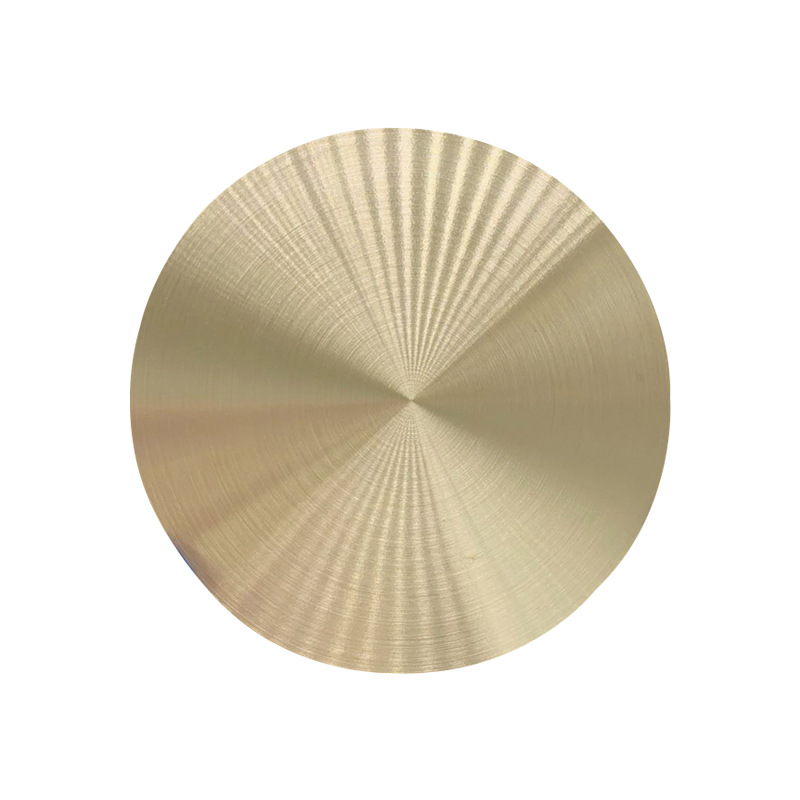

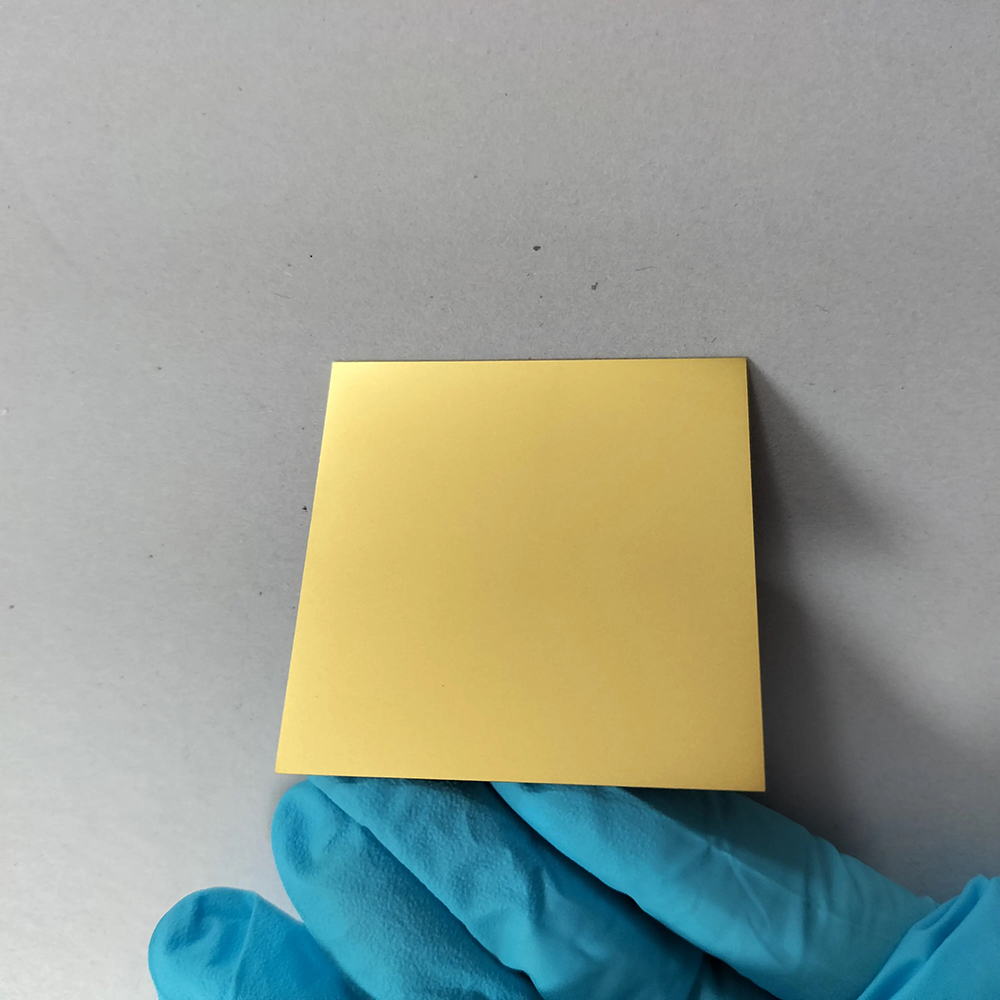

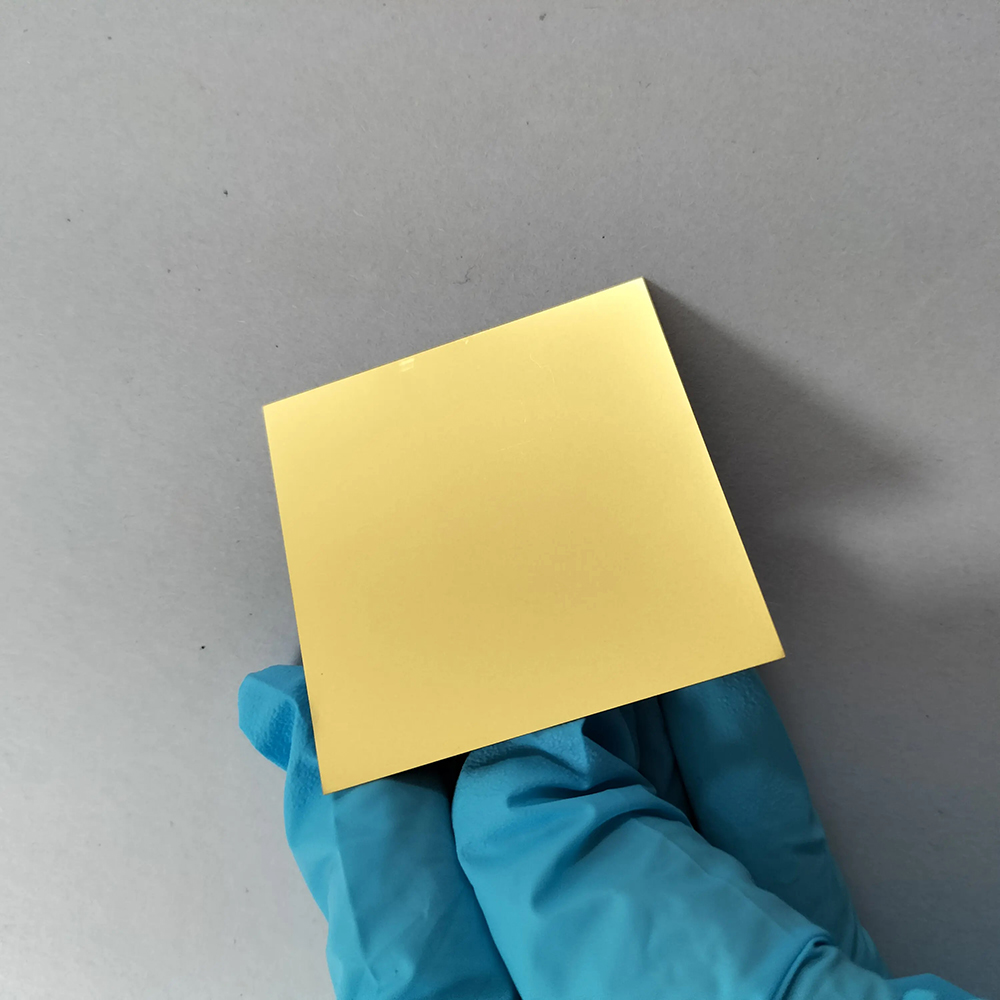

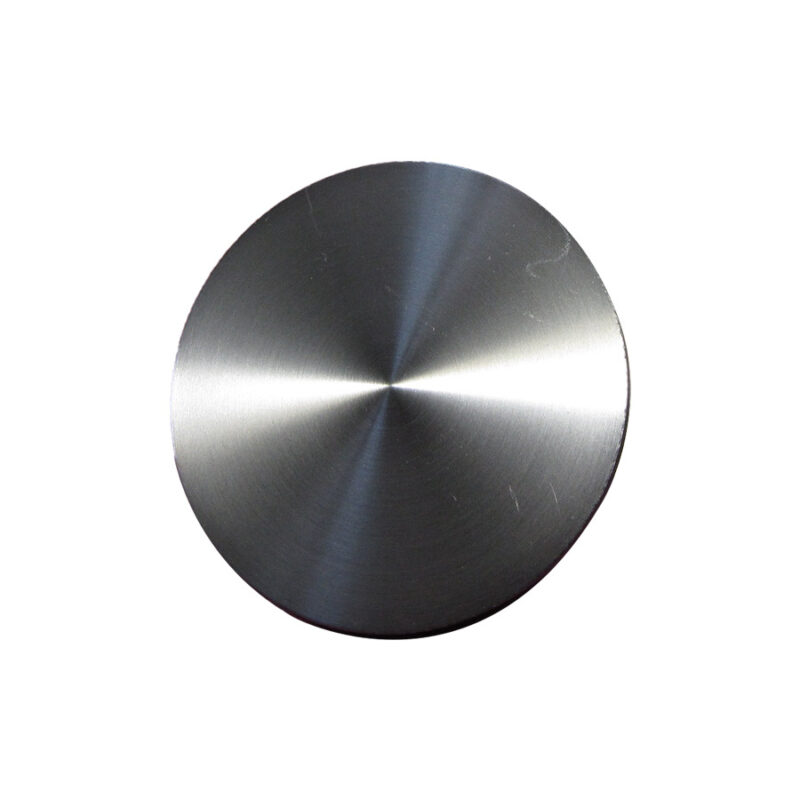

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum-Copper (MoCu) alloy sputtering targets combine the high thermal and electrical conductivity of copper with the strength, thermal stability, and corrosion resistance of molybdenum. These targets are commonly used in thin-film deposition for applications requiring excellent thermal management, wear resistance, and structural integrity in high-performance environments.

Key Applications:

- Thermal Management in Electronics: MoCu alloy thin films are used in electronic components and devices that require efficient heat dissipation, such as integrated circuits (ICs), power modules, and semiconductor devices, due to their excellent thermal conductivity.

- Electronics and Microelectronics: The combination of conductivity and mechanical strength makes MoCu thin films suitable for conductive layers in electronics, particularly in applications where high thermal stability and electrical conductivity are crucial.

- Aerospace and Defense: MoCu coatings are used in high-temperature applications in aerospace and defense industries, where materials must withstand extreme thermal conditions and mechanical stresses.

- Vacuum and Plasma Systems: Due to their low outgassing properties and resistance to corrosion, MoCu alloy sputtering targets are used in vacuum and plasma deposition systems for creating protective and conductive coatings.

- Heat Sinks and Cooling Systems: The high thermal conductivity of copper combined with molybdenum’s structural stability makes MoCu thin films ideal for heat sinks, cooling devices, and components that need to manage large amounts of heat efficiently.

Features of MoCu Alloy Sputtering Targets:

- High Thermal Conductivity: Copper’s excellent thermal conductivity ensures effective heat dissipation in thin-film coatings, crucial for applications in electronics and thermal management systems.

- Mechanical Strength: Molybdenum contributes strength and rigidity to the MoCu alloy, ensuring mechanical stability in high-temperature and high-stress applications.

- Corrosion Resistance: The MoCu alloy provides good resistance to corrosion, making it suitable for use in environments where materials are exposed to moisture, chemicals, or harsh conditions.

- Low Thermal Expansion: The alloy’s combination of molybdenum and copper results in low thermal expansion, reducing the risk of film cracking or damage under thermal stress.

- Customizable Composition: The ratio of molybdenum to copper can be tailored to optimize the thermal, electrical, and mechanical properties to meet specific application requirements.

Customization Options:

- Dimensions: MoCu sputtering targets are available in various sizes and shapes, such as discs, plates, and custom geometries, to fit different deposition systems and requirements.

- Purity Levels: High-purity MoCu alloy sputtering targets (up to 99.99%) are available for use in high-precision electronic, aerospace, and thermal management applications.

- Composition Adjustments: The molybdenum-to-copper ratio can be customized to achieve the desired thermal, mechanical, or electrical properties for specific thin-film applications.

MoCu alloy sputtering targets from Tinsan Materials provide high thermal conductivity, mechanical strength, and corrosion resistance for applications in electronics, aerospace, and thermal management. Custom sizes and compositions available for optimized thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.