MoLa (Molybdenum Lanthanum) Alloy Target

- High Thermal Stability: The MoLa alloy has excellent resistance to deformation and oxidation at high temperatures, ensuring reliability in demanding thermal environments.

- Enhanced Ductility: The addition of lanthanum oxide improves the ductility of molybdenum, making the alloy easier to process and form into thin films without compromising its strength.

- Oxidation Resistance: MoLa exhibits outstanding resistance to oxidation, especially at elevated temperatures, providing long-term stability and durability.

- Improved Machinability: The lanthanum content enhances the machinability of molybdenum, allowing for more precise fabrication of sputtering targets and thin-film coatings.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Lanthanum |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

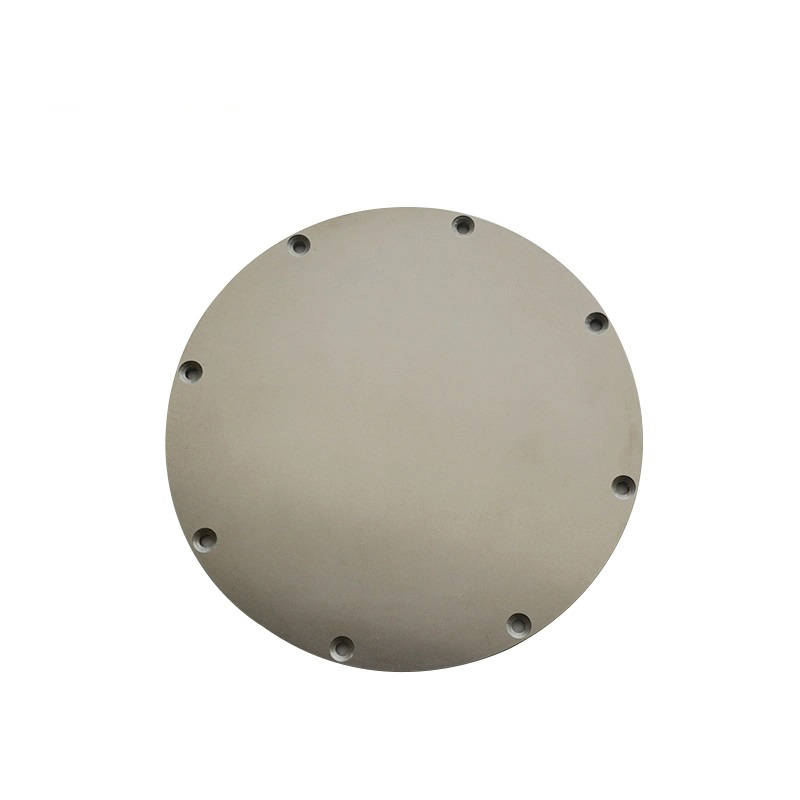

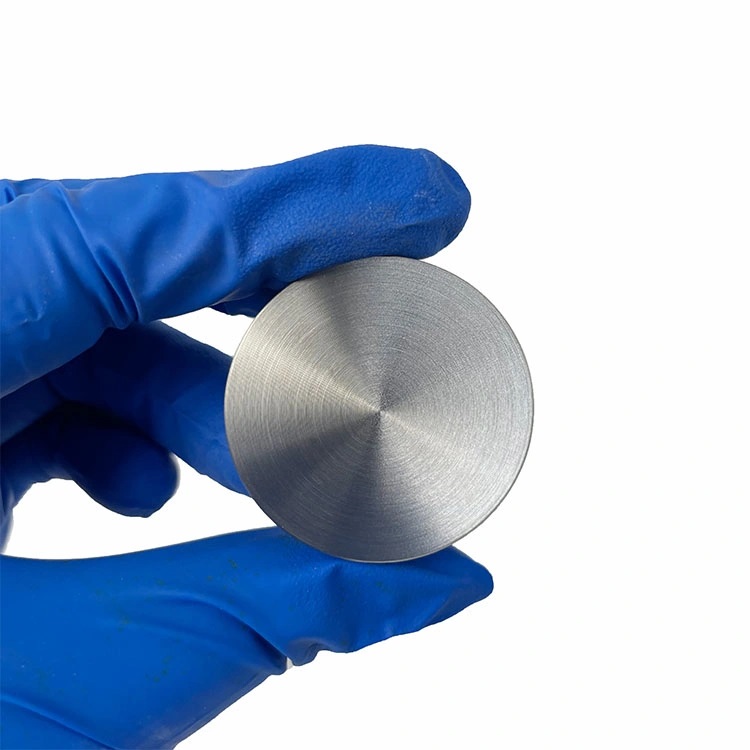

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum-Lanthanum (MoLa) alloy sputtering targets are well-regarded for their high temperature resistance, mechanical strength, and excellent thermal conductivity. The addition of lanthanum oxide (La₂O₃) enhances the ductility and machinability of molybdenum, making MoLa alloys an ideal material for applications requiring structural stability under extreme heat and mechanical stress.

Key Applications:

- Semiconductor Industry: MoLa alloy thin films are used in semiconductor manufacturing for components that must withstand high temperatures and offer stable electrical performance.

- Aerospace and Defense: Due to its thermal stability and strength, MoLa is employed in aerospace applications, such as in rocket nozzles, heat shields, and components exposed to high temperatures and mechanical stress.

- High-Temperature Furnaces: MoLa alloy is used in heating elements and structural components of high-temperature furnaces due to its resistance to thermal deformation and oxidation at elevated temperatures.

- Lighting and Display Technology: MoLa sputtering targets are applied in the production of high-performance coatings for lighting equipment and displays, providing durability and high thermal conductivity.

- Power Generation: MoLa coatings are used in the power generation industry, particularly in components that require superior heat resistance and long-lasting performance under harsh conditions.

Features of MoLa Alloy Sputtering Targets:

- High Thermal Stability: The MoLa alloy has excellent resistance to deformation and oxidation at high temperatures, ensuring reliability in demanding thermal environments.

- Enhanced Ductility: The addition of lanthanum oxide improves the ductility of molybdenum, making the alloy easier to process and form into thin films without compromising its strength.

- Oxidation Resistance: MoLa exhibits outstanding resistance to oxidation, especially at elevated temperatures, providing long-term stability and durability.

- Improved Machinability: The lanthanum content enhances the machinability of molybdenum, allowing for more precise fabrication of sputtering targets and thin-film coatings.

Customization Options:

- Dimensions: MoLa sputtering targets can be manufactured in various sizes and shapes, including discs, plates, and custom geometries, to suit specific deposition systems.

- Purity Levels: High-purity MoLa alloy sputtering targets (up to 99.99%) are available for applications requiring precise material performance, such as in semiconductor and aerospace industries.

- Lanthanum Content: The amount of lanthanum oxide can be adjusted in the alloy to fine-tune properties like ductility and thermal stability, optimizing the target for specific applications.

MoLa alloy sputtering targets from Tinsan Materials offer high thermal stability, oxidation resistance, and enhanced machinability for semiconductor, aerospace, and high-temperature furnace applications. Custom sizes and compositions available for optimized thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.