Molybdenum Mo Evaporation Boats

- High Temperature Resistance: Molybdenum boats perform exceptionally well at high temperatures, ensuring stable evaporation even in demanding applications.

- Long Service Life: The durability and thermal stability of molybdenum result in a longer service life, reducing the need for frequent replacements.

- Customization: Molybdenum boats can be customized in terms of shape, size, and material composition to meet specific application requirements.

- Cost-Effective: Compared to other high-performance materials, molybdenum boats offer a balance of affordability and high performance, making them a cost-effective choice for many applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

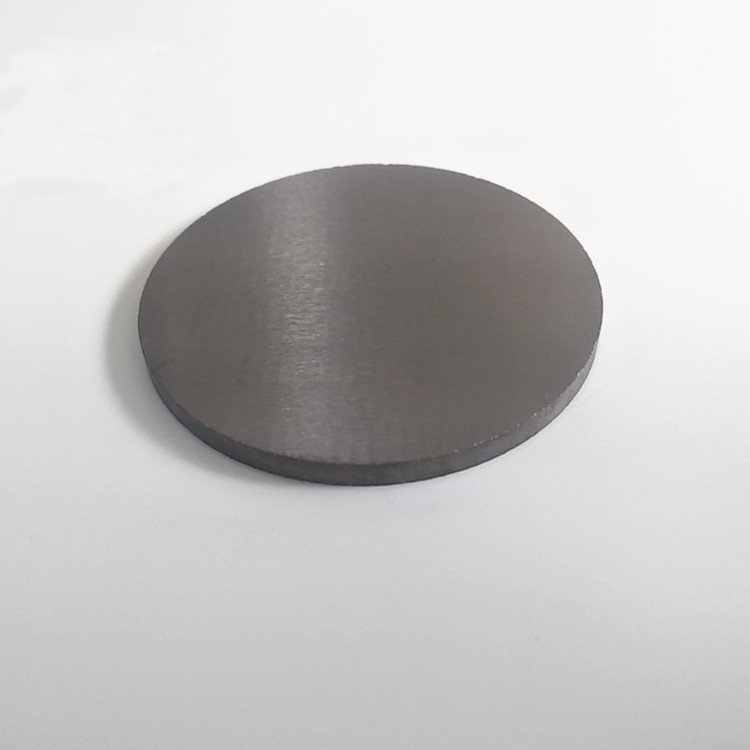

Molybdenum boats are critical components in vacuum evaporation and thin-film deposition processes. Known for their excellent high-temperature stability and reliability, these boats are used in a variety of applications, particularly in the semiconductor, electronics, and material coating industries.

Key Properties of Molybdenum Boats

- High Melting Point: Molybdenum has a high melting point of 2623°C (4753°F), making it ideal for high-temperature evaporation processes.

- Good Thermal Conductivity: Efficient heat transfer properties ensure uniform evaporation, preventing material degradation and ensuring consistent thin-film deposition.

- Mechanical Strength: Molybdenum boats have excellent mechanical strength, which provides durability even under high stress during thermal evaporation cycles.

- Corrosion Resistance: Molybdenum is resistant to many corrosive substances, including certain acids, which makes it suitable for use in harsh environments.

- Low Vapor Pressure: Molybdenum boats have a low vapor pressure at high temperatures, minimizing contamination during the deposition process.

Advantages of Molybdenum Boats

- High Temperature Resistance: Molybdenum boats perform exceptionally well at high temperatures, ensuring stable evaporation even in demanding applications.

- Long Service Life: The durability and thermal stability of molybdenum result in a longer service life, reducing the need for frequent replacements.

- Customization: Molybdenum boats can be customized in terms of shape, size, and material composition to meet specific application requirements.

- Cost-Effective: Compared to other high-performance materials, molybdenum boats offer a balance of affordability and high performance, making them a cost-effective choice for many applications.

Applications of Molybdenum Boats

- Thin-Film Deposition: Widely used in vacuum evaporation processes for depositing thin films of metals, semiconductors, and other materials onto substrates in the semiconductor industry.

- Metallization of Electronics: Molybdenum boats are essential for the metallization process in electronics, particularly in the fabrication of integrated circuits and microelectronic devices.

- Solar Panel Manufacturing: Used in the deposition of metal layers in the production of solar cells and photovoltaic panels.

- Optical Coatings: Molybdenum boats are used in the deposition of thin metal films for optical coatings, such as anti-reflection coatings or mirrors.

- Vacuum Coating Systems: Integral to various vacuum coating processes in industries like automotive, aerospace, and decorative coatings.

Custom Manufacturing Solutions

At Tinsan Materials, we offer customized molybdenum boats tailored to your specific needs. Our customization options include:

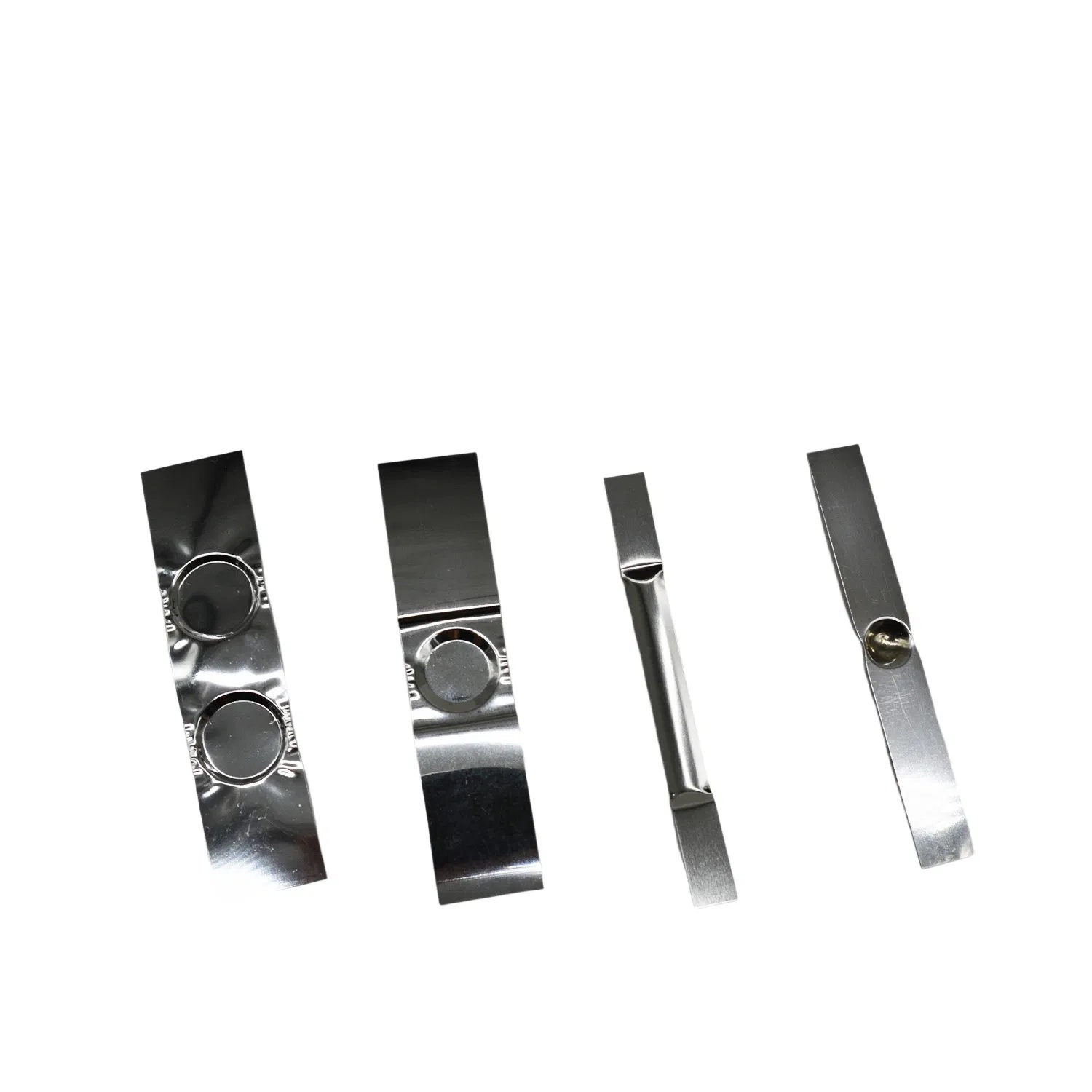

- Shape and Size: Boats can be produced in various shapes (e.g., flat, crucible-style) and sizes for different evaporation systems.

- Material Purity: High-purity molybdenum is used to ensure minimal contamination during the deposition process.

- Special Designs: We can create multi-slot boats or other designs to suit specialized evaporation processes and material handling.

Why Choose Tinsan Materials?

- Expert Manufacturing: With years of experience in the thin-film deposition industry, Tinsan Materials produces high-quality molybdenum boats that are engineered for precision and reliability.

- Customization and Flexibility: We offer flexible solutions for custom designs, ensuring our products meet your specific process requirements.

- Quality Assurance: Every molybdenum boat undergoes rigorous testing for quality, durability, and dimensional accuracy to meet industry standards.

- Competitive Pricing: Our molybdenum boats combine high performance with competitive pricing, providing great value for your investment.

Molybdenum boats from Tinsan Materials are the ideal choice for high-performance thin-film deposition applications. With excellent thermal conductivity, high-temperature resistance, and corrosion resistance, these boats ensure precision and efficiency in your evaporation processes. Contact us for tailored molybdenum boats that meet your unique requirements.