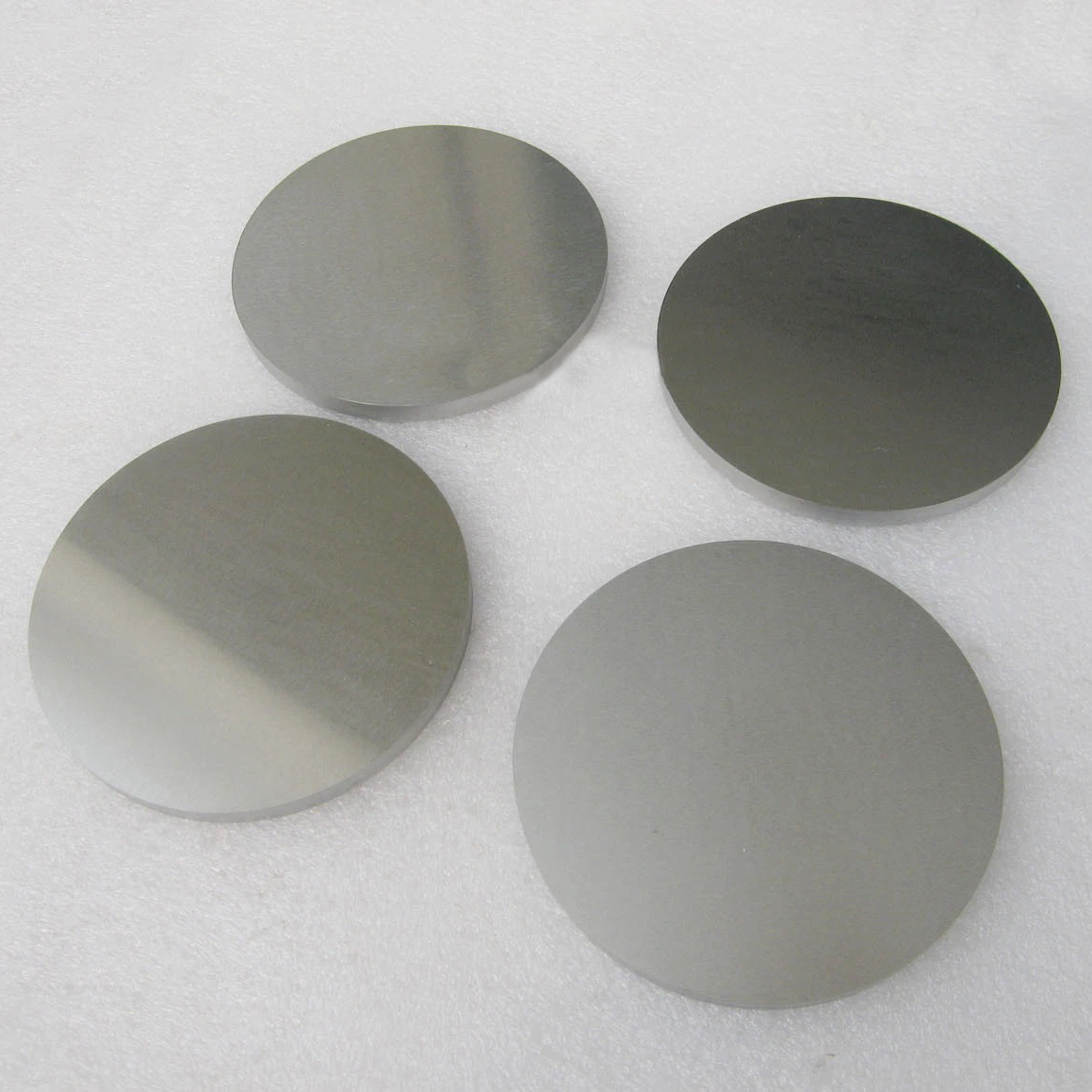

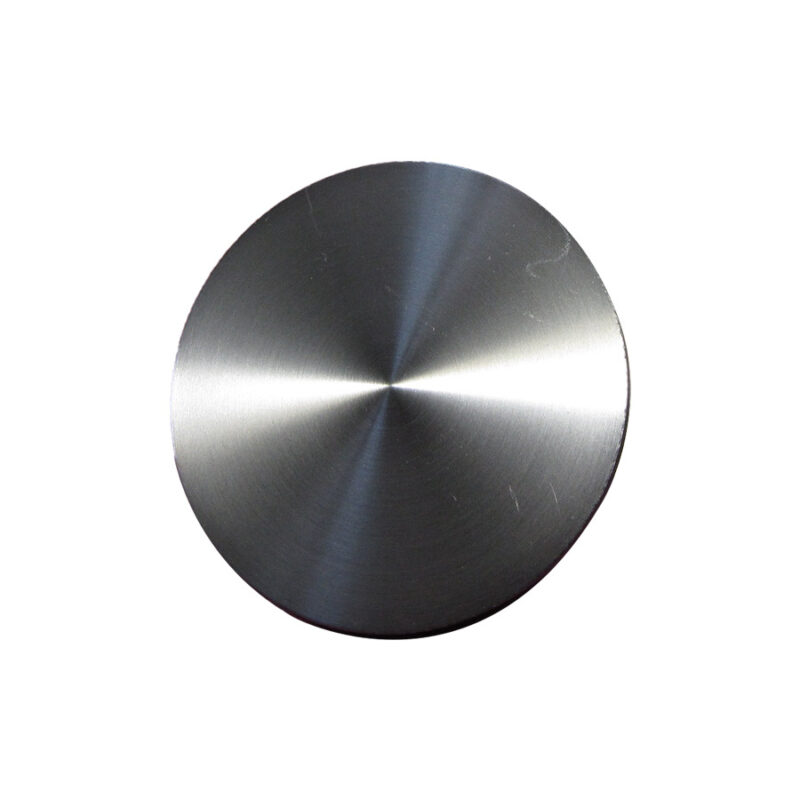

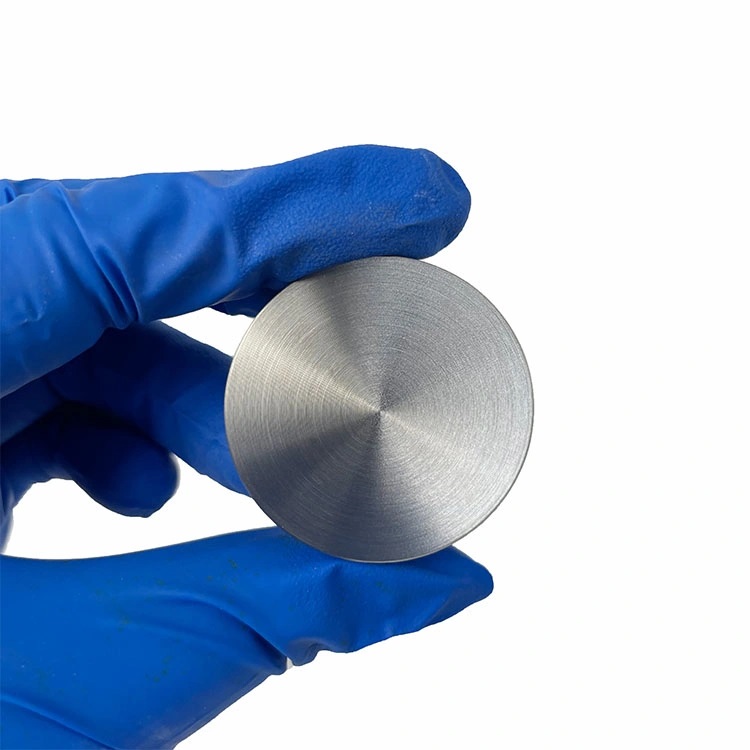

Mo Molybdenum Sputtering Target

Molybdenum sputtering targets play a crucial role in industries that require high-performance, heat-resistant, and conductive coatings. Their application in semiconductors, solar cells, flat panel displays, and aerospace components highlights the versatility and importance of molybdenum in modern technology.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum (Mo) |

| Purity | 99.95% – 99.9999% / 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 1000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum (Mo) sputtering targets play a crucial role in industries that require high-performance, heat-resistant, and conductive coatings. Their application in semiconductors, solar cells, flat panel displays, and aerospace components highlights the versatility and importance of molybdenum in modern technology.

Key Features:

- Purity: Molybdenum sputtering targets are typically available in high purity levels, such as 99.95% (3N5) or higher, to ensure the deposition of high-quality, uniform films.

- Shapes and Sizes: These targets are available in various forms, including discs, plates, and custom shapes, to suit different sputtering systems and specific application requirements.

Applications:

- Semiconductor Industry: Molybdenum is widely used in the semiconductor industry for creating thin films that serve as barrier layers, gate electrodes, and interconnects in integrated circuits (ICs) and other microelectronic devices. Its excellent conductivity and resistance to electromigration make it ideal for these applications.

- Solar Cells: Molybdenum is a critical material in the production of thin-film solar cells, such as CIGS (Copper Indium Gallium Selenide) solar cells, where it is used as a back contact layer. Its ability to form strong bonds with other materials and its stability under high temperatures contribute to the efficiency and longevity of solar cells.

- Flat Panel Displays: Molybdenum is used in the production of flat panel displays, such as LCDs and OLEDs, where it acts as an electrode material due to its high conductivity and low reactivity.

- Aerospace and Defense: Molybdenum coatings are used in aerospace and defense applications to enhance the durability and performance of components exposed to extreme conditions, such as high temperatures and corrosive environments.

- X-ray and Electron Tubes: Molybdenum’s high melting point and low vapor pressure make it an ideal material for use in X-ray and electron tubes, where it serves as a target material in X-ray generation and as components in electron tubes.

Customization Options:

- Thickness: The thickness of the molybdenum coating can be precisely controlled during the sputtering process, allowing for tailored solutions to meet specific application needs.

- Alloys: Molybdenum sputtering targets can be produced as pure molybdenum or in alloyed forms, such as molybdenum-tungsten (Mo-W) or molybdenum-rhenium (Mo-Re), depending on the desired properties of the thin film.

- Backing Plates: Molybdenum targets can be bonded to backing plates made from materials like copper or aluminum to improve thermal conductivity and mechanical stability during the sputtering process.

Molybdenum sputtering targets are essential components in physical vapor deposition (PVD) processes, used to deposit thin molybdenum films onto various substrates. Molybdenum is valued for its high melting point, excellent thermal and electrical conductivity, and strong resistance to corrosion, making it a key material in a wide range of high-tech applications, particularly in electronics, energy, and aerospace industries.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.