MoO3 (Molybdenum Trioxide) Sputtering Target

- High Work Function: MoO₃ is known for its high work function, which makes it ideal for applications requiring efficient charge injection or extraction, such as OLEDs and OPVs.

- Excellent Catalytic Properties: MoO₃ is a robust catalyst, especially in oxidation reactions, making it suitable for industrial chemical processes and catalytic thin films.

- Electrochromic Behavior: MoO₃’s ability to undergo reversible oxidation-reduction reactions makes it ideal for use in electrochromic devices.

- Optical Transparency: MoO₃ thin films can be transparent in the visible and near-infrared regions, which is beneficial for optoelectronic devices requiring transparent electrodes or coatings.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | MoO3 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

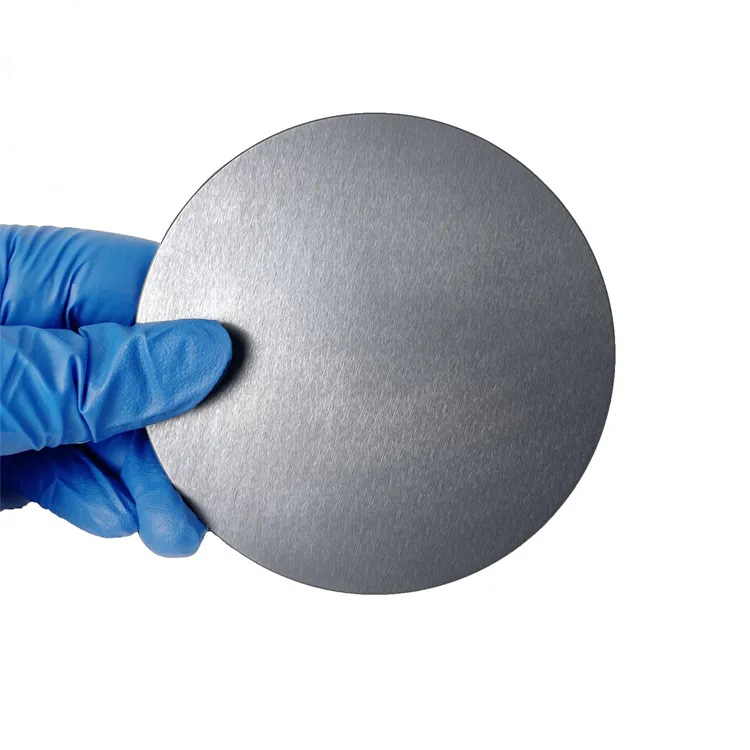

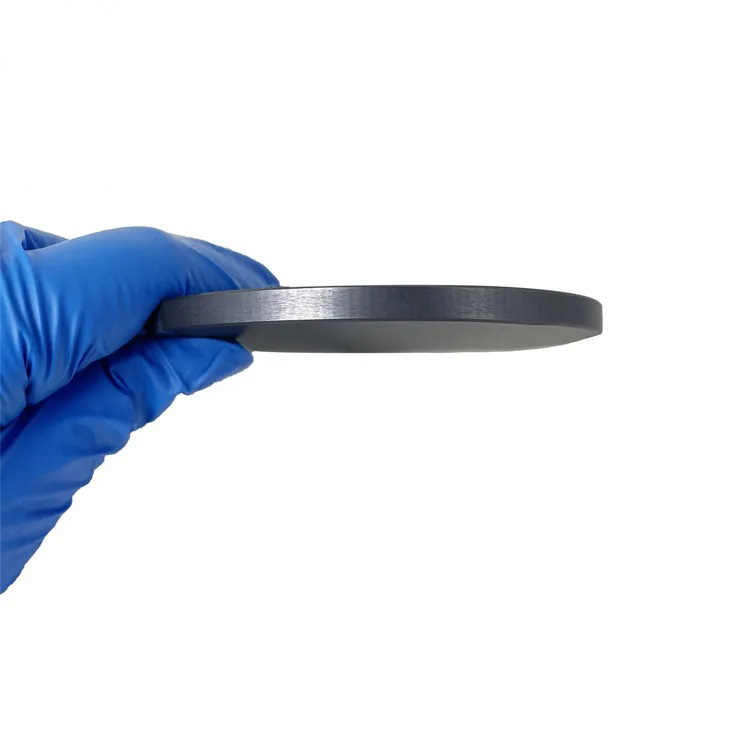

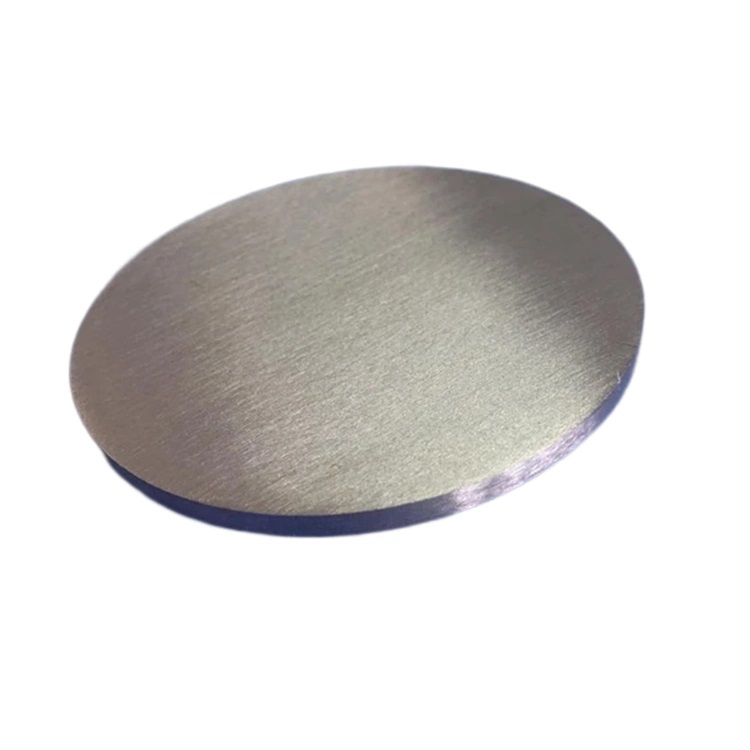

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum trioxide (MoO₃) sputtering targets are widely used in thin-film deposition for applications in electronics, catalysis, sensors, and energy storage. MoO₃ has unique electronic, optical, and catalytic properties that make it suitable for use in a variety of high-performance thin-film devices and functional coatings.

Key Applications:

- Electronics and Optoelectronics: MoO₃ thin films are utilized in electronic and optoelectronic devices such as transistors, organic light-emitting diodes (OLEDs), and organic photovoltaics (OPVs). MoO₃ serves as an efficient hole transport layer and an interface material in these devices due to its high work function and transparent conductive properties.

- Electrochromic Devices: MoO₃ is a widely studied material for use in electrochromic devices, such as smart windows and displays. Thin films of MoO₃ can change their optical properties in response to an applied voltage, allowing for dynamic control of light transmission.

- Energy Storage: MoO₃ is being explored for its potential in energy storage devices like lithium-ion batteries and supercapacitors. MoO₃ thin films are known for their high energy density and ability to enhance the electrochemical performance of battery electrodes.

- Catalysis: MoO₃ has strong catalytic properties, particularly in oxidation reactions. It is used in industrial catalysts for chemical reactions such as the production of formaldehyde and sulfur removal in petroleum refining.

- Gas Sensors: MoO₃ thin films are employed in gas sensors due to their sensitivity to various gases, including ammonia (NH₃), nitrogen dioxide (NO₂), and hydrogen sulfide (H₂S). MoO₃-based sensors exhibit fast response times and good selectivity.

Features of MoO₃ Sputtering Targets:

- High Work Function: MoO₃ is known for its high work function, which makes it ideal for applications requiring efficient charge injection or extraction, such as OLEDs and OPVs.

- Excellent Catalytic Properties: MoO₃ is a robust catalyst, especially in oxidation reactions, making it suitable for industrial chemical processes and catalytic thin films.

- Electrochromic Behavior: MoO₃’s ability to undergo reversible oxidation-reduction reactions makes it ideal for use in electrochromic devices.

- Optical Transparency: MoO₃ thin films can be transparent in the visible and near-infrared regions, which is beneficial for optoelectronic devices requiring transparent electrodes or coatings.

Customization Options:

- Target Sizes: MoO₃ sputtering targets are available in various sizes and shapes, including planar and rotary designs, to meet different sputtering system requirements.

- Purity Levels: High-purity MoO₃ targets (up to 99.99%) can be provided to ensure high-quality film deposition for critical applications.

- Doping Options: MoO₃ sputtering targets can be doped with other materials to enhance or modify the electrical, optical, or catalytic properties of the thin films.

MoO₃ (Molybdenum Trioxide) sputtering targets from Tinsan Materials are used in electronics, energy storage, electrochromic devices, and catalysis. High-purity, customizable MoO₃ targets for thin-film deposition in a wide range of advanced applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.