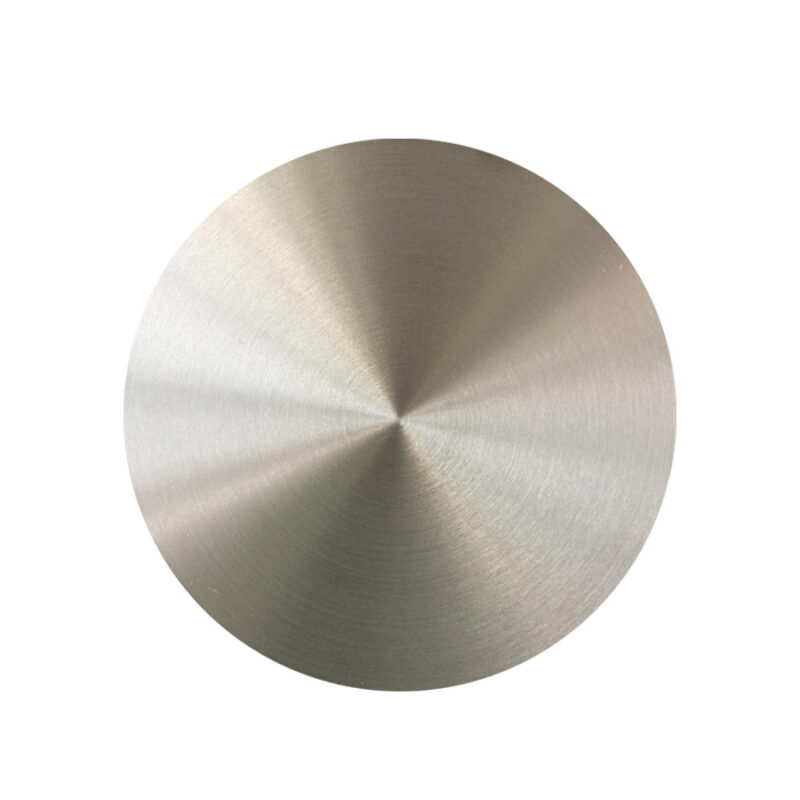

MoRe (Molybdenum Rhenium) Sputtering Targets

- High Thermal Stability: Performs exceptionally well in extreme temperature environments.

- Enhanced Ductility: Improved mechanical performance over pure molybdenum.

- Excellent Conductivity: Ensures reliable electrical and thermal performance.

- Customizable Options: Tailored to meet the specific requirements of various deposition systems.

- Corrosion Resistance: Long-lasting performance in aggressive environments.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Rhenium (MoRe) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum Rhenium (MoRe) sputtering targets are advanced alloy materials renowned for their unique combination of mechanical strength, thermal stability, and excellent conductivity. The MoRe alloy offers enhanced ductility and toughness compared to pure molybdenum, making it suitable for demanding thin-film applications in semiconductor, aerospace, and scientific research industries. Manufactured with precision and available in high-purity grades, these targets ensure optimal thin-film quality and uniformity.

Key Applications

- Semiconductor Industry: Thin-film deposition for microelectronics and MEMS devices.

- Aerospace: Coatings for high-temperature and wear-resistant applications.

- Superconductors: Thin films for advanced superconducting applications.

- Scientific Research: Material studies and advanced thin-film experiments.

Features and Benefits

- High Thermal Stability: Performs exceptionally well in extreme temperature environments.

- Enhanced Ductility: Improved mechanical performance over pure molybdenum.

- Excellent Conductivity: Ensures reliable electrical and thermal performance.

- Customizable Options: Tailored to meet the specific requirements of various deposition systems.

- Corrosion Resistance: Long-lasting performance in aggressive environments.

Specifications

- Chemical Composition: Typically 47.5% Molybdenum (Mo), 52.5% Rhenium (Re) (custom ratios available).

- Purity: ≥ 99.9%.

- Density: ~12.5 g/cm³.

- Target Shapes: Circular, rectangular, or custom geometries.

- Dimensions: Wide range of sizes to fit different sputtering systems.

Customization Options

- Alloy Ratios: Custom Mo:Re ratios for specialized applications.

- Target Sizes and Shapes: Adaptable to your specific equipment.

- Bonding Services: Backing plate bonding for efficient heat dissipation.

- Purity Grades: Ultra-high purity for research and semiconductor needs.

- Surface Finishing: Polished or machined surface finishes for optimal deposition.

Discover the versatility of Molybdenum Rhenium (MoRe) sputtering targets for high-performance thin-film applications. Contact us to learn more about our products and customization services.