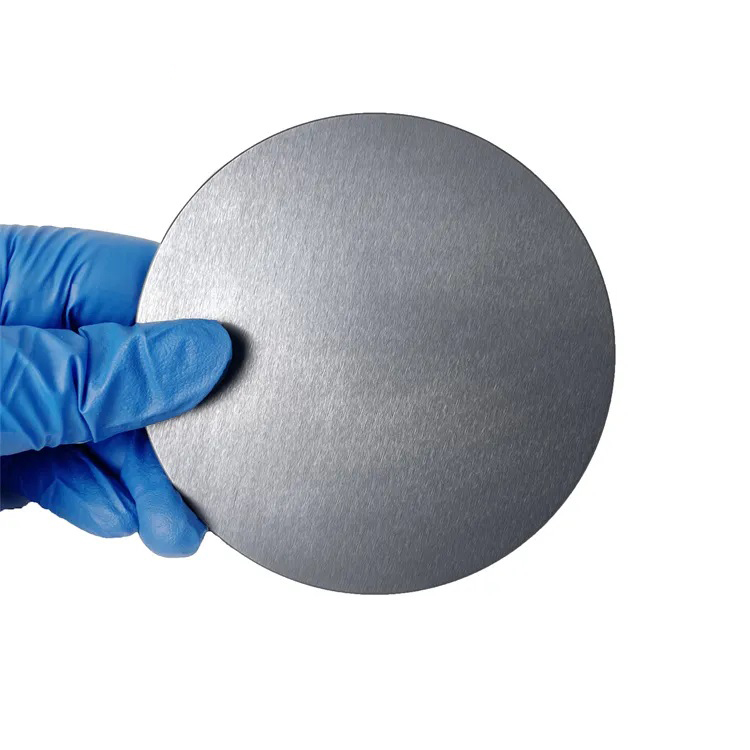

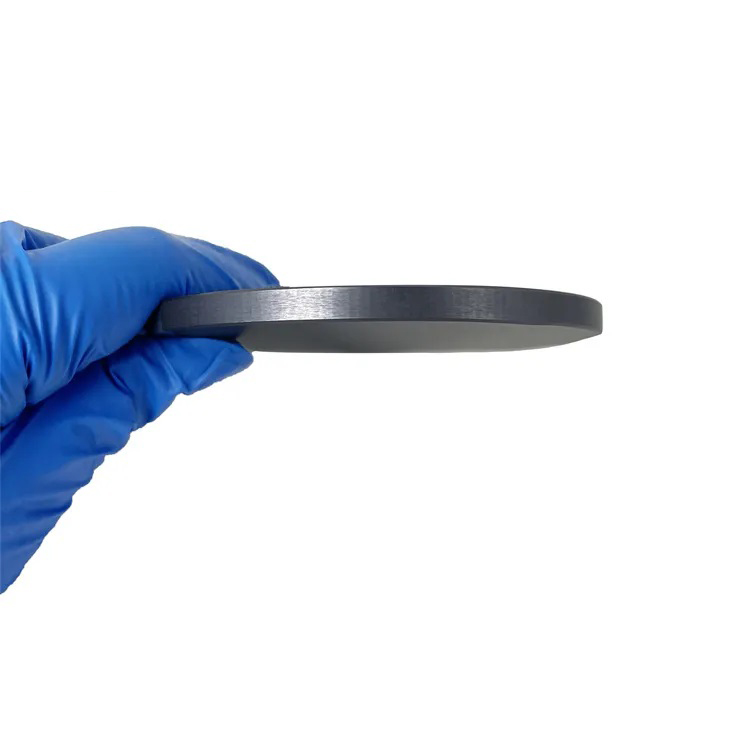

MoS2 (Molybdenum Disulfide) Sputtering Target

- Layered Structure: MoS2 has a unique layered structure that contributes to its mechanical, electrical, and tribological properties, making it an excellent candidate for advanced coatings and devices.

- Semiconducting Properties: MoS2 is a semiconductor with a direct bandgap in its monolayer form, offering high performance in electronic devices such as transistors and photodetectors.

- Low Friction Coefficient: As a solid lubricant, MoS2 provides a low friction coefficient, making it useful in harsh environments where liquid lubricants are impractical.

- High Thermal and Chemical Stability: MoS2 films exhibit excellent thermal and chemical stability, enabling their use in high-temperature environments and chemically aggressive conditions.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | MoS2 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum disulfide (MoS2) sputtering targets are used for the deposition of MoS2 thin films in a variety of advanced technological applications. MoS2 is a layered, two-dimensional material with unique electronic, lubricating, and optical properties, making it popular in fields like semiconductor manufacturing, tribology, and optoelectronics.

Key Applications:

- Semiconductors and Transistors: MoS2 is widely used in the fabrication of next-generation transistors and semiconductors due to its 2D structure and high electron mobility. MoS2 thin films offer an alternative to traditional silicon-based materials in flexible electronics and low-power devices.

- Solid Lubricants: MoS2 is known for its excellent lubricating properties, making MoS2 coatings ideal for reducing friction and wear in mechanical parts and aerospace components.

- Optoelectronics: Molybdenum disulfide is valued for its optical properties and is utilized in photodetectors, light-emitting diodes (LEDs), and solar cells. Its ability to absorb light efficiently makes it a promising material for photovoltaic applications.

- Catalysis: MoS2 thin films are also used as catalysts in chemical reactions, particularly in hydrogen evolution reactions (HER), making them important in the field of energy storage and conversion.

- Flexible Electronics: Due to its flexibility and strength, MoS2 is employed in flexible electronic devices, wearable technology, and sensors.

Features of MoS2 Sputtering Targets:

- Layered Structure: MoS2 has a unique layered structure that contributes to its mechanical, electrical, and tribological properties, making it an excellent candidate for advanced coatings and devices.

- Semiconducting Properties: MoS2 is a semiconductor with a direct bandgap in its monolayer form, offering high performance in electronic devices such as transistors and photodetectors.

- Low Friction Coefficient: As a solid lubricant, MoS2 provides a low friction coefficient, making it useful in harsh environments where liquid lubricants are impractical.

- High Thermal and Chemical Stability: MoS2 films exhibit excellent thermal and chemical stability, enabling their use in high-temperature environments and chemically aggressive conditions.

Customization Options:

- Target Dimensions: MoS2 sputtering targets are available in a range of sizes and shapes to fit different sputtering systems, including custom configurations.

- Purity Levels: High-purity MoS2 sputtering targets (up to 99.999%) are available to ensure optimal film quality for demanding semiconductor and electronic applications.

- Doping Options: MoS2 targets can be doped with other elements to tailor the electrical and optical properties for specific applications.

MoS2 (Molybdenum Disulfide) sputtering targets from Tinsan Materials are used in semiconductor, lubrication, and optoelectronic applications. Custom dimensions, high-purity options, and excellent film quality for advanced thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.