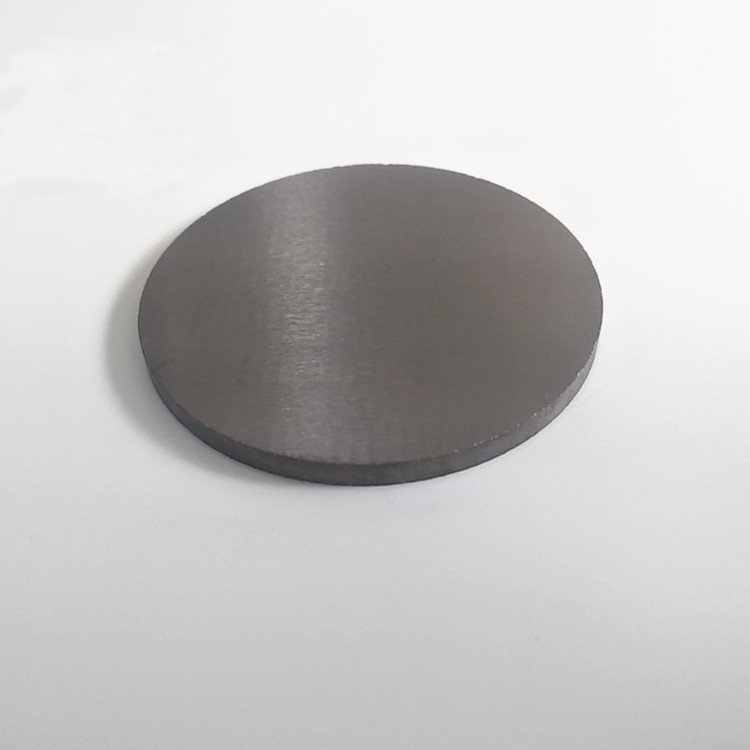

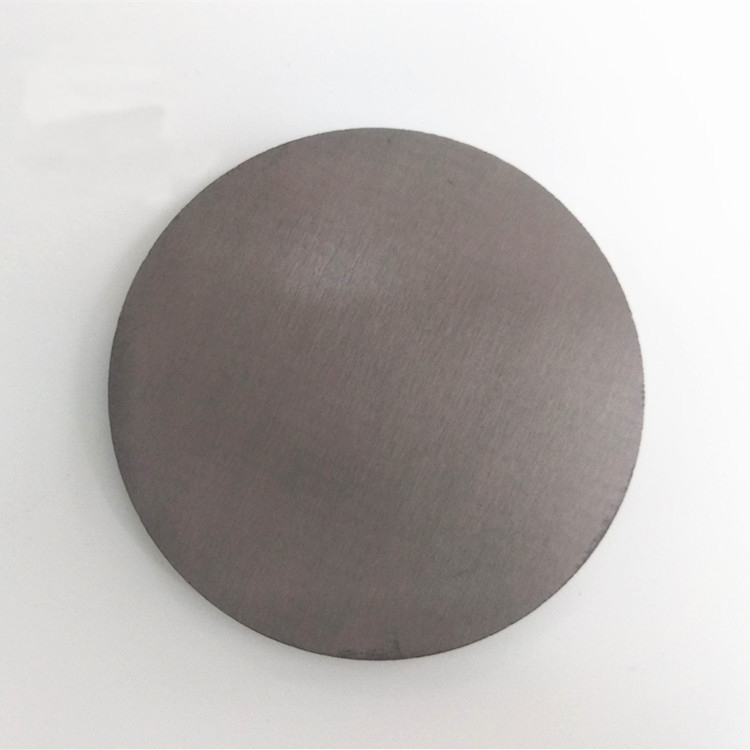

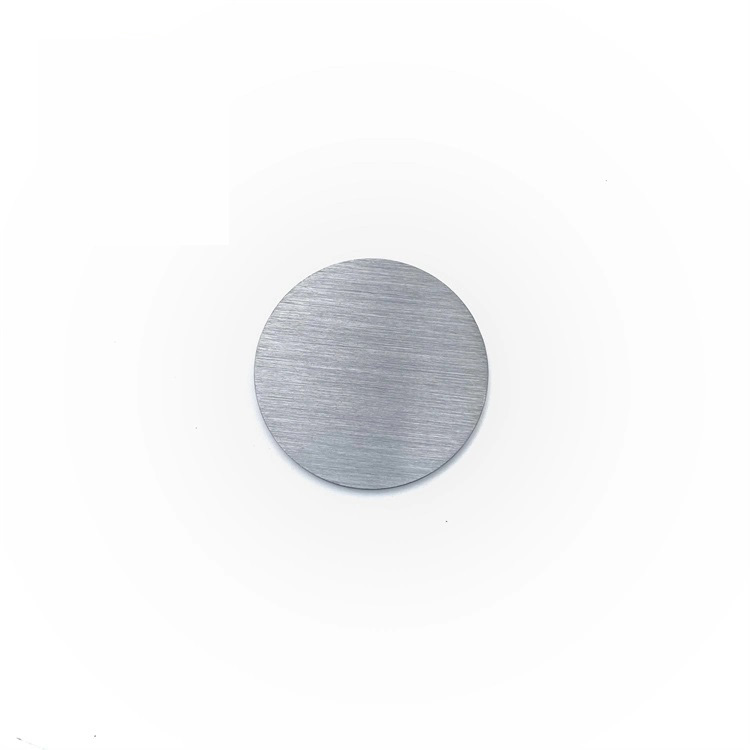

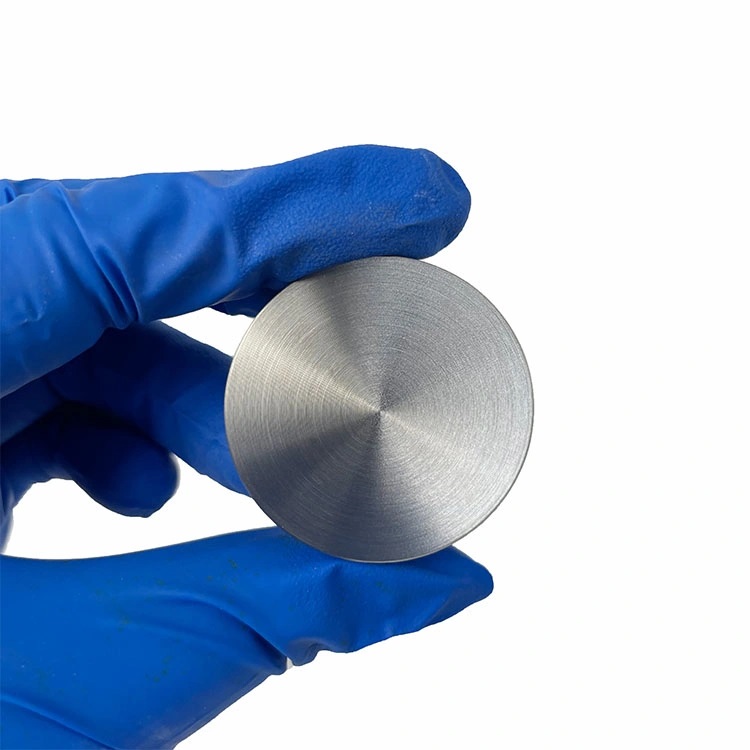

MoSe2 (Molybdenum Diselenide) Sputtering Targets

- High Purity: Ensures superior thin-film quality and device performance.

- Layered Structure: Facilitates easy exfoliation and 2D material synthesis.

- Stable Chemical Composition: Provides consistent results across various deposition processes.

- Excellent Optical and Electrical Properties: Ideal for advanced electronics and optoelectronics.

- Custom Configurations: Available in tailored sizes, shapes, and thicknesses for specific requirements.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Diselenide (MoSe₂) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum Diselenide (MoSe₂) sputtering targets are high-quality materials engineered for thin-film deposition in advanced electronics, photonics, and energy storage systems. With a layered structure and excellent semiconducting properties, MoSe₂ is a key material in the development of 2D materials, optoelectronic devices, and photovoltaic technologies.

Key Applications

- 2D Materials Research: Used in the fabrication of ultra-thin, high-performance layers for next-generation electronics.

- Optoelectronics: Essential for photodetectors, light-emitting diodes (LEDs), and modulators.

- Energy Conversion and Storage: Suitable for applications in solar cells and supercapacitors.

- Semiconductors: Provides excellent properties for transistors and integrated circuits.

- Photovoltaics: Enhances the efficiency of solar energy harvesting systems.

Features and Benefits

- High Purity: Ensures superior thin-film quality and device performance.

- Layered Structure: Facilitates easy exfoliation and 2D material synthesis.

- Stable Chemical Composition: Provides consistent results across various deposition processes.

- Excellent Optical and Electrical Properties: Ideal for advanced electronics and optoelectronics.

- Custom Configurations: Available in tailored sizes, shapes, and thicknesses for specific requirements.

Specifications

- Purity: ≥ 99.95%, ensuring minimal contamination in thin-film applications.

- Density: Optimized for uniform deposition and high material utilization.

- Dimensions: Customizable to fit a wide range of sputtering systems.

- Forms: Available in discs, plates, or other geometries as needed.

- Surface Finish: Polished to a smooth surface for consistent sputtering performance.

Customization Options

- Size and Shape Customization: Adaptable to specific equipment and process needs.

- Bonding Services: Compatible backing plates for improved thermal management.

- Special Packaging: Designed for safe handling and transportation.

- Material Variations: Compositional adjustments for specialized applications.

Discover high-quality Molybdenum Diselenide (MoSe₂) sputtering targets tailored to your thin-film deposition projects. Contact us for expert consultation, custom solutions, and prompt delivery.