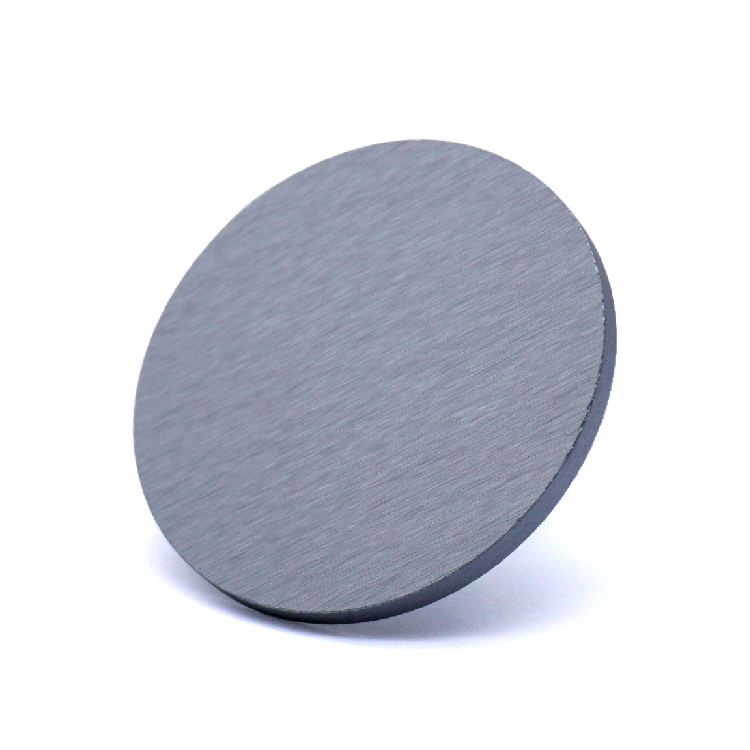

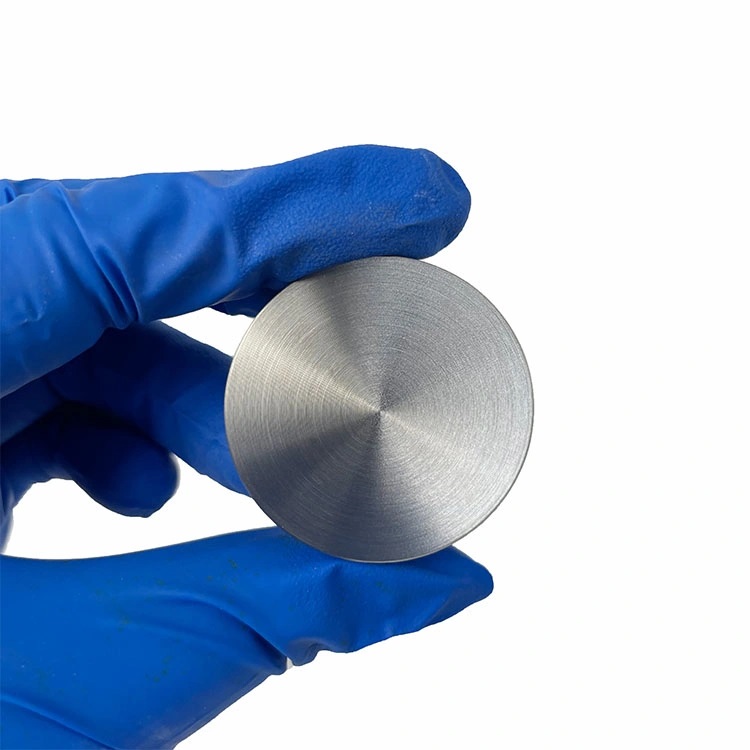

MoSi2 (Molybdenum Disilicide) Sputtering Targets

- Exceptional Thermal Stability: Operates efficiently in high-temperature environments.

- High Purity Levels: Ensures superior film quality with minimal defects.

- Oxidation Resistance: Suitable for protective coatings in harsh conditions.

- Electrical Conductivity: Ideal for use in electronic and semiconductor applications.

- Customizable Options: Targets tailored to specific industrial or research needs.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Molybdenum Disilicide (MoSi₂) |

| Purity | 99.5% – 99.9999% / 2N5 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Molybdenum Disilicide (MoSi₂) sputtering targets are high-performance materials used in thin-film deposition processes across advanced technological applications. Known for their exceptional thermal stability, electrical conductivity, and oxidation resistance, MoSi₂ sputtering targets are ideal for creating protective coatings, semiconductor devices, and high-temperature components. Their precise composition and purity levels ensure consistent, high-quality thin-film deposition.

Key Applications

- Semiconductor Industry: Thin films for microelectronics and integrated circuits.

- Protective Coatings: High-temperature oxidation-resistant coatings for industrial components.

- Energy Systems: Materials for photovoltaic cells and fuel cell components.

- Aerospace and Automotive: Coatings for thermal management and structural stability.

- Research and Development: Studies in advanced materials science and engineering.

Features and Benefits

- Exceptional Thermal Stability: Operates efficiently in high-temperature environments.

- High Purity Levels: Ensures superior film quality with minimal defects.

- Oxidation Resistance: Suitable for protective coatings in harsh conditions.

- Electrical Conductivity: Ideal for use in electronic and semiconductor applications.

- Customizable Options: Targets tailored to specific industrial or research needs.

Specifications

- Chemical Formula: MoSi₂

- Purity: ≥ 99.5% (higher purities available).

- Density: ~6.24 g/cm³

- Target Shapes: Circular, rectangular, or custom geometries.

- Sizes: Standard and customized dimensions for compatibility with various sputtering systems.

Customization Options

- Shape and Size Variations: Targets designed to fit unique sputtering setups.

- Enhanced Purity: Ultra-high purity versions available for critical applications.

- Backing Plate Integration: Optional for improved heat dissipation and mechanical support.

- Custom Compositions: Modified formulations to meet specific application requirements.

Discover the ideal Molybdenum Disilicide (MoSi₂) sputtering targets for your thin-film deposition needs. Reach out to our team for expert guidance, custom solutions, and reliable delivery tailored to your exact specifications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.