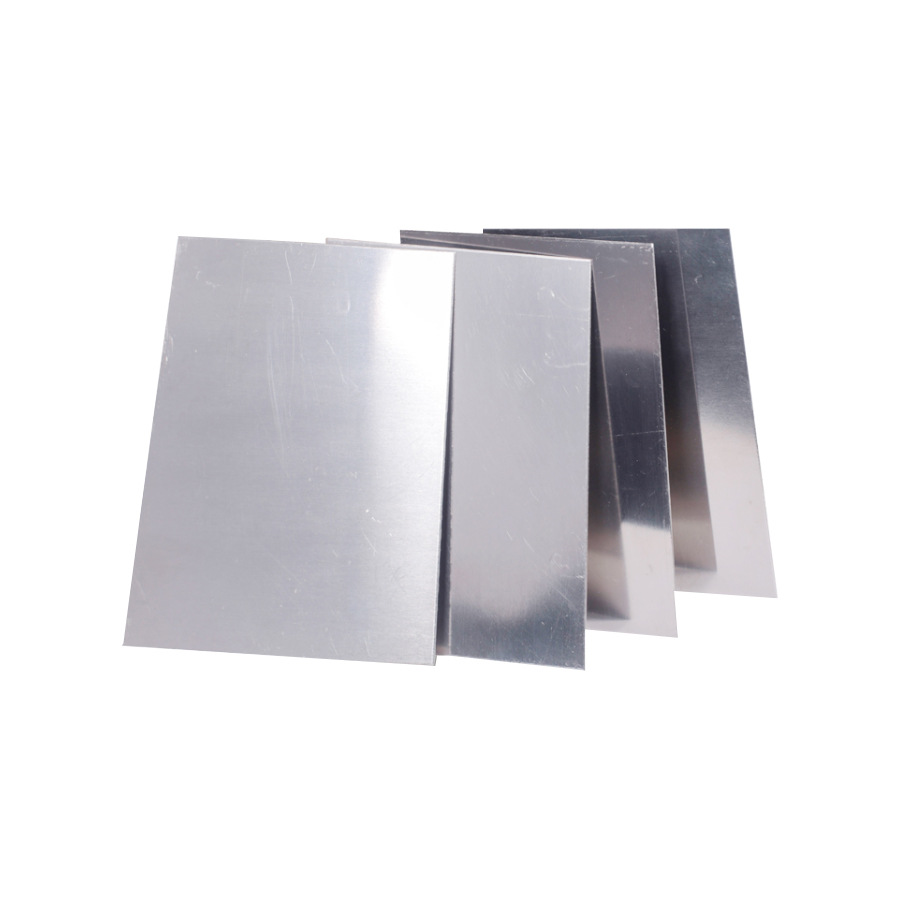

Nb Niobium Foil

- High Corrosion Resistance: Niobium foil offers exceptional resistance to corrosion, particularly in acidic environments. It forms a stable oxide layer on its surface, protecting it from further corrosion in harsh chemicals and high-temperature conditions.

- High Melting Point: Niobium has a high melting point of around 2,468°C (4,474°F), making it suitable for high-temperature applications, such as those in the aerospace and automotive industries.

- Excellent Ductility and Malleability: Niobium foil is highly ductile and malleable, allowing it to be easily formed into thin, flexible sheets without compromising its mechanical properties. This makes it ideal for custom fabrication in precision applications.

- Low Thermal Expansion: Niobium has a relatively low coefficient of thermal expansion, which ensures that it maintains stability and does not deform easily under thermal stress. This property is beneficial in applications requiring high thermal stability.

- Biocompatibility: Niobium is biocompatible and is often used in medical implants and devices, such as pacemakers and stents, without causing adverse reactions in the human body.

- Superconductivity: Niobium exhibits superconducting properties at low temperatures, making it useful in various scientific and medical applications, such as MRI machines and particle accelerators.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Niobium foil is a highly versatile metal material known for its excellent corrosion resistance, high melting point, and strong mechanical properties. Niobium is often used in high-performance industries such as aerospace, electronics, and medical applications due to its unique combination of properties. At Tinsan Materials, we provide high-quality niobium foil for various demanding applications.

Properties of Niobium Foil

- High Corrosion Resistance: Niobium foil offers exceptional resistance to corrosion, particularly in acidic environments. It forms a stable oxide layer on its surface, protecting it from further corrosion in harsh chemicals and high-temperature conditions.

- High Melting Point: Niobium has a high melting point of around 2,468°C (4,474°F), making it suitable for high-temperature applications, such as those in the aerospace and automotive industries.

- Excellent Ductility and Malleability: Niobium foil is highly ductile and malleable, allowing it to be easily formed into thin, flexible sheets without compromising its mechanical properties. This makes it ideal for custom fabrication in precision applications.

- Low Thermal Expansion: Niobium has a relatively low coefficient of thermal expansion, which ensures that it maintains stability and does not deform easily under thermal stress. This property is beneficial in applications requiring high thermal stability.

- Biocompatibility: Niobium is biocompatible and is often used in medical implants and devices, such as pacemakers and stents, without causing adverse reactions in the human body.

- Superconductivity: Niobium exhibits superconducting properties at low temperatures, making it useful in various scientific and medical applications, such as MRI machines and particle accelerators.

Advantages of Niobium Foil

- High Durability and Longevity: Niobium foil’s resistance to corrosion and high melting point make it highly durable and able to withstand extreme environments. This durability ensures a longer service life and reduces the need for frequent replacements.

- Enhanced Performance in Harsh Environments: Due to its high-temperature resistance and corrosion resistance, niobium foil can perform optimally in demanding environments, such as high-temperature processing, vacuum systems, and harsh chemical settings.

- Customizable and Easy to Fabricate: Niobium foil can be customized in terms of thickness, width, and other specifications to suit specific applications. Its malleability and ductility make it easy to fabricate into custom shapes, ensuring compatibility with various designs and technologies.

- Lightweight yet Strong: Niobium foil offers a unique balance between strength and weight, which is important in industries where weight is a critical factor, such as aerospace and automotive industries.

- Non-toxic and Biocompatible: Niobium is non-toxic and has no known harmful effects on human health, making it a safe choice for medical devices and implants that come in direct contact with the human body.

Applications of Niobium Foil

- Aerospace and Aviation: Niobium foil is used in aerospace applications due to its high melting point, corrosion resistance, and lightweight properties. It is often used in rocket nozzles, turbine blades, and heat shields where extreme temperatures and durability are required.

- Electronics and Capacitors: Niobium foil is used in the production of electronic components, including capacitors and superconducting magnets. Its excellent conductivity and superconducting properties make it ideal for these applications.

- Medical Devices and Implants: Due to its biocompatibility, niobium foil is used in medical implants such as pacemakers, stents, and dental devices. Its resistance to corrosion and ability to function well in the human body make it a safe and reliable material for medical applications.

- Nuclear Industry: Niobium’s ability to withstand extreme temperatures and resist radiation damage makes it a material of choice for nuclear reactors, where it is used in fuel rods and other reactor components.

- Chemical Processing: Niobium foil is used in chemical processing equipment, particularly in highly corrosive environments. Its resistance to acids and other aggressive chemicals ensures it remains durable and functional over extended periods.

- Superconducting Applications: Niobium foil is widely used in superconducting applications, such as in MRI machines, particle accelerators, and fusion research, due to its superconducting properties at low temperatures.

- Jewelry and Watchmaking: Niobium’s unique colors and resistance to tarnish make it popular in jewelry and watchmaking. Niobium foil can be used to create durable and aesthetically pleasing designs.

Customization and Manufacturing of Niobium Foil

At Tinsan Materials, we specialize in the production of high-quality niobium foil. Our materials can be customized in thickness, size, and finish to meet specific application requirements. Whether you need niobium foil for aerospace, electronics, medical devices, or any other industry, we ensure that every product meets stringent quality standards for performance and reliability.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.