Nb Niobium Wires

- High Corrosion Resistance: Exhibits outstanding resistance to chemicals, acids, and oxidizing agents, even in extreme environments.

- Biocompatibility: Completely inert and non-reactive with body tissues, making it ideal for medical implants and devices.

- Superconductivity: Niobium becomes superconductive at low temperatures, making it essential for advanced scientific and electrical applications.

- Ductility and Malleability: Highly ductile and can be drawn into fine wires or shaped to meet specific requirements.

- High Melting Point: With a melting point of 2477°C, niobium wire maintains its integrity under extreme heat.

- Oxidation Resistance: Forms a stable oxide layer that enhances its resistance to further oxidation and wear.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

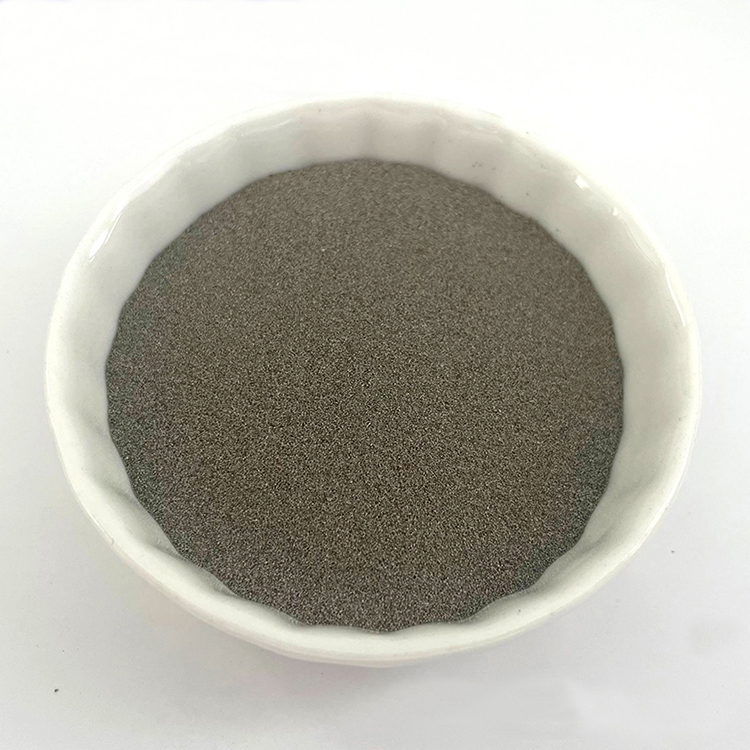

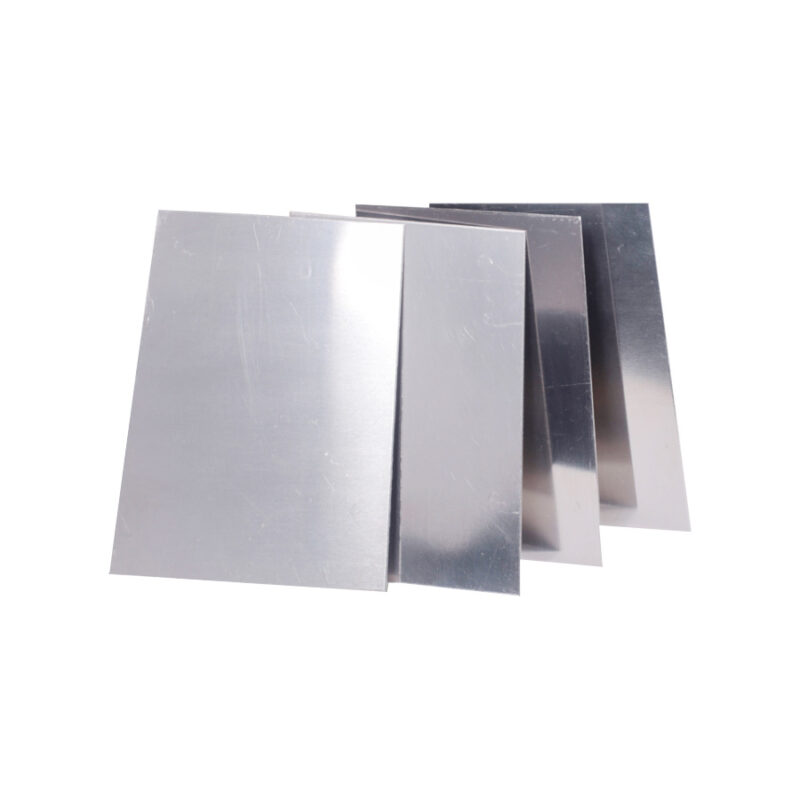

Niobium wire is a unique and versatile material widely used across various industries due to its remarkable properties, including exceptional corrosion resistance, biocompatibility, and superconducting capabilities. These attributes make it indispensable in applications ranging from medical implants to advanced scientific research.

Properties of Niobium Wire

- High Corrosion Resistance: Exhibits outstanding resistance to chemicals, acids, and oxidizing agents, even in extreme environments.

- Biocompatibility: Completely inert and non-reactive with body tissues, making it ideal for medical implants and devices.

- Superconductivity: Niobium becomes superconductive at low temperatures, making it essential for advanced scientific and electrical applications.

- Ductility and Malleability: Highly ductile and can be drawn into fine wires or shaped to meet specific requirements.

- High Melting Point: With a melting point of 2477°C, niobium wire maintains its integrity under extreme heat.

- Oxidation Resistance: Forms a stable oxide layer that enhances its resistance to further oxidation and wear.

Advantages of Niobium Wire

- Durability: Long-lasting performance in harsh environments, thanks to its high corrosion and oxidation resistance.

- Versatility: Applicable in a wide range of fields, from aerospace to medical technology.

- Superconducting Capabilities: Ideal for cutting-edge technologies like particle accelerators and MRI machines.

- Customizability: Available in various dimensions, purities, and finishes to suit diverse applications.

- Eco-Friendly: Niobium is non-toxic and recyclable, aligning with sustainability goals.

Applications of Niobium Wire

- Medical Devices and Implants: Used in pacemakers, orthopedic implants, and dental devices due to its biocompatibility and non-toxic nature.

- Superconductors: Essential in the manufacture of superconducting magnets for particle accelerators, MRI scanners, and quantum computing.

- Aerospace Industry: Incorporated into jet engines and rocket components for its heat resistance and durability under extreme conditions.

- Chemical Processing: Utilized in corrosive environments such as reactors and heat exchangers for its chemical inertness.

- Jewelry: Popular for creating hypoallergenic and corrosion-resistant jewelry designs.

- Electronics: Used in capacitors and other electronic components for its stable electrical properties.

- Energy Storage: Integrated into advanced battery systems and hydrogen storage applications due to its unique material properties.

Customization Options

- Dimensions: Niobium wire is available in various diameters and lengths to match specific industrial needs.

- Purity Levels: Can be supplied in ultra-high-purity grades for specialized scientific and technical applications.

- Surface Treatments: Includes polished, oxidized, or coated finishes to enhance performance in specific environments.

Tinsan Materials offers top-quality niobium wire tailored for diverse applications, ensuring consistent performance through rigorous quality controls and state-of-the-art manufacturing.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.