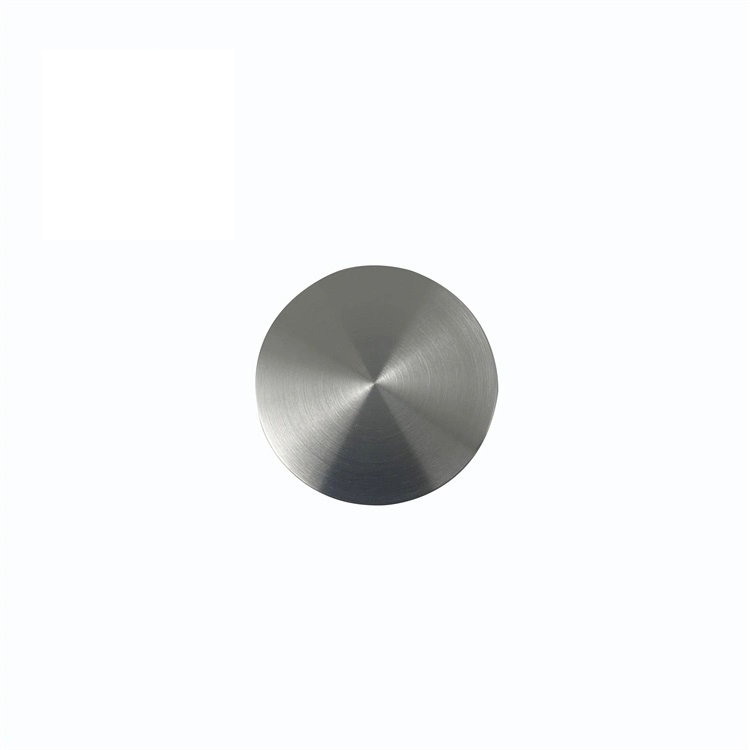

NiCr (Nickel Chromium) Alloy Target

- High Electrical Resistivity: NiCr alloy is valued for its stable and reliable electrical resistivity, making it ideal for resistive coatings in electronic devices.

- Oxidation and Corrosion Resistance: Chromium in the alloy provides excellent resistance to oxidation and corrosion, especially at elevated temperatures, ensuring longevity in harsh conditions.

- Thermal Stability: NiCr retains its mechanical and electrical properties under extreme heat, making it suitable for applications involving high temperatures, such as heating elements.

- Customizable Composition: The ratio of nickel and chromium can be adjusted to optimize properties like electrical conductivity or resistance to oxidation, depending on the specific application.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Chromium |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

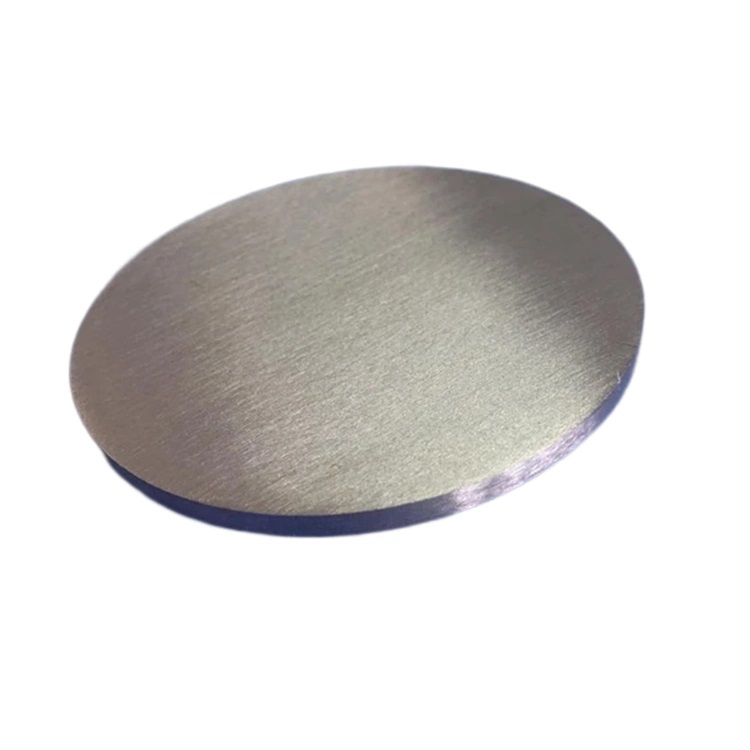

Nickel-Chromium (NiCr) alloy sputtering targets are widely used for their excellent combination of electrical resistivity, corrosion resistance, and high-temperature stability. NiCr is a popular material in thin-film deposition applications due to its ability to produce durable, conductive, and oxidation-resistant coatings.

Key Applications:

- Thin-Film Resistors: NiCr alloy is commonly used in the fabrication of thin-film resistors because of its stable and predictable electrical resistivity, even under high temperatures.

- Microelectronics: NiCr thin films are frequently applied in microelectronic devices such as integrated circuits (ICs), sensors, and MEMS, where precision and reliability are critical.

- Heating Elements: Due to its high melting point and excellent heat resistance, NiCr alloy is used in heating elements for industrial equipment and consumer devices.

- Semiconductor Devices: NiCr is employed in semiconductor devices for its conductivity, temperature stability, and long-lasting performance in electronic components.

- Protective Coatings: NiCr alloy provides robust protective coatings for surfaces exposed to high temperatures and corrosive environments, such as in aerospace and industrial equipment.

Features of NiCr Alloy Sputtering Targets:

- High Electrical Resistivity: NiCr alloy is valued for its stable and reliable electrical resistivity, making it ideal for resistive coatings in electronic devices.

- Oxidation and Corrosion Resistance: Chromium in the alloy provides excellent resistance to oxidation and corrosion, especially at elevated temperatures, ensuring longevity in harsh conditions.

- Thermal Stability: NiCr retains its mechanical and electrical properties under extreme heat, making it suitable for applications involving high temperatures, such as heating elements.

- Customizable Composition: The ratio of nickel and chromium can be adjusted to optimize properties like electrical conductivity or resistance to oxidation, depending on the specific application.

Customization Options:

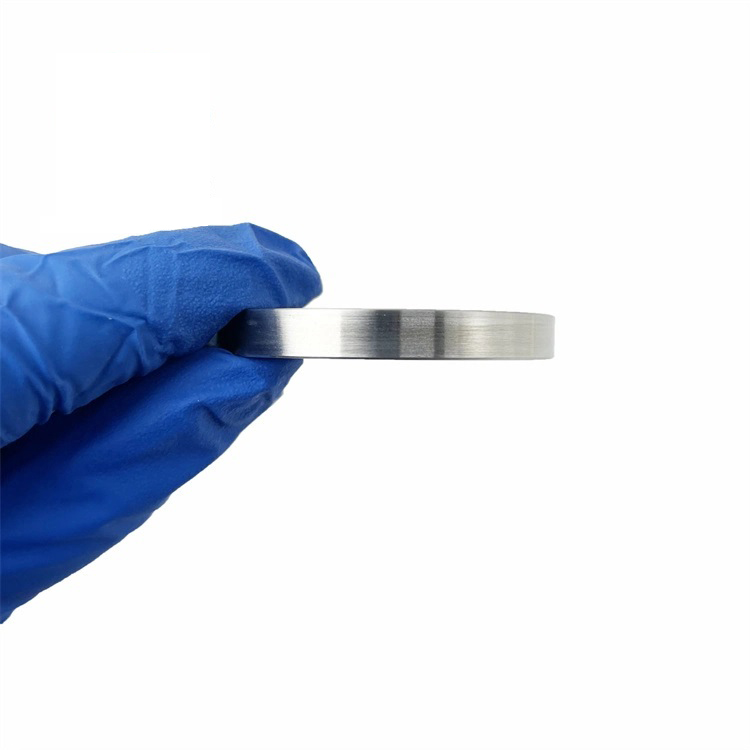

- Dimensions: NiCr sputtering targets are available in a variety of sizes and shapes, including discs, plates, and custom geometries, tailored to meet specific deposition system requirements.

- Purity Levels: High-purity NiCr alloy sputtering targets (up to 99.99%) are offered for use in demanding applications, such as semiconductor manufacturing and advanced electronics.

- Composition Adjustments: The ratio of nickel to chromium can be customized to achieve the desired resistivity, corrosion resistance, or temperature performance.

NiCr alloy sputtering targets from Tinsan Materials provide excellent electrical resistivity, corrosion resistance, and thermal stability for thin-film resistors, microelectronics, and heating elements. Custom sizes and compositions available for optimal thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.