NiCr (Nickel Chromium) Pellets Granules Evaporation Materials

- High purity (≥99.9%).

- Outstanding electrical resistivity and thermal stability.

- Exceptional corrosion and oxidation resistance.

- Uniform pellet size for consistent deposition rates.

- Suitable for PVD and CVD thin-film deposition.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Chromium (NiCr) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

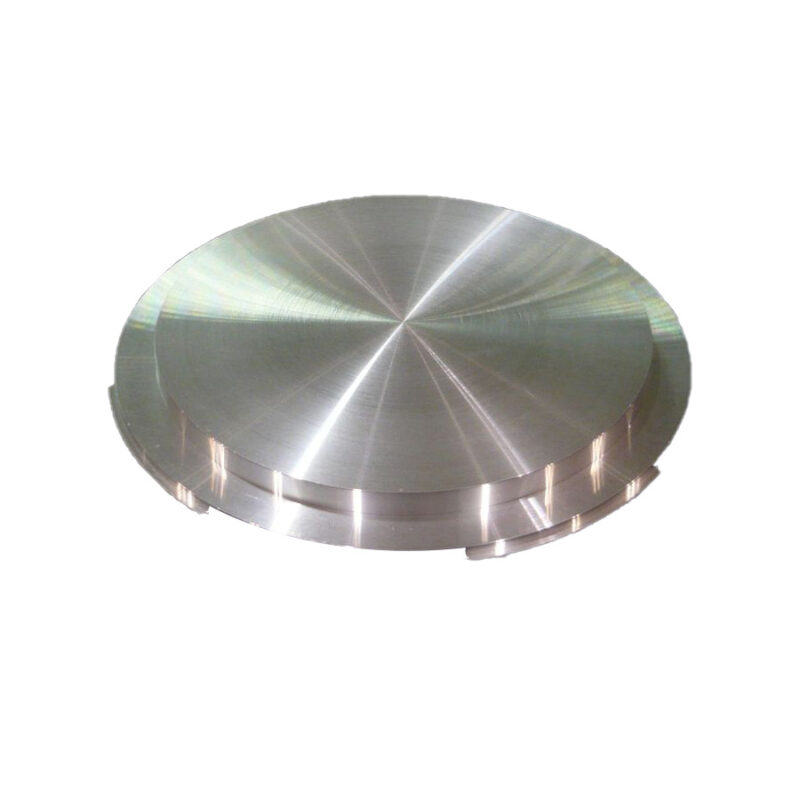

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

NiCr Pellets (Nickel-Chromium Pellets) are high-purity alloy materials extensively used in thin-film deposition, electronics, and thermal applications. Known for their excellent electrical resistance, thermal stability, and corrosion resistance, NiCr Pellets are essential for producing precision coatings and advanced electronic components. These pellets are optimized for applications such as PVD and CVD processes, thermocouples, and heater elements.

Key Features

- High purity (≥99.9%).

- Outstanding electrical resistivity and thermal stability.

- Exceptional corrosion and oxidation resistance.

- Uniform pellet size for consistent deposition rates.

- Suitable for PVD and CVD thin-film deposition.

Technical Specifications

① Chemical Composition

- Nickel (Ni) and Chromium (Cr) Content: Alloy ratio customizable (e.g., 80:20, 70:30).

- Purity: ≥99.9%.

- Trace Impurities: Minimal and available upon request.

② Physical Properties

- Appearance: Metallic pellets with a silver-gray color.

- Density: ~8.4 g/cm³ (varies with alloy ratio).

- Melting Point: ~1350°C (varies with composition).

③ Pellet Size

- Standard Sizes: 1-3 mm, 3-5 mm.

- Custom sizes available upon request.

Applications

- Thin-Film Deposition: Ideal for PVD and CVD processes to produce thin, uniform coatings for semiconductors, sensors, and resistors.

- Thermal Elements: Widely used in manufacturing heating elements and resistive wire components due to excellent thermal stability.

- Thermocouples: Utilized in Type K thermocouples for accurate temperature measurement in various industrial environments.

- Corrosion-Resistant Coatings: Applied in aerospace, automotive, and industrial sectors to enhance component durability.

- Research and Development: Preferred material for studies on advanced alloy performance and deposition technologies.

Product Advantages

- High Stability: Excellent resistance to thermal and chemical degradation.

- Customizable Composition: Tailored alloy ratios to meet specific requirements.

- Reliable Performance: Uniform pellet size ensures consistent deposition results.

- Versatility: Suitable for a wide range of applications in electronics, aerospace, and industrial sectors.

- Environmentally Robust: Resistant to oxidation and corrosion, even in harsh environments.

Packaging and Storage

① Packaging

- Vacuum-sealed, moisture-resistant containers.

- Custom packaging available upon request.

② Storage

- Store in a cool, dry environment.

- Keep sealed to prevent contamination or oxidation.

Quality Certifications

- ISO 9001 Certified Quality Management System.

- RoHS Compliance.

- Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS) available upon request.

For further details or to request a quote, please contact us. Our team is ready to provide high-quality materials and tailored solutions for your advanced manufacturing and research requirements.