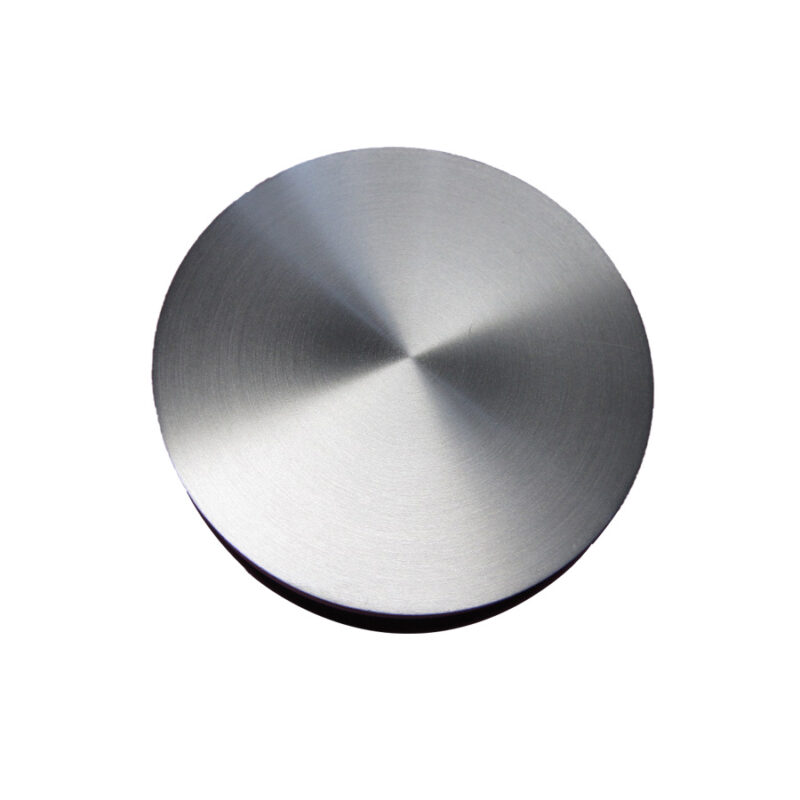

NiCu (Nickel Copper) Alloy Target

- High Electrical Conductivity: NiCu alloy sputtering targets offer excellent electrical conductivity, making them ideal for thin films in electronic devices where efficient current flow is essential.

- Corrosion Resistance: The combination of nickel and copper provides strong corrosion resistance, allowing the thin films to withstand exposure to chemicals and harsh environments, such as marine and industrial settings.

- Magnetic Properties: NiCu alloys exhibit useful magnetic properties, which can be tailored for specific applications such as sensors, transformers, and other magnetic devices.

- Thermal Stability: NiCu alloy thin films maintain their structural integrity at elevated temperatures, making them suitable for high-temperature applications in aerospace and industrial settings.

- Customizable Composition: The ratio of nickel to copper can be adjusted to optimize the properties of the thin film for specific applications, such as enhancing conductivity or corrosion resistance.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Cuprum |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Nickel-Copper (NiCu) alloy sputtering targets are highly valued for their excellent combination of electrical conductivity, corrosion resistance, and magnetic properties. These targets are commonly used in industries such as electronics, magnetics, and corrosion-resistant coatings, providing durable and conductive thin films for a range of applications.

Key Applications:

- Electronics: NiCu alloy thin films are used in electronic components like integrated circuits, resistors, and printed circuit boards (PCBs), where they provide high electrical conductivity and corrosion resistance.

- Magnetic Devices: NiCu alloys are utilized in the production of magnetic devices such as sensors, inductors, and transformers due to their magnetic permeability and electrical conductivity, enhancing the performance of these devices.

- Corrosion-Resistant Coatings: The alloy is often used in applications requiring corrosion resistance, including marine environments and chemical processing equipment, where NiCu thin films protect surfaces from corrosion.

- Aerospace: In aerospace applications, NiCu thin films provide durable coatings for components exposed to harsh conditions, including high temperatures and corrosive environments, ensuring long-term reliability.

- Plating and Coatings: NiCu alloy sputtering targets are widely used in electroplating and surface finishing applications, offering decorative and protective coatings for consumer electronics and automotive components.

Features of NiCu Alloy Sputtering Targets:

- High Electrical Conductivity: NiCu alloy sputtering targets offer excellent electrical conductivity, making them ideal for thin films in electronic devices where efficient current flow is essential.

- Corrosion Resistance: The combination of nickel and copper provides strong corrosion resistance, allowing the thin films to withstand exposure to chemicals and harsh environments, such as marine and industrial settings.

- Magnetic Properties: NiCu alloys exhibit useful magnetic properties, which can be tailored for specific applications such as sensors, transformers, and other magnetic devices.

- Thermal Stability: NiCu alloy thin films maintain their structural integrity at elevated temperatures, making them suitable for high-temperature applications in aerospace and industrial settings.

- Customizable Composition: The ratio of nickel to copper can be adjusted to optimize the properties of the thin film for specific applications, such as enhancing conductivity or corrosion resistance.

Customization Options:

- Dimensions: NiCu sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit different deposition systems and application requirements.

- Purity Levels: High-purity NiCu alloy sputtering targets (up to 99.99%) are offered for critical applications in electronics, aerospace, and corrosion-resistant coatings.

- Composition Adjustments: The nickel-to-copper ratio in the alloy can be customized to meet the performance needs of different industries, ensuring optimal electrical, magnetic, and corrosion-resistant properties.

NiCu alloy sputtering targets from Tinsan Materials offer excellent electrical conductivity, corrosion resistance, and magnetic properties for electronics, aerospace, and corrosion-resistant coatings. Custom sizes and compositions available for optimized thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.