NiFe (Nickel Iron) Pellets Granules Evaporation Materials

- High purity (≥99.9%).

- Excellent magnetic and thermal properties.

- Superior corrosion and oxidation resistance.

- Uniform size for consistent evaporation rates.

- Customizable NiFe alloy ratios (e.g., 80:20, 70:30).

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Iron (NiFe) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

NiFe Pellets (Nickel Iron Pellets) are premium alloy materials designed for advanced thin-film deposition applications. Combining the magnetic properties of iron with the corrosion resistance of nickel, NiFe Pellets are a preferred choice for producing precision coatings in magnetic recording, electronic devices, and MEMS applications. Their consistent composition and high purity make them ideal for Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) processes.

Key Features

- High purity (≥99.9%).

- Excellent magnetic and thermal properties.

- Superior corrosion and oxidation resistance.

- Uniform size for consistent evaporation rates.

- Customizable NiFe alloy ratios (e.g., 80:20, 70:30).

Technical Specifications

① Chemical Composition

- Nickel (Ni) and Iron (Fe) Content: Customizable alloy ratios.

- Purity: ≥99.9%.

- Trace Impurities: Minimal, available upon request.

② Physical Properties

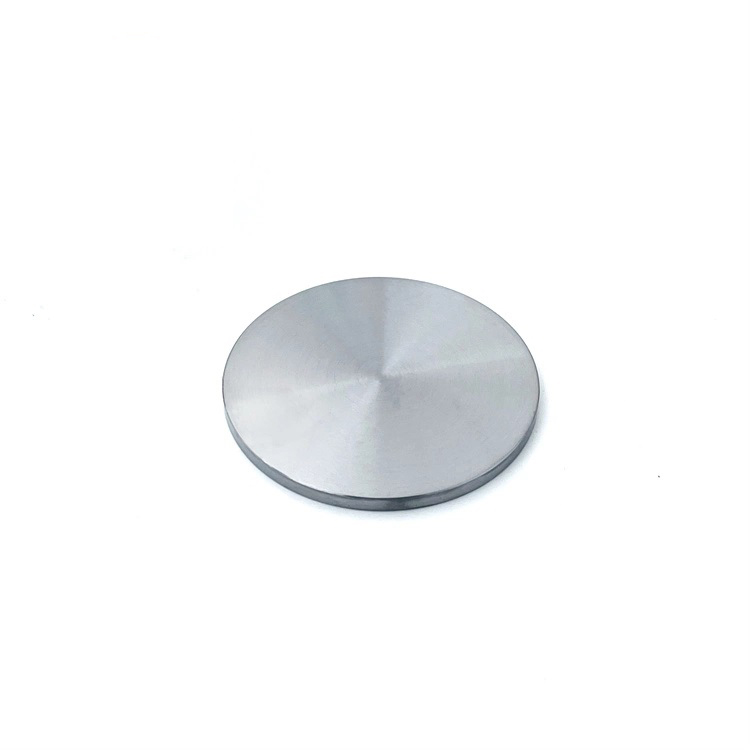

- Appearance: Metallic pellets with a silver-gray color.

- Density: ~8.6 g/cm³ (varies with alloy composition).

- Melting Point: ~1450°C (dependent on composition).

③ Pellet Size

- Standard Sizes: 1-3 mm, 3-5 mm.

- Custom sizes available upon request.

Applications

- Thin-Film Deposition: Used in PVD and CVD processes to create thin, uniform magnetic coatings for hard drives and sensors.

- Magnetic Recording: Essential for manufacturing magnetic storage devices like HDDs and MRAMs due to excellent magnetic properties.

- MEMS Devices: Enables precision coatings in microelectromechanical systems for improved performance and reliability.

- Electronic Components: Applied in the production of resistors, capacitors, and electromagnetic shielding.

- Research and Development: Suitable for experiments in alloy performance, deposition techniques, and magnetic material advancements.

Product Advantages

- High Performance: Combines excellent magnetic properties with corrosion resistance.

- Customizable Composition: Flexible alloy ratios to meet specific project needs.

- Consistent Quality: Uniform pellet size ensures reliable deposition results.

- Versatility: Applicable in electronics, data storage, and advanced manufacturing industries.

- Long-Lasting: Durable and resistant to oxidation and harsh environmental conditions.

Packaging and Storage

① Packaging

- Vacuum-sealed, moisture-resistant containers.

- Custom packaging options available upon request.

② Storage

- Store in a dry, cool environment.

- Keep sealed to prevent contamination or oxidation.

Quality Certifications

- ISO 9001 Certified Quality Management System.

- RoHS Compliance.

- Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS) available upon request.

For more information or to place an order, please contact us. Our team is dedicated to providing high-quality materials and tailored solutions for your advanced manufacturing and research needs.