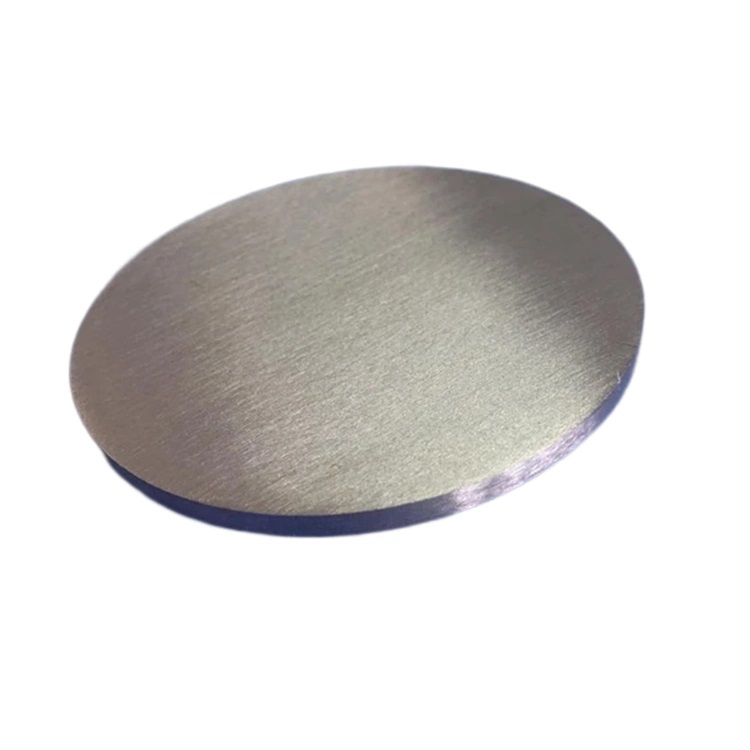

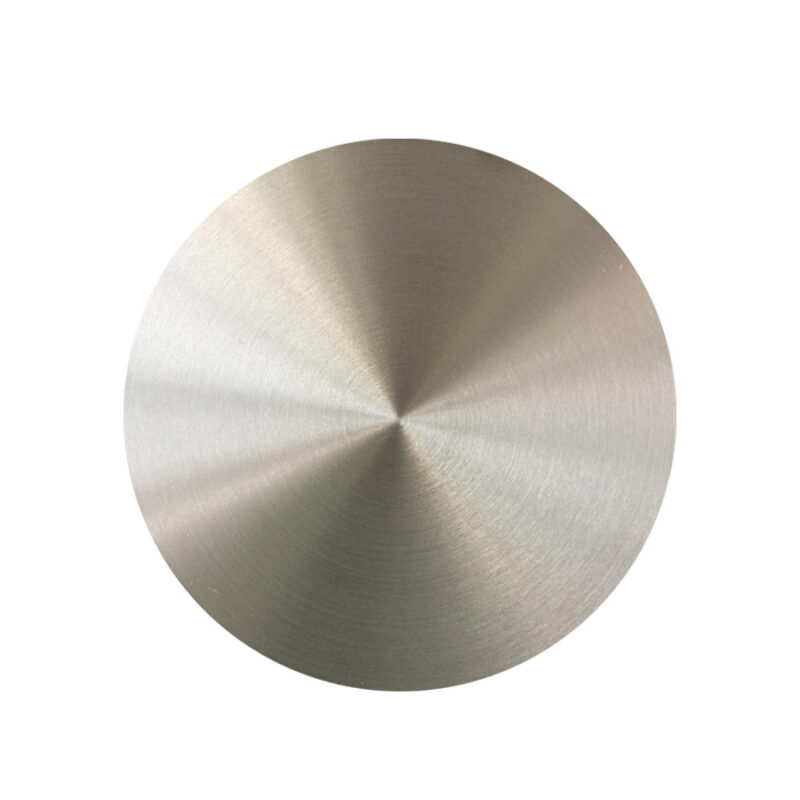

NiFeCo (Nickel Iron Cobalt) Sputtering Targets

- Magnetic Properties: Excellent for creating films with high permeability and magnetization.

- High Purity: Ensures minimal contamination and precise film deposition.

- Durability: Resistant to corrosion and wear, enhancing the lifespan of the coated components.

- Versatility in Applications: Suitable for a wide range of industrial applications in electronics and sensors.

- Customization: Custom compositions and sizes available to meet specific requirements.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Iron Cobalt (NiFeCo) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Nickel Iron Cobalt (NiFeCo) sputtering targets are composite targets made from a combination of nickel, iron, and cobalt. These targets are used in a variety of thin-film deposition applications due to their magnetic properties, durability, and versatility. NiFeCo alloys are particularly effective in producing magnetic films and coatings, often used in the manufacturing of electronic components, sensors, and data storage devices. They are available in high-purity grades, ensuring uniform deposition and high-performance results.

Key Applications

- Magnetic Films: Used for magnetic storage devices, hard disk drives, and sensors.

- Electronics: Ideal for components requiring magnetic shielding and high permeability.

- Thin Film Coatings: Applied in various industries for corrosion-resistant coatings and wear-resistant applications.

- Spintronic Devices: Employed in the production of advanced spintronic materials and devices.

- Data Storage: Suitable for magnetic recording media and memory devices.

Features and Benefits

- Magnetic Properties: Excellent for creating films with high permeability and magnetization.

- High Purity: Ensures minimal contamination and precise film deposition.

- Durability: Resistant to corrosion and wear, enhancing the lifespan of the coated components.

- Versatility in Applications: Suitable for a wide range of industrial applications in electronics and sensors.

- Customization: Custom compositions and sizes available to meet specific requirements.

Specifications

- Chemical Composition: Nickel (Ni), Iron (Fe), Cobalt (Co) alloy.

- Purity: ≥ 99.9% (standard), higher purity grades available upon request.

- Target Forms: Available in circular, rectangular, and custom shapes.

- Density: Varies based on composition and specific alloy used.

- Thickness: Available in various thicknesses to accommodate different sputtering processes.

Customization Options

- Alloy Composition: Custom ratios of Nickel, Iron, and Cobalt to meet application-specific needs.

- Target Size and Shape: Tailored to fit specific sputtering systems and deposition requirements.

- Bonding Services: Backing plate bonding for effective thermal management and enhanced deposition.

- Purity Levels: Options for ultra-high purity for critical applications in semiconductor and data storage industries.

For more information on Nickel Iron Cobalt (NiFeCo) sputtering targets and to discuss your unique requirements, feel free to contact us. We offer high-quality, customized sputtering targets tailored to your thin-film deposition needs.