NiTi (Nickel Titanium) Alloy Target

- Shape Memory Effect: NiTi alloys can return to their original shape after deformation when exposed to a certain temperature, making them highly valuable in applications requiring memory or actuation.

- Superelasticity: NiTi alloys exhibit significant elastic deformation, which allows them to absorb and release mechanical stress, ideal for flexible and resilient components.

- Corrosion Resistance: NiTi has excellent resistance to corrosion, making it suitable for biomedical devices and components exposed to harsh environments.

- Biocompatibility: NiTi alloys are biocompatible, making them safe for use in medical applications, particularly in implantable devices.

- Wear Resistance: The hardness and durability of NiTi alloys provide long-lasting wear resistance in protective thin films.

- Thermal Stability: NiTi films maintain their unique mechanical properties even at varying temperatures, ensuring consistent performance in diverse conditions.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Nickel Titanium |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

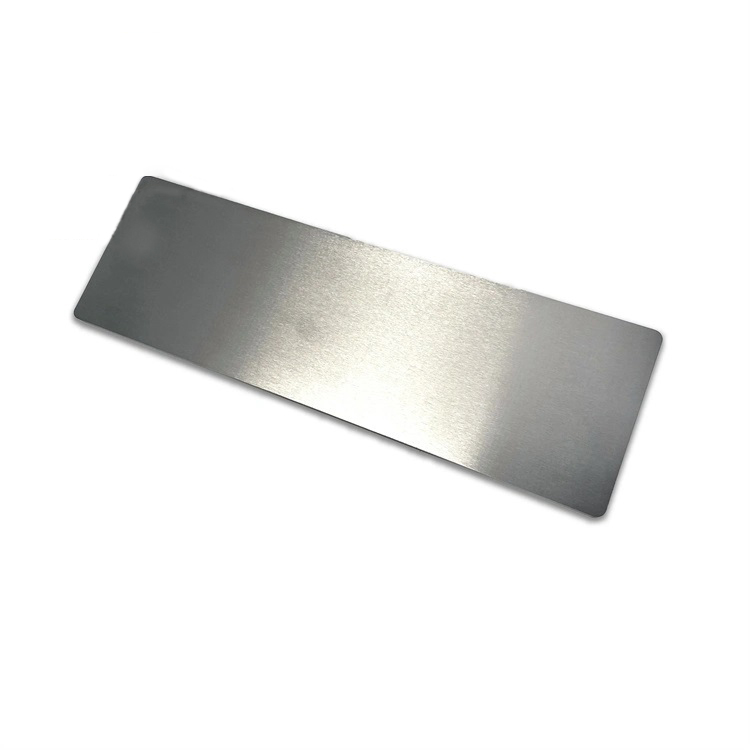

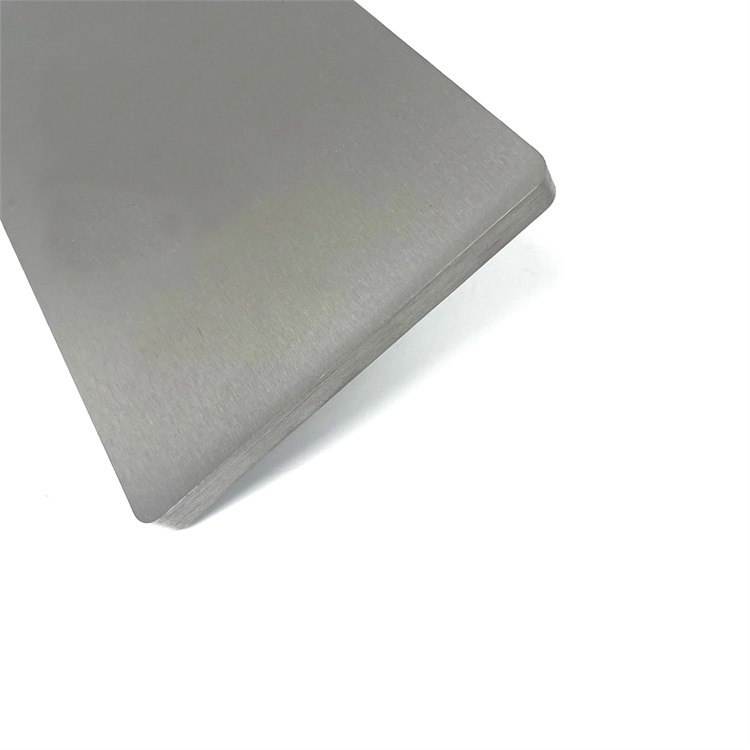

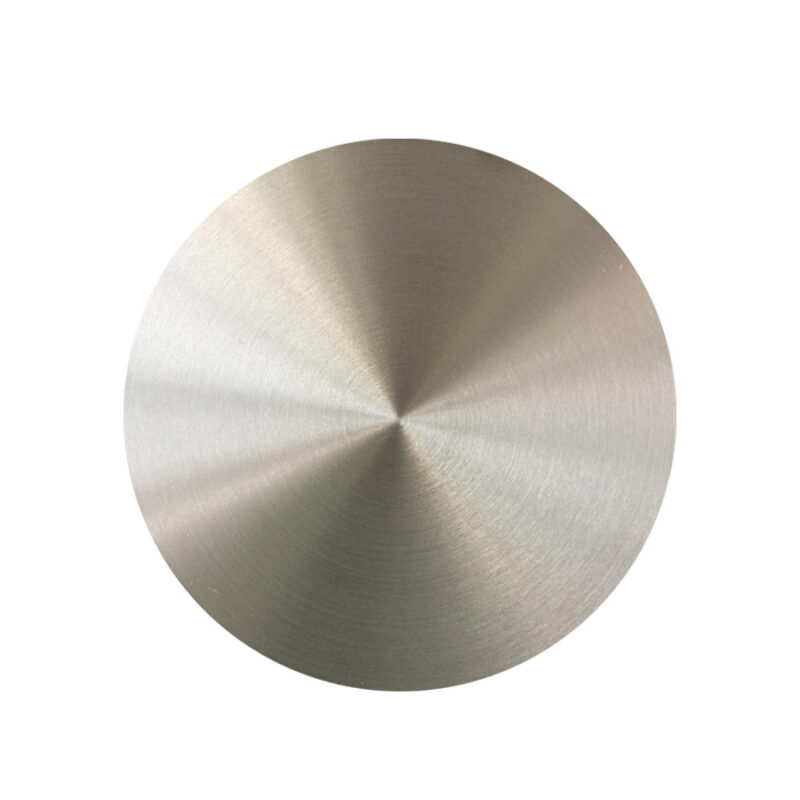

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Nickel-Titanium (NiTi) alloy sputtering targets, also known as Nitinol, are highly valued for their unique properties such as shape memory effect, superelasticity, and excellent corrosion resistance. These properties make NiTi alloys a popular choice for thin-film deposition in applications requiring durability, flexibility, and precise performance.

Key Applications:

- Medical Devices: NiTi alloy is extensively used in the medical field for stents, guidewires, and other devices that benefit from the alloy’s shape memory and superelastic properties. NiTi thin films are ideal for coating medical components that need flexibility and biocompatibility.

- Aerospace & Defense: NiTi sputtering targets are used for thin-film applications in aerospace and defense industries, particularly for components that require resilience to deformation, stress, and temperature changes.

- Microelectromechanical Systems (MEMS): NiTi is employed in MEMS devices, where its shape memory effect and superelastic properties are critical for creating actuators and sensors with precise control and reliability.

- Consumer Electronics: In consumer electronics, NiTi thin films are used for durable, flexible components such as connectors, springs, and switches, where long-term performance and fatigue resistance are essential.

- Wear-Resistant Coatings: NiTi thin films offer excellent wear resistance, making them suitable for protective coatings in high-wear environments like machinery and tools.

Features of NiTi Alloy Sputtering Targets:

- Shape Memory Effect: NiTi alloys can return to their original shape after deformation when exposed to a certain temperature, making them highly valuable in applications requiring memory or actuation.

- Superelasticity: NiTi alloys exhibit significant elastic deformation, which allows them to absorb and release mechanical stress, ideal for flexible and resilient components.

- Corrosion Resistance: NiTi has excellent resistance to corrosion, making it suitable for biomedical devices and components exposed to harsh environments.

- Biocompatibility: NiTi alloys are biocompatible, making them safe for use in medical applications, particularly in implantable devices.

- Wear Resistance: The hardness and durability of NiTi alloys provide long-lasting wear resistance in protective thin films.

- Thermal Stability: NiTi films maintain their unique mechanical properties even at varying temperatures, ensuring consistent performance in diverse conditions.

Customization Options:

- Dimensions: NiTi sputtering targets can be manufactured in various sizes and shapes, including discs, plates, and custom geometries, to meet specific thin-film deposition system requirements.

- Purity Levels: High-purity NiTi alloy sputtering targets (up to 99.99%) are available for advanced applications in medical devices, electronics, and aerospace.

- Nickel-to-Titanium Ratio: The Ni-to-Ti ratio can be customized to adjust the mechanical properties and performance of the thin film, depending on application needs.

NiTi alloy sputtering targets from Tinsan Materials provide shape memory, superelasticity, and corrosion resistance for medical devices, MEMS, aerospace, and wear-resistant coatings. Custom sizes and compositions available for advanced thin-film deposition.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.