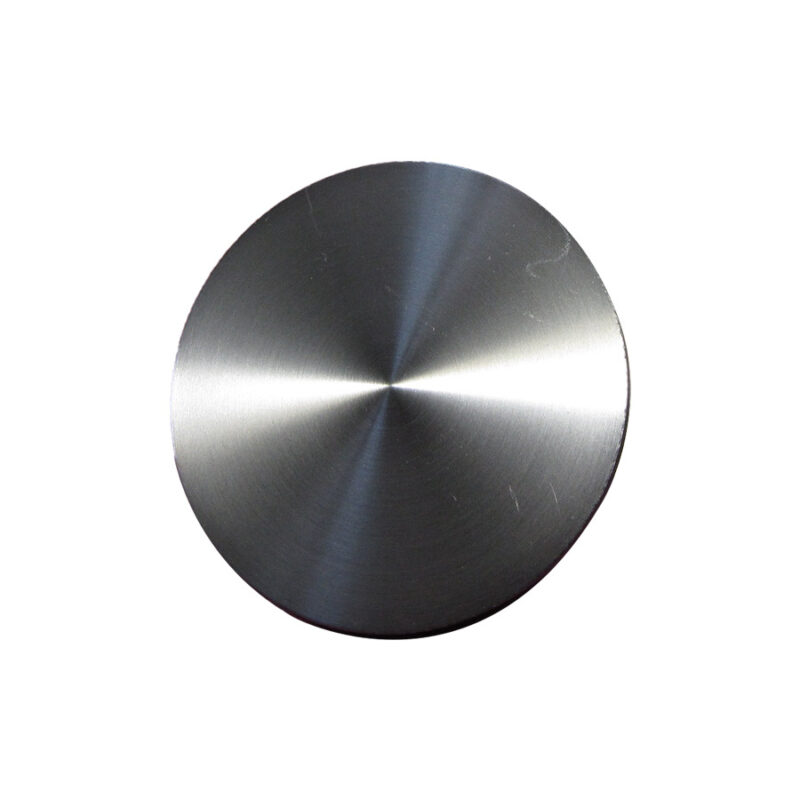

PZT (Lead Zirconate Titanate or Pb(Zr,Ti)O3) Sputtering Targets

- High Piezoelectric Coefficient: Enables efficient conversion of mechanical energy to electrical energy and vice versa.

- Stable Dielectric Properties: Ensures reliable performance in high-frequency applications.

- Customizable Compositions: Tailored Zr/Ti ratios to meet specific functional requirements.

- High Purity and Uniformity: Ensures consistent film deposition with minimal defects.

- Versatile Deposition: Compatible with RF and DC magnetron sputtering systems.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Lead Zirconate Titanate (Pb(Zr,Ti)O₃ or PZT) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Lead Zirconate Titanate (Pb(Zr,Ti)O₃ or PZT) sputtering targets are advanced ceramic materials widely utilized in thin-film deposition processes for piezoelectric and ferroelectric applications. PZT offers exceptional dielectric and piezoelectric properties, making it a key material in sensors, actuators, transducers, and memory devices.

Key Applications

- Piezoelectric Devices: Utilized in sensors, actuators, and ultrasonic transducers.

- Ferroelectric Thin Films: Ideal for non-volatile memory applications such as FRAM.

- Microelectromechanical Systems (MEMS): Found in devices requiring high precision and responsiveness.

- Energy Harvesting: Used in piezoelectric energy generators.

- Optoelectronic Applications: Suitable for integrated optical devices and modulators.

Features and Benefits

- High Piezoelectric Coefficient: Enables efficient conversion of mechanical energy to electrical energy and vice versa.

- Stable Dielectric Properties: Ensures reliable performance in high-frequency applications.

- Customizable Compositions: Tailored Zr/Ti ratios to meet specific functional requirements.

- High Purity and Uniformity: Ensures consistent film deposition with minimal defects.

- Versatile Deposition: Compatible with RF and DC magnetron sputtering systems.

Specifications

- Purity: ≥ 99.9% for superior thin-film quality.

- Density: Optimized for efficient sputtering and uniform deposition.

- Dimensions: Custom shapes and sizes available to suit various deposition systems.

- Formulation: Tunable Zr/Ti ratios for targeted piezoelectric and dielectric properties.

- Surface Finish: Smooth, polished surface for precise film deposition.

Customization Options

- Zr/Ti Ratio Adjustment: Tailored compositions to optimize performance for specific applications.

- Size and Shape Variability: Custom dimensions to match sputtering equipment.

- Bonding Services: Backing plate options for enhanced thermal management.

- Special Packaging: Secure and contamination-free packaging for safe transport and storage.

Looking for high-quality Lead Zirconate Titanate (PZT) sputtering targets? Contact us for customizable solutions, expert advice, and dependable delivery to support your thin-film deposition needs.