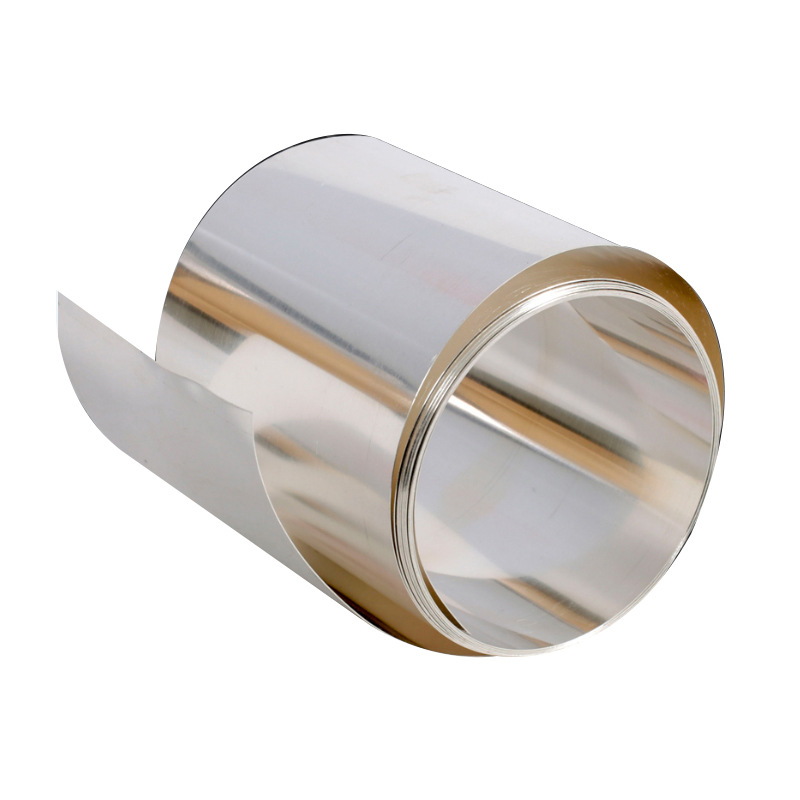

Re Rhenium Foil

- High Melting Point: Rhenium has an extremely high melting point of 3180°C, making it ideal for use in environments with intense heat.

- Excellent Corrosion and Oxidation Resistance: Rhenium foil shows outstanding resistance to oxidation and corrosion, even at high temperatures.

- High Density and Strength: Known for its superior density and strength, rhenium foil maintains structural integrity under heavy loads and extreme temperatures.

- Thermal and Electrical Conductivity: Rhenium exhibits excellent thermal and electrical conductivity, making it suitable for high-performance applications in electronics.

- Malleability and Ductility: Despite its strength, rhenium foil can be easily processed, providing flexibility in various manufacturing processes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Rhenium foil is a high-performance material known for its exceptional properties in high-temperature, high-stress environments. With remarkable strength, resistance to corrosion, and excellent electrical conductivity, rhenium foil is used in aerospace, electronics, and other critical industries where reliability under extreme conditions is required. Tinsan Materials offers high-quality rhenium foil customized to meet specific requirements, ensuring superior performance in various demanding applications.

Properties of Rhenium Foil

- High Melting Point: Rhenium has an extremely high melting point of 3180°C, making it ideal for use in environments with intense heat.

- Excellent Corrosion and Oxidation Resistance: Rhenium foil shows outstanding resistance to oxidation and corrosion, even at high temperatures.

- High Density and Strength: Known for its superior density and strength, rhenium foil maintains structural integrity under heavy loads and extreme temperatures.

- Thermal and Electrical Conductivity: Rhenium exhibits excellent thermal and electrical conductivity, making it suitable for high-performance applications in electronics.

- Malleability and Ductility: Despite its strength, rhenium foil can be easily processed, providing flexibility in various manufacturing processes.

Advantages of Rhenium Foil

- High-Temperature Performance: Rhenium foil is an excellent choice for high-temperature applications due to its high melting point and stability under thermal stress.

- Superior Durability: Resistant to wear, oxidation, and corrosion, rhenium foil offers long-lasting durability in harsh environments.

- Precision Manufacturing: Can be produced to extremely thin and precise dimensions, ensuring high-quality and consistent performance.

- Enhanced Performance in Aerospace and Electronics: Its unique properties make it ideal for critical components in aerospace and electronic systems that require exceptional durability and reliability.

- Versatility in Use: Suitable for a variety of applications across industries, from aerospace to energy and electronics.

Applications of Rhenium Foil

- Aerospace and Aviation: Used in turbine blades, engine components, and other high-stress areas that require materials to withstand extreme temperatures and pressures.

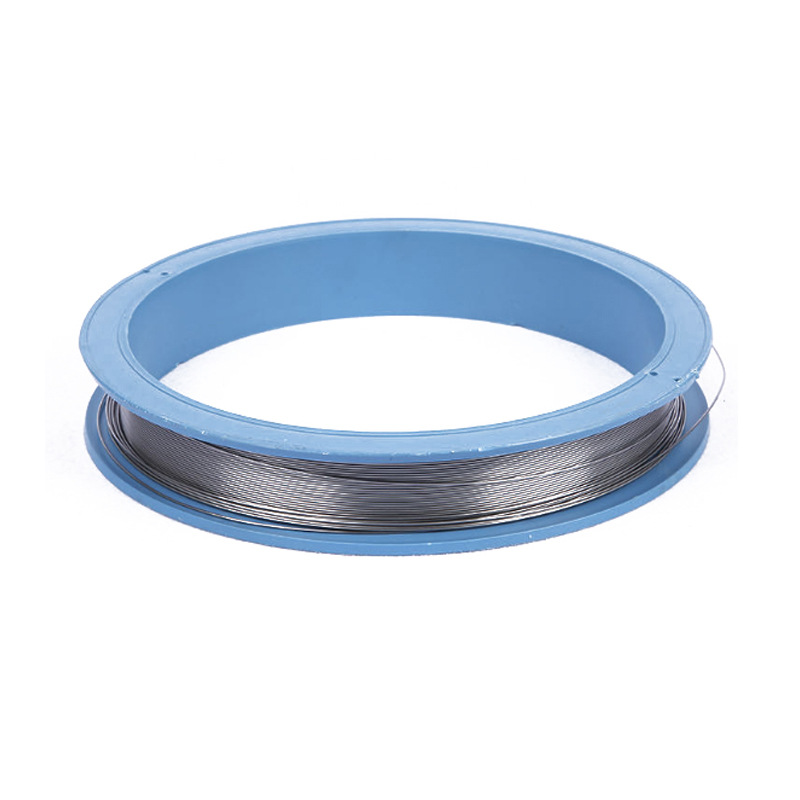

- Electronics and Semiconductors: Rhenium foil is used in high-performance electrical contacts, thin-film deposition, and components where stability and conductivity are crucial.

- Catalysis: Rhenium foil plays an essential role as a catalyst in chemical reactions, particularly in the production of high-performance fuels and chemicals.

- High-Temperature Furnaces: Due to its ability to withstand high heat, rhenium foil is commonly used in high-temperature furnaces, providing reliable and consistent performance.

- Medical Equipment: Rhenium foil is utilized in medical devices, especially in environments requiring precision and high heat resistance.

- Research and Development: Used in various high-tech research applications, especially where extreme conditions are involved.

At Tinsan Materials, we provide custom rhenium foil tailored to meet the specific demands of your industry. Whether you need ultra-thin foils for electronic applications or thicker foils for aerospace use, our products are designed and manufactured with the highest standards of quality and precision.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.