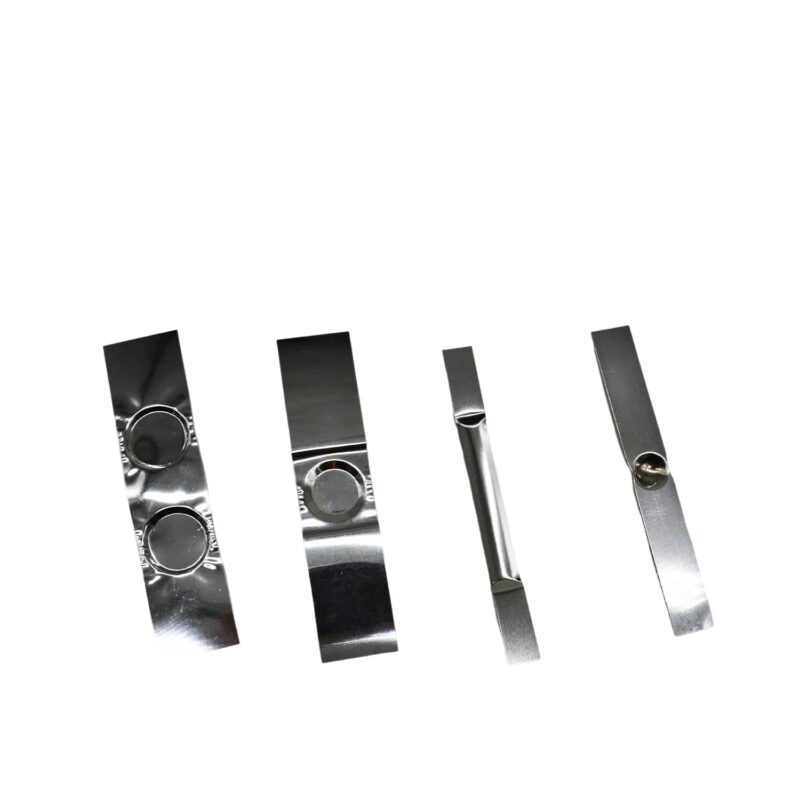

Sc Scandium Foil

- High Strength-to-Weight Ratio: Scandium foil offers excellent mechanical strength relative to its weight, making it a lightweight yet durable material ideal for aerospace and military applications.

- High Melting Point: Scandium has a high melting point of 1,540°C (2,804°F), providing exceptional performance in high-temperature environments.

- Corrosion Resistance: Scandium foil exhibits remarkable resistance to corrosion, especially in acidic and saline environments, making it suitable for challenging environmental conditions.

- Thermal Stability: The material maintains its mechanical properties even at elevated temperatures, ensuring long-term reliability in high-heat applications.

- Non-toxic and Biocompatible: Scandium foil is non-toxic, making it safe for medical and other applications where human exposure may occur. Its biocompatibility is also an asset for certain implantable medical devices.

- Electrical Conductivity: Although not as conductive as copper, scandium foil still offers good electrical conductivity, making it suitable for various electronic applications.

- Lightweight: Scandium is a relatively light metal, which helps reduce the weight of components and systems, particularly in aerospace and defense applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Scandium foil is a highly specialized material known for its unique combination of strength, lightness, and excellent performance in extreme conditions. As a rare earth metal, scandium is used in various high-performance applications where its distinctive properties provide a competitive edge. It is particularly valued in aerospace, electronics, and high-tech industries.

Properties of Scandium Foil

- High Strength-to-Weight Ratio: Scandium foil offers excellent mechanical strength relative to its weight, making it a lightweight yet durable material ideal for aerospace and military applications.

- High Melting Point: Scandium has a high melting point of 1,540°C (2,804°F), providing exceptional performance in high-temperature environments.

- Corrosion Resistance: Scandium foil exhibits remarkable resistance to corrosion, especially in acidic and saline environments, making it suitable for challenging environmental conditions.

- Thermal Stability: The material maintains its mechanical properties even at elevated temperatures, ensuring long-term reliability in high-heat applications.

- Non-toxic and Biocompatible: Scandium foil is non-toxic, making it safe for medical and other applications where human exposure may occur. Its biocompatibility is also an asset for certain implantable medical devices.

- Electrical Conductivity: Although not as conductive as copper, scandium foil still offers good electrical conductivity, making it suitable for various electronic applications.

- Lightweight: Scandium is a relatively light metal, which helps reduce the weight of components and systems, particularly in aerospace and defense applications.

Advantages of Scandium Foil

- Enhanced Material Properties: When used as an alloying agent, scandium significantly enhances the properties of other metals, improving strength, corrosion resistance, and thermal stability.

- Aerospace and Defense Applications: Scandium is a critical component in the development of lightweight, high-strength materials for aerospace and defense, reducing the overall weight of aircraft and military equipment while maintaining structural integrity.

- Electronics: Scandium foil is used in high-performance electronic components that require stable, lightweight materials with high heat resistance and electrical conductivity.

- Corrosion Resistance: Its resistance to corrosion allows for longevity in marine environments and other aggressive settings, extending the life of devices and components.

- Biocompatibility for Medical Applications: Scandium’s non-toxic and biocompatible nature makes it valuable for use in medical devices, such as implants, where material safety is paramount.

Applications of Scandium Foil

- Aerospace Industry: ①Lightweight Alloys: Scandium is often used to strengthen aluminum alloys, providing enhanced performance in lightweight materials for aerospace applications. ②Aircraft and Satellites: Its strength-to-weight ratio makes scandium foil ideal for components in aircraft, satellites, and other aerospace technology.

- Defense and Military: ①Weapons and Armor: Due to its strength and resistance to high-temperature and corrosive environments, scandium foil is used in the production of military-grade alloys and advanced defense materials. ②Lightweight Armored Vehicles: Scandium-enhanced alloys are used to create lighter, stronger materials for armored vehicles and military equipment.

- Electronics and Semiconductors: High-Performance Components: Scandium foil is used in the manufacture of advanced electronic components, such as high-frequency devices and semiconductors, where thermal stability and conductivity are crucial.

- Hydrogen Storage: Scandium has been explored for use in hydrogen storage systems, offering potential improvements in energy storage and fuel cell technology.

- Medical Devices: ①Implants: Due to its non-toxicity and biocompatibility, scandium foil is used in medical implants and devices, offering reliable performance in the human body. ②Medical Instruments: Scandium is used in various precision medical instruments, benefiting from its resistance to corrosion and mechanical strength.

- Sports Equipment: Scandium alloys are used in the production of high-performance sports equipment, such as bicycles, baseball bats, and golf clubs, where lightweight yet strong materials are required.

- Battery Technology: Scandium has also shown promise in enhancing the performance of lithium-ion batteries, providing a boost to energy density and overall efficiency.

At Tinsan Materials, we specialize in the production of custom-sized scandium foil. We can tailor the material to meet specific requirements, including thickness, width, and purity levels. Our advanced manufacturing processes ensure that our scandium foil maintains superior quality and reliability for use in demanding applications across various industries.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.