Si3N4 (Silicon Nitride) Pellets Granules Evaporation Materials

- High purity (≥99.9%).

- Outstanding thermal and mechanical stability.

- Uniform pellet size for precise deposition.

- Customizable sizes and specifications.

- Superior resistance to oxidation, corrosion, and wear.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Silicon Nitride (Si₃N₄) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Silicon Nitride (Si₃N₄) Pellets are high-purity materials widely used in advanced industries such as semiconductors, thin-film deposition, and ceramic manufacturing. Renowned for their excellent thermal stability, chemical resistance, and mechanical strength, Si₃N₄ Pellets are ideal for applications in wear-resistant coatings, high-temperature components, and electronic devices. Their consistent quality and high purity make them suitable for both industrial processes and scientific research.

Key Features

- High purity (≥99.9%).

- Outstanding thermal and mechanical stability.

- Uniform pellet size for precise deposition.

- Customizable sizes and specifications.

- Superior resistance to oxidation, corrosion, and wear.

Technical Specifications

① Chemical Composition

- Silicon Nitride (Si₃N₄) Content: ≥99.9%.

- Trace Impurities: Available upon request.

② Physical Properties

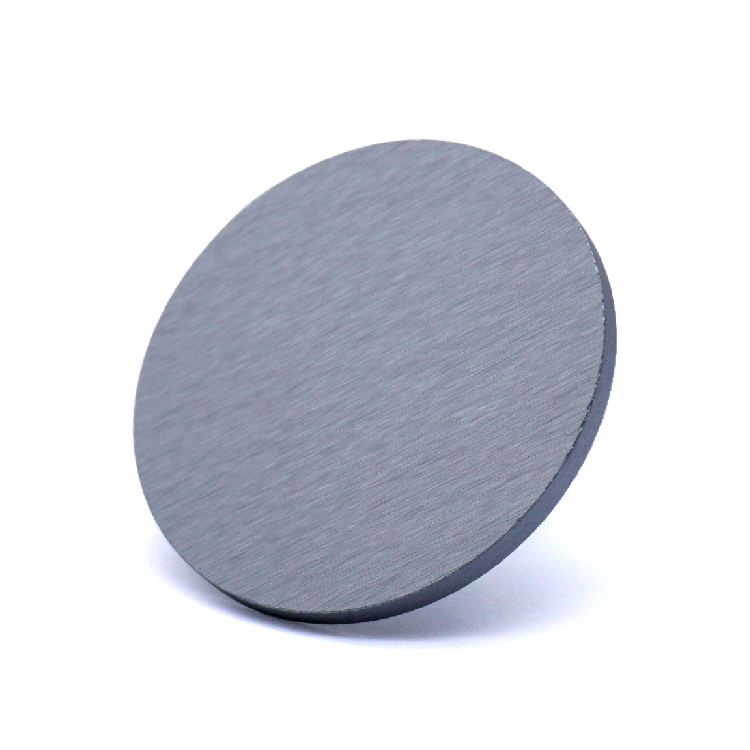

- Appearance: Light gray pellets.

- Density: ~3.2 g/cm³.

- Melting Point: Decomposes above 1900°C in inert atmosphere.

③ Pellet Size

- Standard Sizes: 1-3 mm, 3-5 mm.

- Custom sizes available to meet specific deposition requirements.

Applications

- Thin-Film Deposition: Ideal for PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) processes to create wear-resistant and insulating coatings.

- Ceramics Manufacturing: Used in producing high-performance ceramics for engine parts, cutting tools, and thermal insulation.

- Semiconductor Industry: Applied in manufacturing electronic components and insulating layers for high-temperature applications.

- Aerospace and Automotive: Perfect for wear-resistant components like bearings, turbine blades, and engine parts operating under extreme conditions.

- Research and Development: Widely used in academic and industrial research for developing advanced materials.

Product Advantages

- High Purity: Ensures reliable performance in critical applications.

- Exceptional Durability: High resistance to thermal shock, wear, and chemical attack.

- Custom Solutions: Tailored sizes and specifications for unique application needs.

- Uniform Quality: Consistent pellet size for repeatable deposition results.

Packaging and Storage

① Packaging

- Sealed in moisture-proof aluminum foil bags or airtight containers.

- Custom packaging available upon request.

② Storage

- Store in a dry, cool environment to avoid contamination.

- Ensure containers are sealed tightly to maintain product integrity over time.

Quality Certifications

- ISO 9001 Certified Quality Management System.

- RoHS Compliance.

- Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS) provided upon request.

For additional information or to request a quote, please contact us. Our team of experts is available to provide tailored solutions for your application needs.