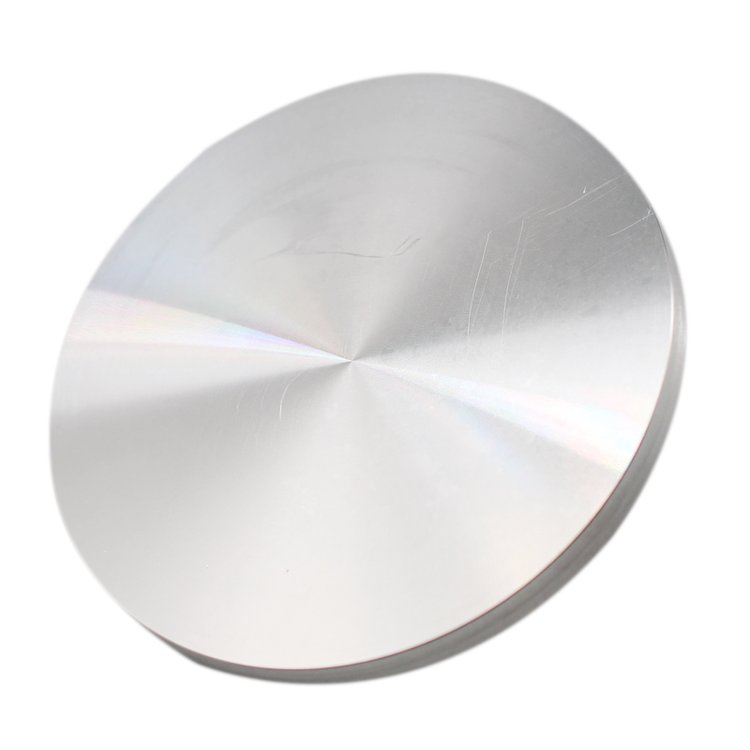

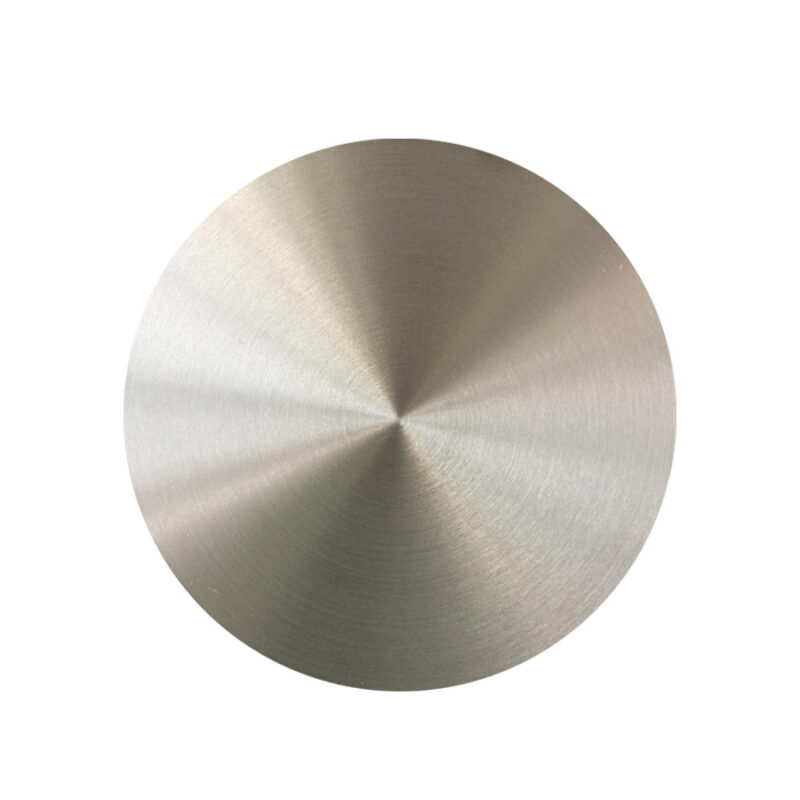

Sn Tin Sputtering Targets

- High Purity: Typically available in purities of 99.9% (3N) to 99.9999% (6N), ensuring high-quality deposition with minimal impurities.

- Good Conductivity: Tin is an excellent conductor of electricity, making it ideal for electronic and semiconductor applications.

- Corrosion Resistance: Exhibits resistance to oxidation and corrosion, ensuring durable and stable coatings.

- Low Melting Point: Tin has a relatively low melting point (232°C), facilitating efficient sputtering processes.

- Versatility: Suitable for creating uniform films in a range of applications, including electronic, decorative, and optical coatings.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Tin (Sn) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tin (Sn) sputtering targets are high-purity metallic materials used in physical vapor deposition (PVD) processes, such as sputtering, to create thin films and coatings. Tin is a soft, malleable, silvery-white metal with excellent corrosion resistance and good electrical conductivity, making it a valuable material for various industries, including electronics, optics, and protective coatings.

Key Features:

- High Purity: Typically available in purities of 99.9% (3N) to 99.9999% (6N), ensuring high-quality deposition with minimal impurities.

- Good Conductivity: Tin is an excellent conductor of electricity, making it ideal for electronic and semiconductor applications.

- Corrosion Resistance: Exhibits resistance to oxidation and corrosion, ensuring durable and stable coatings.

- Low Melting Point: Tin has a relatively low melting point (232°C), facilitating efficient sputtering processes.

- Versatility: Suitable for creating uniform films in a range of applications, including electronic, decorative, and optical coatings.

Specifications:

- Material Composition: Tin (Sn)

- Purity Levels: 99.9% (3N), 99.99% (4N), 99.999% (5N), 99.9999% (6N)

- Shape:

- Disc

- Plate

- Cylinder

- Dimensions: Customizable based on deposition equipment requirements

- Diameter Range: 1″ to 12″ or as per specifications

- Thickness: From 0.1mm to several millimeters

- Density: 7.31 g/cm³

- Surface Finish: Fine machined, polished

Applications:

- Electronics: ①Used in the deposition of conductive layers in PCBs, semiconductors, and microelectronics. ②Tin coatings are used for solderability in electronic components.

- Optics: For creating reflective and protective coatings on glass and optical devices.

- Decorative Coatings: Applied to decorative items for a shiny, corrosion-resistant finish.

- Protective Coatings: Tin layers are used as barriers to protect underlying materials from corrosion and wear.

- Energy Applications: Tin coatings are used in photovoltaic cells and energy storage devices.

- Tribological Coatings: Thin tin films can reduce friction and wear in mechanical components.

Advantages of Tin Sputtering Targets:

- Uniform Thin Films: Produces high-quality, defect-free coatings with excellent adhesion.

- Recyclable Material: Tin sputtering targets can often be recycled for cost efficiency and sustainability.

- Customizable Specifications: Available in various shapes, sizes, and purities to meet specific industrial or research needs.

Storage and Handling:

- Storage: Store in a dry, clean environment to prevent oxidation.

- Handling: Avoid exposure to moisture and contaminants to maintain purity.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.