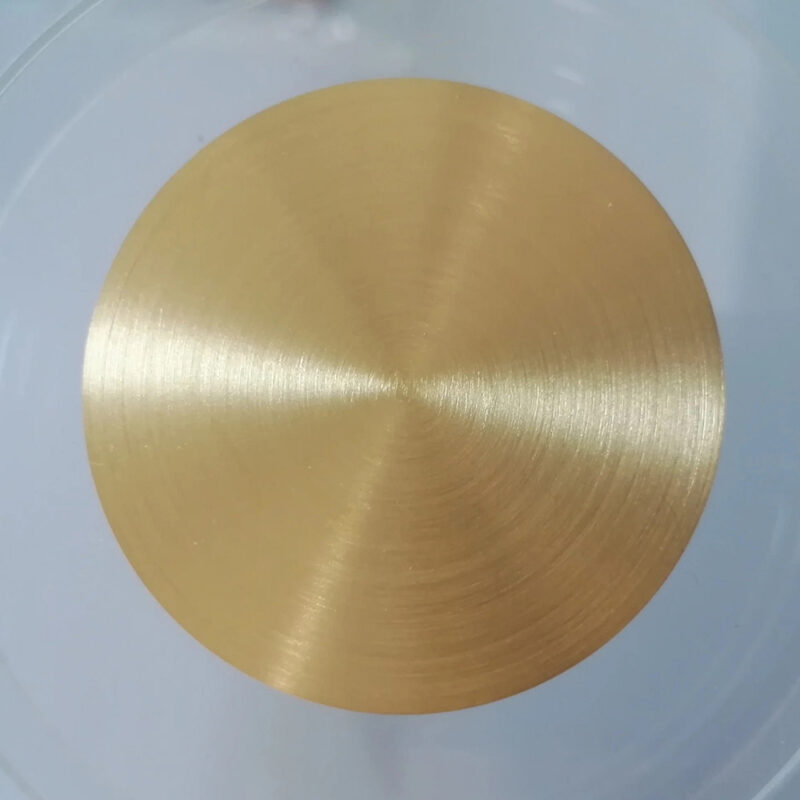

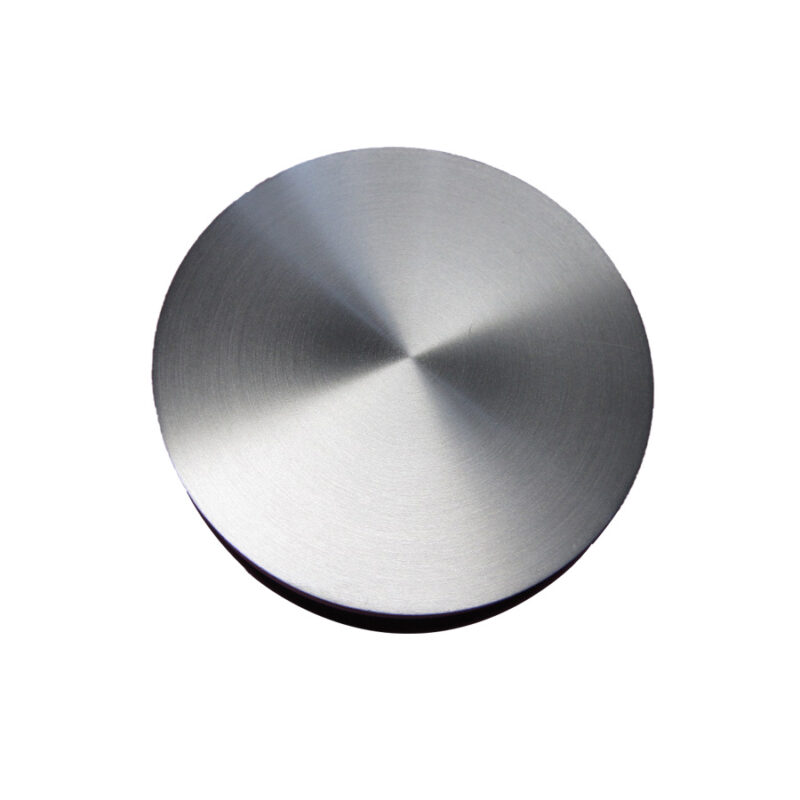

Ta Tantalum Sputtering Targets

- High Purity: Ensures contamination-free thin films for critical applications.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Melting Point: Stable under extreme thermal conditions.

- Superior Electrical Conductivity: Suitable for advanced electronic devices.

- Customizable Options: Adaptable to specific design and operational requirements.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Tantalum (Ta) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tantalum (Ta) sputtering targets are widely used in advanced thin-film deposition applications due to their exceptional thermal, chemical, and mechanical properties. Known for high corrosion resistance, superior conductivity, and excellent compatibility with various substrates, tantalum is an ideal material for semiconductor, aerospace, and electronic industries. These targets ensure uniform deposition, making them a preferred choice for producing reliable thin films.

Key Applications

- Semiconductors: Ideal for diffusion barriers and interconnects in integrated circuits and chips.

- Aerospace: Protective coatings for high-performance components.

- Medical Devices: Biocompatible coatings for implants and surgical instruments.

- Optoelectronics: Thin films for optical reflectors and components.

- Energy Storage: Used in capacitors and battery electrodes.

Features and Benefits

- High Purity: Ensures contamination-free thin films for critical applications.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Melting Point: Stable under extreme thermal conditions.

- Superior Electrical Conductivity: Suitable for advanced electronic devices.

- Customizable Options: Adaptable to specific design and operational requirements.

Specifications

- Purity: ≥ 99.9% (customizable for specific applications).

- Density: 16.65 g/cm³ for high sputtering efficiency.

- Form: Discs, plates, and custom shapes.

- Dimensions: Wide range of sizes to fit various sputtering systems.

- Surface Finish: Polished to industry standards for optimal performance.

Customization Options

- Dimensions and Shapes: Tailored to meet unique deposition system requirements.

- Alloy Options: Available as tantalum alloys to enhance specific properties.

- Bonding Services: Backing plates and bonding options for improved thermal management.

- Packaging: Custom protective packaging to ensure safe handling and transport.

Explore our high-quality tantalum sputtering targets designed to meet diverse industry needs. Contact our experts for technical guidance, customization services, and competitive pricing. We ensure precise solutions to elevate your thin-film deposition projects.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.