TaC (Tantalum Carbide) Sputtering Target

- Extreme Hardness: TaC coatings provide excellent hardness, making them ideal for cutting tools, wear-resistant coatings, and surfaces exposed to high friction.

- High Melting Point: With a melting point exceeding 3880°C, TaC is one of the most heat-resistant materials, suitable for high-temperature applications in aerospace and industrial processes.

- Corrosion Resistance: TaC films offer robust resistance to chemicals, making them ideal for protective coatings in chemically aggressive environments.

- Electrical Conductivity: TaC has good electrical conductivity, which is advantageous in certain electronic and semiconductor applications.

- Oxidation Resistance: The oxidation resistance of TaC enhances its performance in environments where exposure to high temperatures and reactive gases is common.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | TaC |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

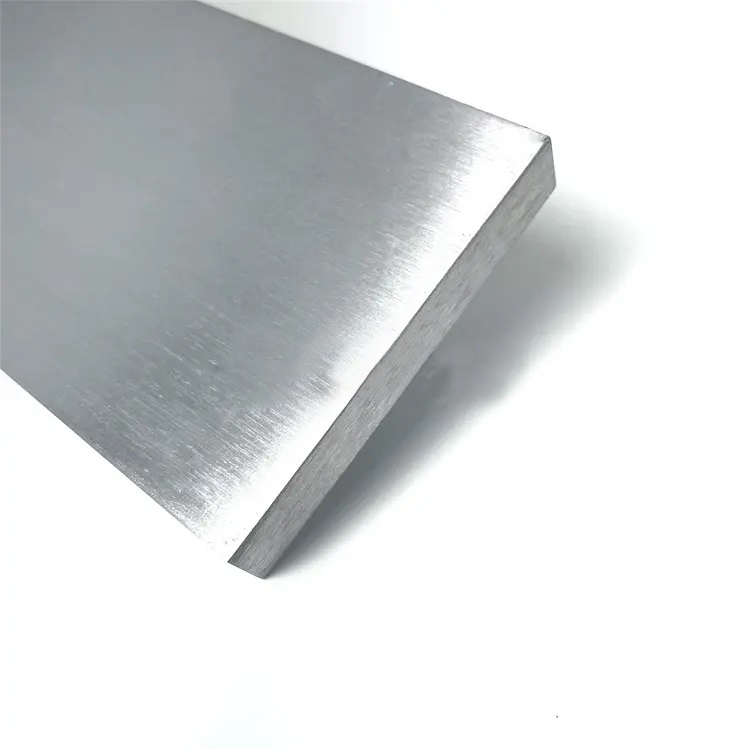

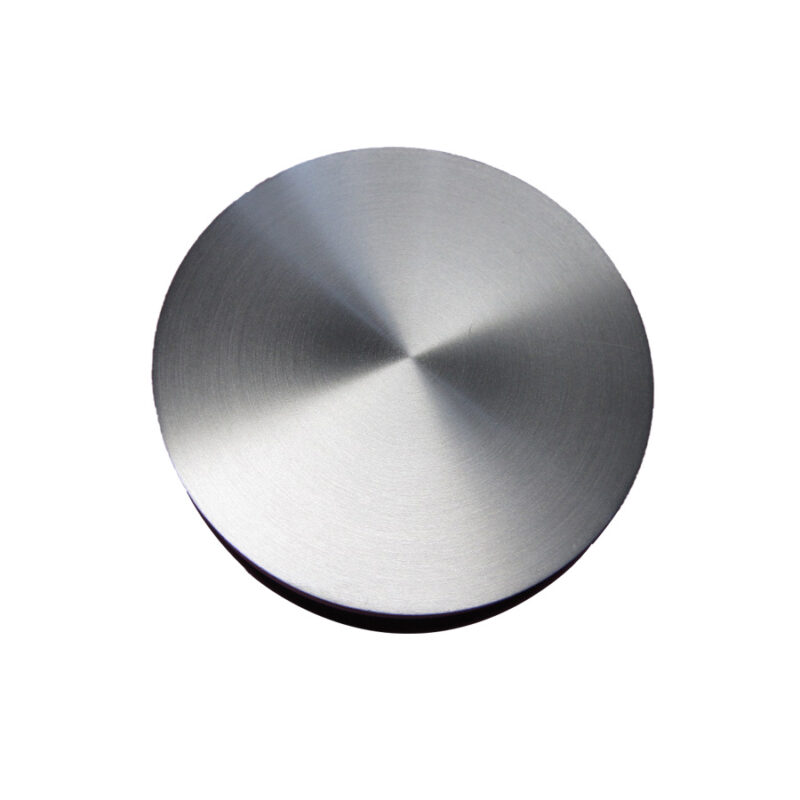

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tantalum Carbide (TaC) sputtering targets are used to deposit thin films with exceptional hardness, high melting points, and chemical inertness. TaC is known for its remarkable thermal stability and resistance to wear, corrosion, and oxidation, making it a preferred material in high-performance applications such as aerospace, cutting tools, and electronic components.

Key Applications:

- Hard Coatings: TaC thin films are applied to cutting tools, wear parts, and components exposed to extreme conditions to improve hardness, wear resistance, and durability.

- Protective Coatings: TaC coatings are used in environments where resistance to corrosion, oxidation, and high temperatures is crucial, including aerospace, automotive, and industrial machinery.

- Aerospace and High-Temperature Applications: TaC’s high melting point and thermal stability make it suitable for aerospace components, particularly those exposed to extreme temperatures.

- Semiconductor Industry: TaC films are utilized in semiconductor and microelectronics applications, where its electrical conductivity and thermal properties are valuable for specific processes.

- Optical Coatings: TaC thin films are sometimes used in optical devices, contributing to durability and resistance to wear in lenses and mirrors.

Features of TaC Sputtering Targets:

- Extreme Hardness: TaC coatings provide excellent hardness, making them ideal for cutting tools, wear-resistant coatings, and surfaces exposed to high friction.

- High Melting Point: With a melting point exceeding 3880°C, TaC is one of the most heat-resistant materials, suitable for high-temperature applications in aerospace and industrial processes.

- Corrosion Resistance: TaC films offer robust resistance to chemicals, making them ideal for protective coatings in chemically aggressive environments.

- Electrical Conductivity: TaC has good electrical conductivity, which is advantageous in certain electronic and semiconductor applications.

- Oxidation Resistance: The oxidation resistance of TaC enhances its performance in environments where exposure to high temperatures and reactive gases is common.

Customization Options:

- Target Sizes: TaC sputtering targets are available in a range of shapes and sizes, including round, rectangular, and custom geometries, suitable for different sputtering systems.

- Purity Levels: High-purity TaC targets (up to 99.99%) ensure superior film quality and performance in critical applications.

- Bonding Services: TaC targets can be bonded to backing plates to improve thermal conductivity during sputtering and reduce the risk of target cracking.

TaC (Tantalum Carbide) sputtering targets from Tinsan Materials offer extreme hardness, high thermal stability, and corrosion resistance for thin-film coatings. Ideal for aerospace, hard coatings, and semiconductor applications, TaC targets are customizable in size and purity to meet demanding performance needs.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.