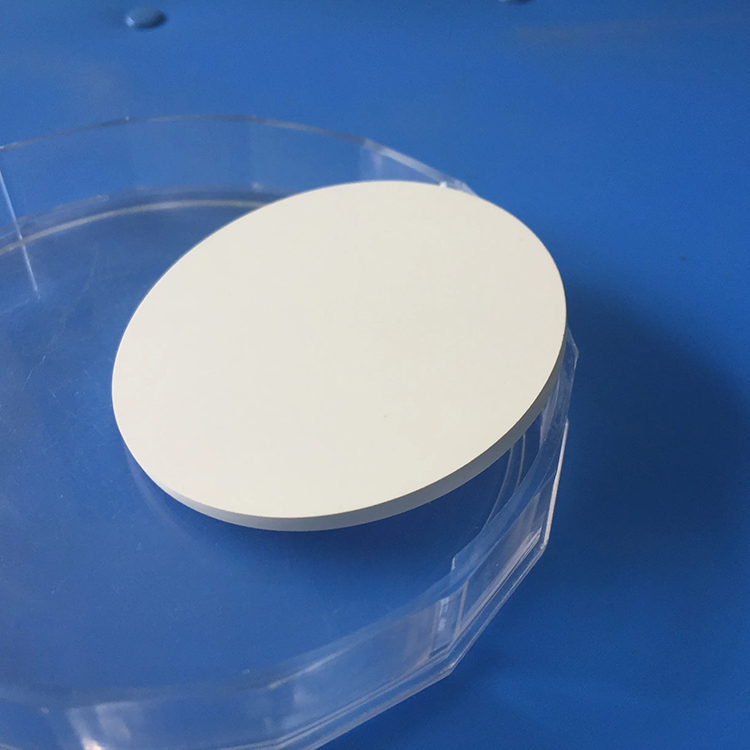

Ti Titanium Foil

- High Strength-to-Weight Ratio: Titanium foil is known for its excellent strength-to-weight ratio, making it a lightweight yet durable material. This property is especially valuable in industries like aerospace, where minimizing weight while maintaining structural integrity is crucial.

- Corrosion Resistance: One of the standout features of titanium is its exceptional resistance to corrosion. It forms a stable oxide layer on its surface, protecting it from environmental factors such as water, air, and chemicals. This makes titanium foil ideal for use in harsh or corrosive environments.

- High-Temperature Resistance: Titanium foil can withstand high temperatures without compromising its mechanical properties. It remains strong and stable even at elevated temperatures, which is why it is used in high-performance applications like jet engines and chemical reactors.

- Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and compatible with the human body. This makes titanium foil a popular choice for medical implants and devices, as it does not cause adverse reactions in the body.

- Excellent Fatigue Resistance: Titanium foil has excellent fatigue resistance, making it suitable for applications that require materials to endure repeated stress without failure. This property is critical in aerospace, automotive, and other engineering sectors.

- Non-Magnetic: Titanium is non-magnetic, which makes titanium foil a valuable material in electronic and medical devices where magnetic interference can affect performance.

- Formability and Flexibility: Titanium foil is highly malleable and can be easily formed into various shapes. It can be rolled, stamped, or processed to meet the specific needs of different applications, making it versatile in manufacturing processes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Titanium foil is a thin, lightweight material with excellent strength, corrosion resistance, and high-temperature stability. It is widely used in various industries, including aerospace, medical, chemical processing, and electronics, due to its remarkable properties. Titanium foil offers an ideal balance of strength and weight, making it particularly useful in applications where performance and durability are critical.

Properties of Titanium Foil

- High Strength-to-Weight Ratio: Titanium foil is known for its excellent strength-to-weight ratio, making it a lightweight yet durable material. This property is especially valuable in industries like aerospace, where minimizing weight while maintaining structural integrity is crucial.

- Corrosion Resistance: One of the standout features of titanium is its exceptional resistance to corrosion. It forms a stable oxide layer on its surface, protecting it from environmental factors such as water, air, and chemicals. This makes titanium foil ideal for use in harsh or corrosive environments.

- High-Temperature Resistance: Titanium foil can withstand high temperatures without compromising its mechanical properties. It remains strong and stable even at elevated temperatures, which is why it is used in high-performance applications like jet engines and chemical reactors.

- Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and compatible with the human body. This makes titanium foil a popular choice for medical implants and devices, as it does not cause adverse reactions in the body.

- Excellent Fatigue Resistance: Titanium foil has excellent fatigue resistance, making it suitable for applications that require materials to endure repeated stress without failure. This property is critical in aerospace, automotive, and other engineering sectors.

- Non-Magnetic: Titanium is non-magnetic, which makes titanium foil a valuable material in electronic and medical devices where magnetic interference can affect performance.

- Formability and Flexibility: Titanium foil is highly malleable and can be easily formed into various shapes. It can be rolled, stamped, or processed to meet the specific needs of different applications, making it versatile in manufacturing processes.

Advantages of Titanium Foil

- Durability: Titanium foil is incredibly durable due to its corrosion resistance and high strength. It performs well even in extreme environments, providing longevity and reducing the need for frequent replacements.

- Lightweight: The low density of titanium makes it significantly lighter than many other metals, such as steel or copper, while still maintaining high strength. This makes it ideal for aerospace and automotive applications where reducing weight is important for efficiency and performance.

- Environmental Resistance: Titanium foil’s ability to resist oxidation, corrosion, and wear ensures that it can withstand a wide range of environmental conditions, from seawater to acidic environments, making it suitable for use in chemical processing, marine, and outdoor applications.

- Biocompatibility: As a biocompatible material, titanium foil is widely used in medical implants and devices, including dental implants, pacemakers, and surgical tools, without causing any harmful reactions in the body.

- Cost-Effectiveness: While titanium may be more expensive than some metals, its durability and longevity make it a cost-effective choice over time, especially in industries where failure due to corrosion or fatigue can result in high maintenance costs.

- Versatility in Manufacturing: Titanium foil is easy to work with due to its malleability, which allows it to be shaped into precise forms, such as thin sheets, strips, or discs. This versatility opens up a wide range of applications across industries.

Applications of Titanium Foil

- Aerospace: Titanium foil is commonly used in the aerospace industry for manufacturing components in jet engines, turbine blades, and heat shields. Its strength-to-weight ratio and high-temperature resistance make it an ideal material for reducing weight while maintaining structural integrity in flight-critical applications.

- Medical and Dental: Titanium foil is used in the medical and dental fields for implants, prosthetics, and surgical instruments. Its biocompatibility ensures that it does not cause adverse reactions in the human body, making it perfect for long-term implantation in medical procedures.

- Chemical Processing: Titanium foil is widely used in chemical processing industries for equipment like heat exchangers, reactors, and piping. Its resistance to corrosion by acids and alkalis makes it ideal for handling aggressive chemicals without degradation over time.

- Electronics: In the electronics industry, titanium foil is used in applications such as capacitors, sensors, and semiconductors. Its non-magnetic properties and excellent conductivity make it suitable for a wide range of electronic components.

- Marine: Due to its corrosion resistance, titanium foil is used in marine environments for boat hulls, propellers, and other components exposed to saltwater. Titanium’s ability to withstand the harsh marine environment extends the lifespan of these parts significantly.

- Energy and Power Generation: Titanium foil is used in nuclear reactors and power plants for fuel cladding, due to its high resistance to corrosion and radiation. It also plays a role in geothermal and oil extraction applications, where high strength and resistance to corrosive substances are required.

- Solar Energy: Titanium foil is increasingly being used in solar energy technologies, including solar panels and photovoltaic cells, due to its durability, corrosion resistance, and excellent conductivity.

- Automotive: In the automotive industry, titanium foil is used in high-performance components such as exhaust systems, catalytic converters, and suspension parts, where reducing weight without sacrificing strength is essential.

Customization and Manufacturing of Titanium Foil

Titanium foil can be manufactured to meet specific requirements, including varying thicknesses, widths, and lengths. Custom production ensures that the foil fits precisely into the intended application, whether for aerospace, medical, or industrial use. The foil can be processed using various techniques, such as rolling, stamping, and coating, to meet the precise needs of different industries.

At Tinsan Materials, we offer high-quality titanium foil in a variety of specifications to suit a broad range of applications. Whether you need thin, high-strength titanium foil for aerospace components or biocompatible foil for medical implants, we can supply materials that meet your exact specifications.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.