TiB2 (Titanium Diboride) Sputtering Targets

- Exceptional Hardness: Provides superior durability and wear resistance.

- High Thermal Stability: Performs well under extreme temperatures.

- Electrical Conductivity: Suitable for electronic applications requiring conductive layers.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Purity: Ensures consistent thin-film quality and reliable performance.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Titanium Diboride (TiB₂) |

| Purity | 99.5% – 99.999% / 2N5 3N 3N5 4N 4N5 5N |

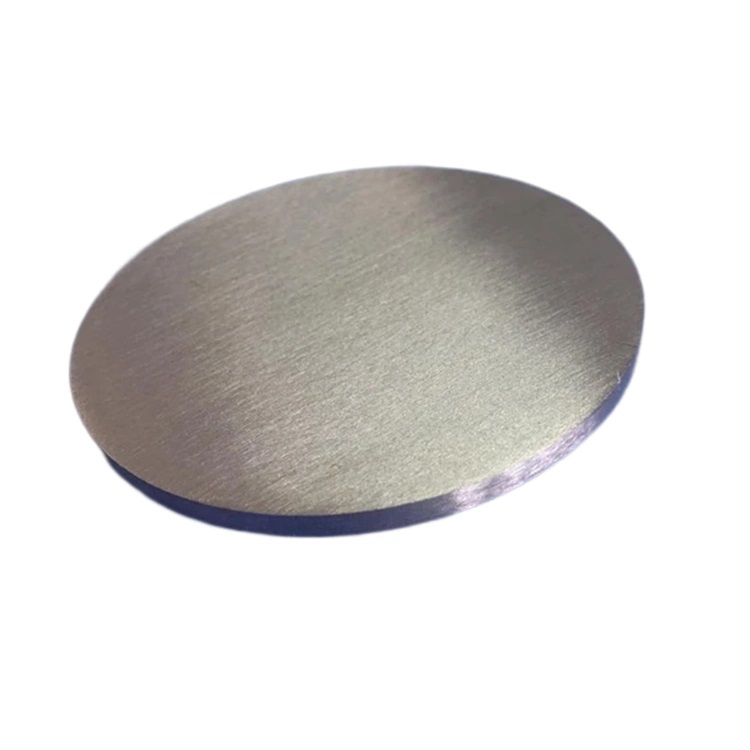

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Titanium Diboride (TiB₂) sputtering targets are highly valued for their exceptional hardness, chemical stability, and superior conductivity. These targets are used in advanced thin-film deposition processes to create coatings with extreme wear resistance, high thermal stability, and excellent electrical properties. TiB₂ is a critical material in industries requiring robust coatings, including aerospace, electronics, and cutting tools.

Key Applications

- Wear-Resistant Coatings: Ideal for tools and machinery exposed to high wear and tear.

- Microelectronics: Used in thin films for semiconductor components due to excellent conductivity.

- Aerospace: Protects components against extreme conditions and oxidation.

- Optical Coatings: Provides scratch-resistant and reflective coatings for optics.

- Decorative Coatings: Creates aesthetic and durable finishes on consumer products.

Features and Benefits

- Exceptional Hardness: Provides superior durability and wear resistance.

- High Thermal Stability: Performs well under extreme temperatures.

- Electrical Conductivity: Suitable for electronic applications requiring conductive layers.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Purity: Ensures consistent thin-film quality and reliable performance.

Specifications

- Purity: ≥ 99.5% for high-quality film deposition.

- Density: Optimized for efficient sputtering processes.

- Shape: Available in discs, plates, and other custom geometries.

- Dimensions: Tailored to fit various sputtering systems.

Customization Options

- Custom Shapes and Sizes: Designed to meet specific equipment and application needs.

- Backing Plates: Provided for enhanced thermal management and mechanical support.

- Tailored Composition: Adjustments for specific film properties or performance requirements.

Reach out to our experts for more information about TiB₂ sputtering targets. We offer comprehensive support, including material selection, customization, and competitive pricing, to meet your thin-film coating needs.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.