TiC (Titanium Carbide) Sputtering Target

- High Hardness: TiC coatings provide excellent hardness, making them suitable for wear-resistant applications like cutting tools and dies.

- Corrosion Resistance: TiC films resist oxidation and corrosion, providing a protective barrier in harsh environments, including high-temperature applications.

- Thermal Stability: TiC has high thermal stability, making it ideal for coatings in high-temperature operations such as aerospace and automotive components.

- Electrical Conductivity: TiC exhibits good electrical conductivity, making it suitable for certain electronic and semiconductor applications where conductivity is critical.

- Chemical Resistance: TiC coatings offer chemical resistance, providing protective layers against corrosive agents and harsh chemicals.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | TiC |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

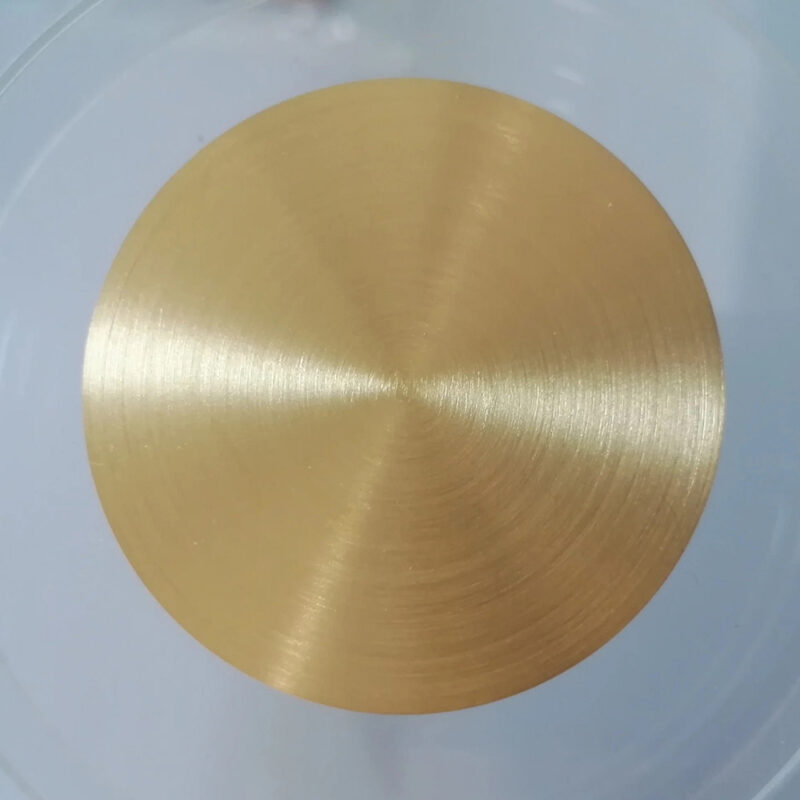

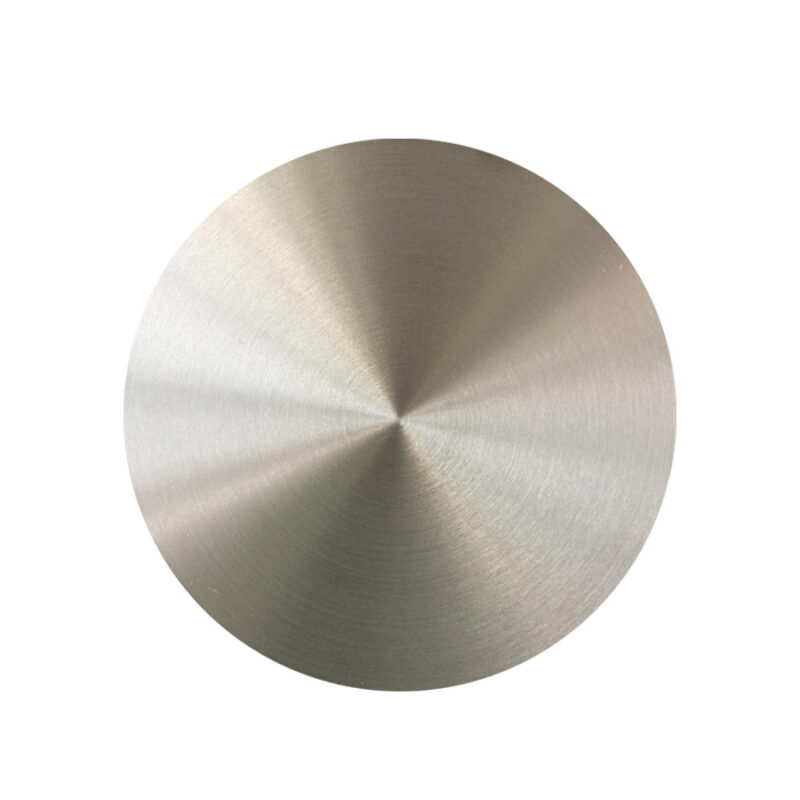

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Titanium Carbide (TiC) sputtering targets are used for the deposition of thin films in various advanced applications requiring hardness, wear resistance, and electrical conductivity. TiC is a ceramic material that exhibits high melting points, excellent mechanical properties, and resistance to corrosion, making it ideal for coating applications in demanding environments.

Key Applications:

- Hard Coatings: TiC films are widely applied in cutting tools, molds, and dies to enhance wear resistance and durability due to their hardness and toughness.

- Protective Coatings: TiC thin films are used for protective coatings in environments where components face extreme abrasion, corrosion, or high temperatures, such as in aerospace, automotive, and industrial machinery.

- Electrical Contacts: Due to its good electrical conductivity and corrosion resistance, TiC is used in coatings for electrical contacts in harsh environments.

- Semiconductors: TiC thin films are also used in semiconductor devices, where its thermal stability and electrical conductivity are beneficial for various electronic components.

- Optical Devices: TiC films can be used in optical devices for enhanced wear resistance and for specific reflective coatings due to its optical properties.

Features of TiC Sputtering Targets:

- High Hardness: TiC coatings provide excellent hardness, making them suitable for wear-resistant applications like cutting tools and dies.

- Corrosion Resistance: TiC films resist oxidation and corrosion, providing a protective barrier in harsh environments, including high-temperature applications.

- Thermal Stability: TiC has high thermal stability, making it ideal for coatings in high-temperature operations such as aerospace and automotive components.

- Electrical Conductivity: TiC exhibits good electrical conductivity, making it suitable for certain electronic and semiconductor applications where conductivity is critical.

- Chemical Resistance: TiC coatings offer chemical resistance, providing protective layers against corrosive agents and harsh chemicals.

Customization Options:

- Target Sizes: TiC sputtering targets are available in a variety of sizes and shapes, including round, rectangular, and custom dimensions, depending on the coating system requirements.

- Purity Levels: TiC targets come in different purity levels, typically up to 99.99%, ensuring high-quality film deposition for critical applications.

- Bonding Services: To enhance performance during sputtering, TiC targets can be bonded to backing plates, improving thermal conductivity and preventing target damage.

TiC (Titanium Carbide) sputtering targets from Tinsan Materials provide high hardness, corrosion resistance, and excellent wear protection for thin-film coatings. These targets are ideal for use in hard coatings, protective layers, and electrical applications, available in customizable sizes and purity levels.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.