TiN (Titanium Nitride) Sputtering Target

- High Hardness: TiN coatings are known for their exceptional hardness, making them ideal for cutting tools and components subject to high friction and stress.

- Corrosion Resistance: TiN provides excellent protection against corrosion and oxidation, extending the lifespan of coated parts and tools.

- High Temperature Stability: TiN remains stable at high temperatures, making it suitable for applications in high-temperature environments such as aerospace or industrial machinery.

- Good Electrical Conductivity: TiN is conductive and is often used in microelectronics as a barrier or adhesion layer in integrated circuits.

- Gold-Like Appearance: TiN has a bright gold color, making it popular for decorative applications and coatings in architectural elements and consumer products.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Titanium Nitrogen |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

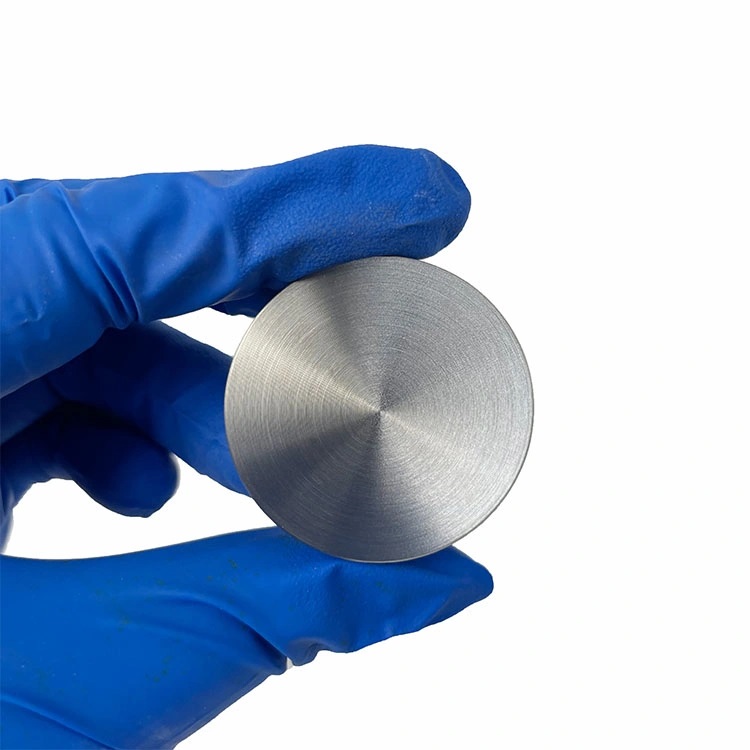

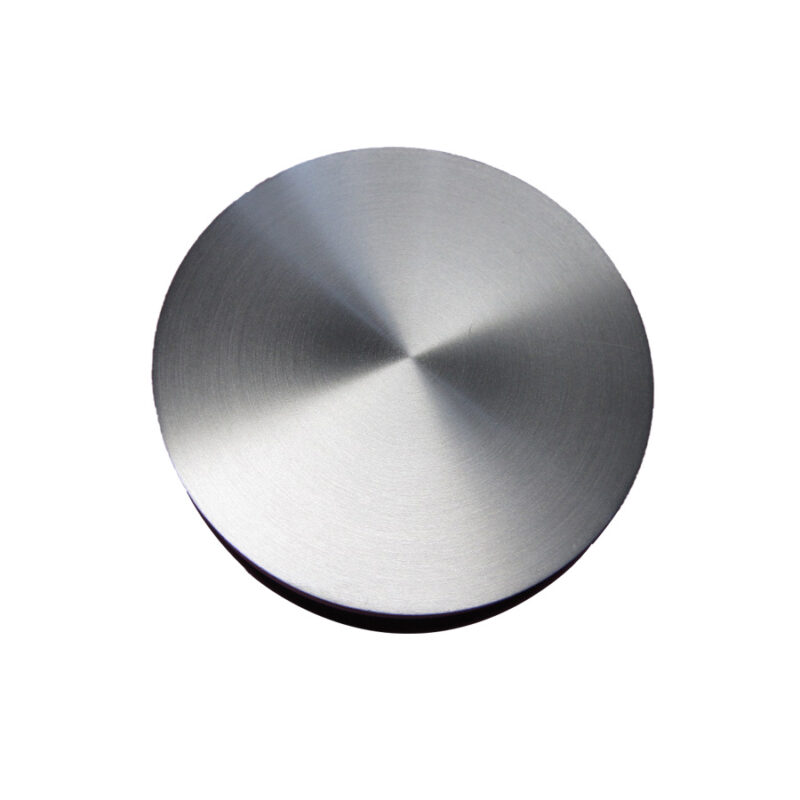

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

TiN (Titanium Nitride) sputtering targets are widely used for thin-film deposition in various industries due to their excellent hardness, chemical resistance, and high-temperature stability. TiN coatings are commonly applied in tools, electronics, optics, and decorative finishes.

Key Applications:

- Hard Coatings for Tools: TiN is widely used as a hard coating on cutting tools, drills, and machine parts. The coating enhances wear resistance and extends the service life of tools under extreme conditions.

- Semiconductors: In the semiconductor industry, TiN thin films are used as a diffusion barrier or adhesion layer in integrated circuits. Its conductivity and chemical stability make it an essential material in microelectronics.

- Optical Coatings: TiN’s gold-like appearance makes it a popular choice for decorative coatings, while its reflective properties make it useful in optical applications such as mirrors or anti-reflective layers.

- Biomedical Coatings: TiN coatings are applied to medical devices and implants to enhance biocompatibility, wear resistance, and corrosion protection.

- Wear-Resistant Coatings: TiN is used to coat mechanical components and surfaces exposed to high wear and friction, protecting them from corrosion, wear, and oxidation.

Features of TiN Sputtering Targets:

- High Hardness: TiN coatings are known for their exceptional hardness, making them ideal for cutting tools and components subject to high friction and stress.

- Corrosion Resistance: TiN provides excellent protection against corrosion and oxidation, extending the lifespan of coated parts and tools.

- High Temperature Stability: TiN remains stable at high temperatures, making it suitable for applications in high-temperature environments such as aerospace or industrial machinery.

- Good Electrical Conductivity: TiN is conductive and is often used in microelectronics as a barrier or adhesion layer in integrated circuits.

- Gold-Like Appearance: TiN has a bright gold color, making it popular for decorative applications and coatings in architectural elements and consumer products.

Customization Options:

- Dimensions: TiN sputtering targets are available in various shapes and sizes, including discs, rectangular plates, and custom geometries, to fit different sputtering systems.

- Purity: High-purity TiN sputtering targets (up to 99.99%) are available for high-performance applications where minimal contamination is essential, particularly in semiconductors and microelectronics.

- Doping: TiN targets can be doped with additional elements to modify properties such as electrical conductivity or mechanical strength for specific applications.

TiN (Titanium Nitride) sputtering targets from Tinsan Materials provide excellent hardness, corrosion resistance, and high-temperature stability for thin-film deposition in tools, semiconductors, optics, and decorative coatings. Custom sizes and high-purity options available.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.