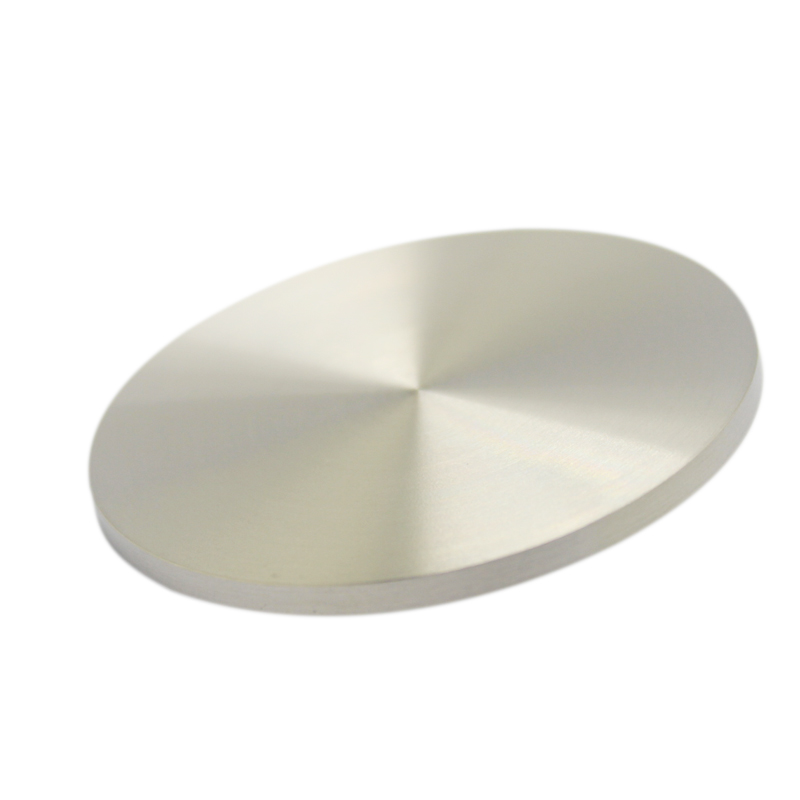

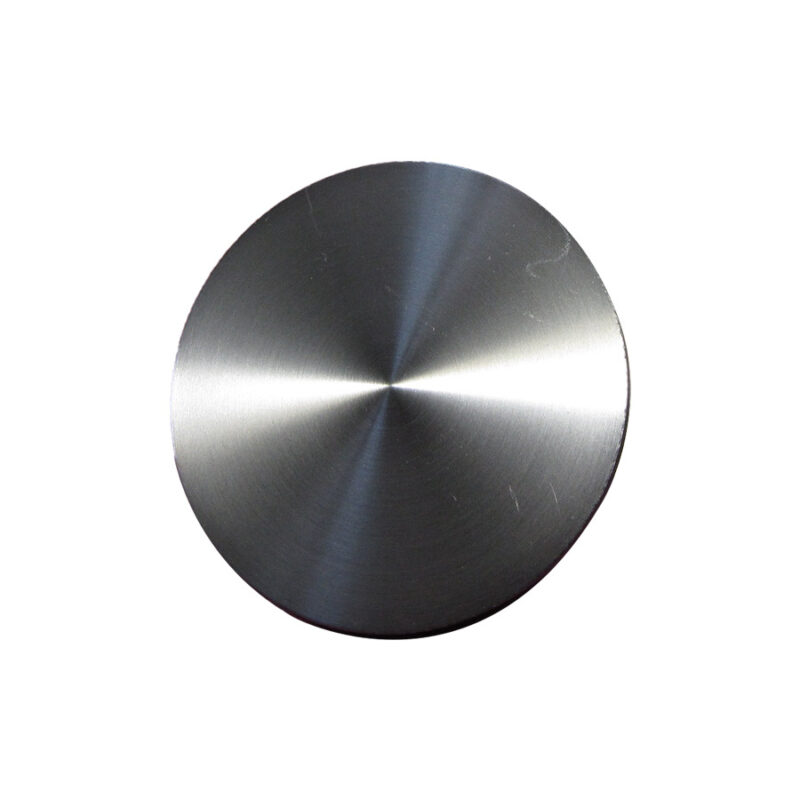

TiSb (Titanium Antimony) Sputtering Targets

- High Purity: Ensures consistent film quality and reduces defects in deposited layers.

- Stable Composition: Titanium and antimony alloying for enhanced mechanical and chemical properties.

- Versatile Applications: Compatible with a wide range of deposition techniques, including PVD and sputtering.

- Customizable Options: Available in various compositions and dimensions to meet specific requirements.

- Durability: Resistant to oxidation and corrosion, ensuring longevity during sputtering processes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Titanium Antimony (TiSb) |

| Purity | 99.5% – 99.9999% / 2N5 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Titanium Antimony (TiSb) sputtering targets are advanced materials made from a combination of titanium and antimony. These targets are widely utilized in thin-film deposition processes for creating high-quality coatings in semiconductor devices, optical films, and functional materials. TiSb sputtering targets are known for their excellent uniformity, high-purity composition, and superior adhesion properties, making them ideal for demanding industrial and research applications.

Key Applications

- Semiconductor Industry: For thin-film coatings in microelectronics and integrated circuits.

- Optical Coatings: Used in antireflective and reflective layers for optics and photonic devices.

- Data Storage: Applied in magnetic and phase-change memory materials.

- Energy Devices: Functional layers in solar cells and other energy harvesting devices.

- Research and Development: Ideal for the development of advanced materials in academic and industrial laboratories.

Features and Benefits

- High Purity: Ensures consistent film quality and reduces defects in deposited layers.

- Stable Composition: Titanium and antimony alloying for enhanced mechanical and chemical properties.

- Versatile Applications: Compatible with a wide range of deposition techniques, including PVD and sputtering.

- Customizable Options: Available in various compositions and dimensions to meet specific requirements.

- Durability: Resistant to oxidation and corrosion, ensuring longevity during sputtering processes.

Specifications

- Chemical Composition: Titanium (Ti) and Antimony (Sb) alloy.

- Purity: ≥ 99.5% (custom purity levels available upon request).

- Target Forms: Circular, rectangular, and custom geometries.

- Density: Dependent on the specific Ti-Sb composition ratio.

- Sizes: Standard and custom sizes available to suit different sputtering systems.

Customization Options

- Composition Ratios: Tailored Ti and Sb ratios to meet specific application needs.

- Dimensions: Custom sizes and shapes to accommodate various deposition systems.

- Bonding Services: Optional backing plate bonding for enhanced thermal and mechanical performance.

- Purity Levels: Ultra-high purity options for applications requiring minimal contamination.

Explore our high-quality Titanium Antimony (TiSb) sputtering targets and find the perfect solution for your thin-film coating needs. Contact us today to discuss your requirements and receive expert assistance.