Tungsten W Evaporation Boats

- Long lifespan due to exceptional wear resistance.

- Customizable design for specific applications.

- High purity ensures minimal contamination in sensitive processes.

- Suitable for both batch production and R&D applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

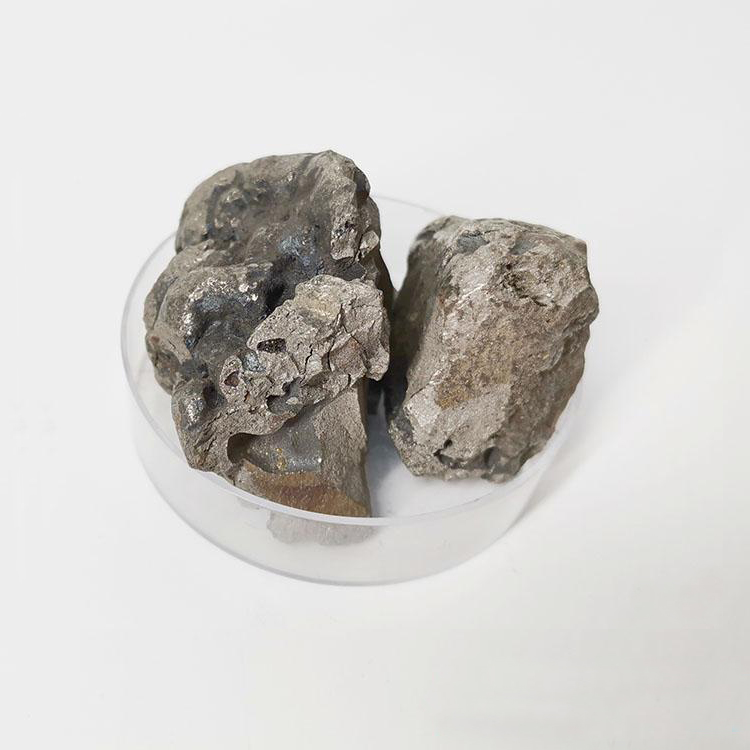

A Tungsten Boat is a high-purity component made of tungsten, widely used in industries requiring extreme thermal resistance and efficient material evaporation. Tungsten’s exceptional properties, such as a high melting point, excellent thermal and electrical conductivity, and resistance to corrosion, make it an ideal choice for high-temperature applications. These boats are shaped to hold materials during evaporation processes in a vacuum, ensuring uniform heating and deposition. Tungsten boats come in various shapes, such as U-shaped, V-shaped, or custom designs, to meet the specific requirements of different industries.

Their versatility and reliability make them essential tools in vacuum evaporation systems, thin-film coating, metallurgical processes, and advanced manufacturing techniques.

Properties:

- Material: Made from high-purity tungsten (typically ≥ 99.95%).

- Melting Point: Extremely high melting point (~3422°C), making it suitable for high-temperature applications.

- Thermal Stability: Excellent resistance to thermal deformation and chemical corrosion.

- Electrical Conductivity: Good electrical conductivity, enabling efficient heating in thermal evaporation systems.

- Durability: Resistant to wear and tear under extreme conditions.

- Shape and Size: Available in various shapes (e.g., U-shaped, V-shaped, box-type) and customizable dimensions.

Performance:

- High Temperature Resistance: Maintains structural integrity and performance in temperatures up to 2800°C.

- High Evaporation Efficiency: Uniform heating ensures consistent material evaporation.

- Corrosion Resistance: Chemically inert, even in aggressive environments.

- Thermal Shock Resistance: Can endure rapid temperature changes without cracking or deforming.

Applications:

- Vacuum Evaporation: Used to hold and heat materials for deposition in thin-film coating applications, such as optical coatings, semiconductors, and decorative finishes.

- Metallurgical Processes: Applied in the refining of metals and materials requiring high-temperature treatment.

- Electronic Manufacturing: Utilized in the production of electronic components such as solar cells, LEDs, and flat-panel displays.

- Research Laboratories: Commonly used in experimental setups for high-temperature material testing and vacuum evaporation studies.

- Aerospace and Defense: Employed in coating technologies for high-performance optics and thermal barrier systems.

Advantages:

- Long lifespan due to exceptional wear resistance.

- Customizable design for specific applications.

- High purity ensures minimal contamination in sensitive processes.

- Suitable for both batch production and R&D applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.