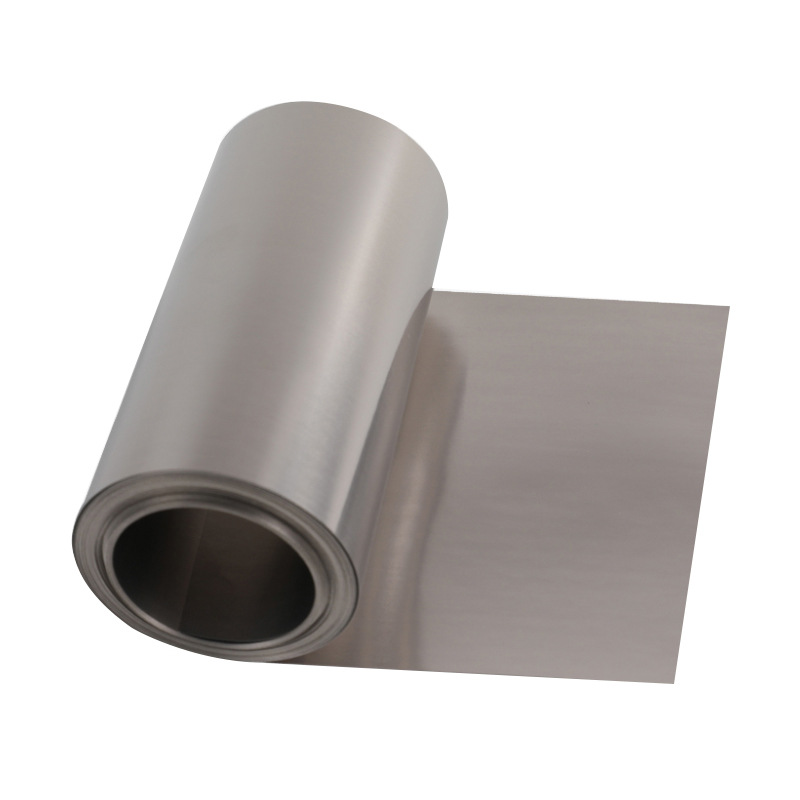

V Vanadium Foil

- High Strength-to-Weight Ratio: Vanadium foil is lightweight yet incredibly strong, making it suitable for aerospace and structural applications.

- Corrosion Resistance: Vanadium exhibits excellent resistance to oxidation and corrosion, especially in harsh environments.

- High Melting Point: With a melting point of 1,910°C (3,470°F), vanadium foil is highly resistant to heat, ideal for high-temperature applications.

- Ductility: Vanadium foil is ductile and can be processed into thin sheets or complex shapes without losing its structural integrity.

- Thermal and Electrical Conductivity: Vanadium offers good thermal and electrical conductivity, suitable for energy storage and electrical applications.

- Compatibility with Alloys: Vanadium can enhance the strength and wear resistance of other metals when used as an alloying element.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Vanadium foil is a highly specialized material known for its exceptional strength, corrosion resistance, and heat resistance. Its unique properties make it an ideal choice for applications in aerospace, energy, and chemical industries. Tinsan Materials provides premium-quality vanadium foil with customizable sizes and specifications to meet diverse industrial needs.

Properties of Vanadium Foil

- High Strength-to-Weight Ratio: Vanadium foil is lightweight yet incredibly strong, making it suitable for aerospace and structural applications.

- Corrosion Resistance: Vanadium exhibits excellent resistance to oxidation and corrosion, especially in harsh environments.

- High Melting Point: With a melting point of 1,910°C (3,470°F), vanadium foil is highly resistant to heat, ideal for high-temperature applications.

- Ductility: Vanadium foil is ductile and can be processed into thin sheets or complex shapes without losing its structural integrity.

- Thermal and Electrical Conductivity: Vanadium offers good thermal and electrical conductivity, suitable for energy storage and electrical applications.

- Compatibility with Alloys: Vanadium can enhance the strength and wear resistance of other metals when used as an alloying element.

Advantages of Vanadium Foil

- Lightweight and Strong: The combination of low weight and high strength makes vanadium foil essential for weight-sensitive industries like aerospace.

- High Heat Resistance: Vanadium foil performs reliably at extreme temperatures, reducing the risk of material degradation in high-heat environments.

- Corrosion and Oxidation Resistance: Vanadium’s resistance to oxidation and corrosion ensures long-lasting performance, even in chemically aggressive settings.

- Customizability: Vanadium foil can be tailored in thickness, size, and purity levels, allowing for versatile industrial applications.

- Sustainability: Vanadium is recyclable, making it a sustainable option for environmentally conscious industries.

Applications of Vanadium Foil

- Aerospace Industry: Used in jet engines, high-speed aircraft components, and structural parts due to its strength and heat resistance.

- Energy Storage and Batteries: Vanadium foil is used in vanadium redox flow batteries (VRFBs) for large-scale energy storage systems.

- Nuclear Industry: As a material for cladding and structural components in nuclear reactors, vanadium foil ensures safety and efficiency due to its resistance to radiation damage.

- Chemical Processing: Its corrosion resistance makes vanadium foil suitable for chemical reactors, heat exchangers, and storage tanks.

- Medical Applications: Vanadium foil is used in prosthetics, implants, and medical instruments due to its biocompatibility and durability.

- Superconducting Materials: Used in the production of superconducting magnets and other advanced technologies.

At Tinsan Materials, we offer vanadium foil in a variety of sizes, thicknesses, and purity levels to meet specific application requirements. Our advanced manufacturing processes ensure superior quality and precise customization for diverse industries.

If you have specific requirements, such as sizes, purity, or application details, please contact us to match your needs.