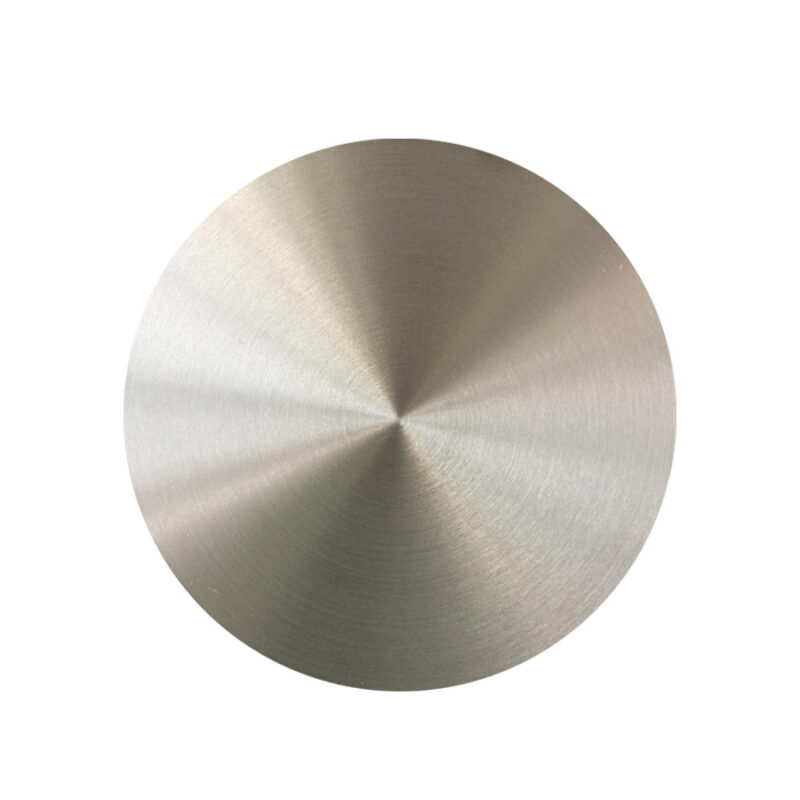

Vanadium Carbide (VC) Sputtering Targets

- Exceptional Hardness: Provides outstanding resistance to abrasion and wear.

- Chemical Stability: Maintains performance in harsh and reactive environments.

- High Thermal Conductivity: Efficiently dissipates heat in critical applications.

- Uniform Deposition: Ensures consistent film quality with minimal defects.

- Customizable Options: Available in various sizes and purities for specialized applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Vanadium Carbide (VC) |

| Purity | 99.5% – 99.9999% / 2N5 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Vanadium Carbide (VC) sputtering targets are advanced materials utilized in thin-film deposition processes, offering exceptional hardness, chemical stability, and thermal conductivity. These targets are ideal for producing wear-resistant coatings, decorative layers, and functional films in high-performance applications across various industries, including electronics, optics, and aerospace.

Key Applications

- Wear-Resistant Coatings: Extends the lifespan of tools, dies, and machine components.

- Decorative Films: Provides aesthetic finishes with enhanced durability.

- Electronic Components: Used in semiconductors and other high-performance electronic devices.

- Optical Coatings: Enhances reflectivity and durability in optical systems.

- Thermal Barrier Coatings: Protects components from high-temperature environments.

Features and Benefits

- Exceptional Hardness: Provides outstanding resistance to abrasion and wear.

- Chemical Stability: Maintains performance in harsh and reactive environments.

- High Thermal Conductivity: Efficiently dissipates heat in critical applications.

- Uniform Deposition: Ensures consistent film quality with minimal defects.

- Customizable Options: Available in various sizes and purities for specialized applications.

Specifications

- Purity: ≥99.5% for optimal thin-film quality.

- Density: Approx. 5.77 g/cm³.

- Shape: Available in planar, rotary, and custom shapes.

- Dimensions: Customizable to fit specific sputtering systems.

Customization Options

- Size and Shape: Tailored dimensions for your equipment and application needs.

- Purity Levels: Enhanced purity options for advanced applications.

- Backing Plates: Optional backing plates for improved thermal and mechanical stability.

Let our experts assist you in selecting the perfect VC sputtering target for your project. Contact us today to request a quote or learn more about our customization options.