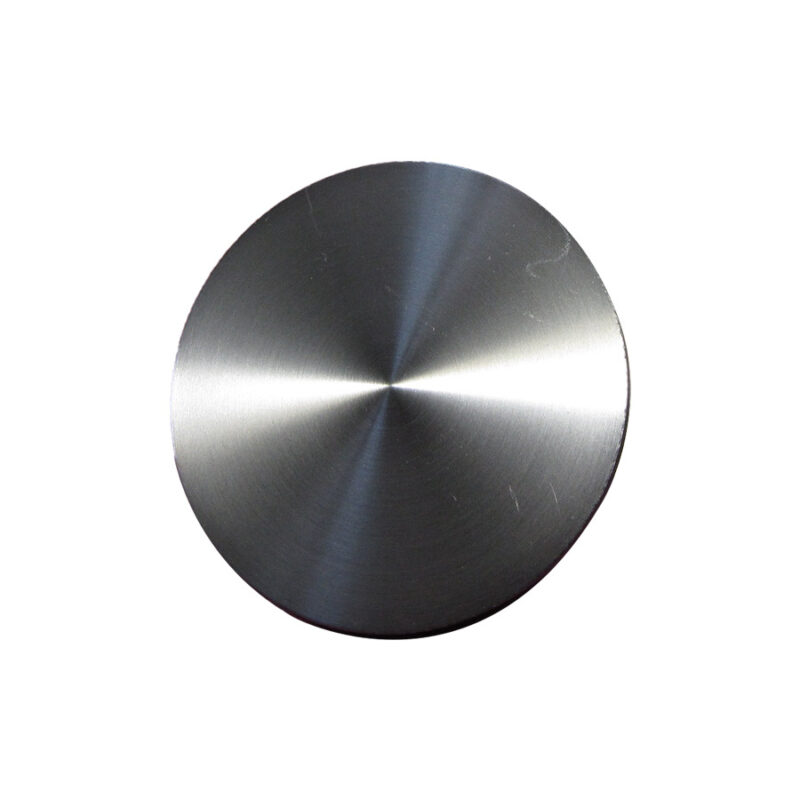

VSi2 (Vanadium Disilicide) Sputtering Targets

- Superior Electrical Conductivity: VSi₂ is an excellent conductor of electricity, making it ideal for applications where conductive coatings are required.

- High Thermal Stability: The material maintains its integrity under high temperatures, making it suitable for high-temperature applications.

- Hardness and Durability: Known for its wear resistance, VSi₂ is used in applications that demand exceptional durability and surface hardness.

- Corrosion Resistance: Offers good resistance to corrosion, particularly in aggressive environments.

- Customizable Sizes: Available in various sizes and thicknesses to meet specific application requirements.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Vanadium Disilicide (VSi₂) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Vanadium Disilicide (VSi₂) sputtering targets are advanced materials widely used in thin-film deposition processes, particularly in semiconductor manufacturing, microelectronics, and other high-performance applications. VSi₂ targets are favored for their excellent thermal stability, electrical conductivity, and hardness, making them suitable for the production of coatings that require superior performance under extreme conditions.

Key Applications

- Semiconductor Industry: Used in the fabrication of thin-film coatings for microelectronics, including gate materials and interconnects.

- Microelectronics & Thin Film Deposition: Ideal for producing high-quality conductive films in the fabrication of integrated circuits (ICs) and microelectromechanical systems (MEMS).

- Wear-Resistant Coatings: Employed for coatings requiring enhanced hardness and wear resistance in industries such as aerospace and automotive.

Features and Benefits

- Superior Electrical Conductivity: VSi₂ is an excellent conductor of electricity, making it ideal for applications where conductive coatings are required.

- High Thermal Stability: The material maintains its integrity under high temperatures, making it suitable for high-temperature applications.

- Hardness and Durability: Known for its wear resistance, VSi₂ is used in applications that demand exceptional durability and surface hardness.

- Corrosion Resistance: Offers good resistance to corrosion, particularly in aggressive environments.

- Customizable Sizes: Available in various sizes and thicknesses to meet specific application requirements.

Specifications

- Purity: Typically 99.9% or higher, ensuring high-performance sputtering results.

- Shape: Available as discs, planar, or custom shapes depending on the deposition system requirements.

- Dimensions: Custom sizes, ranging from small to large targets, available upon request.

- Density: Typically ranges around 6.4 g/cm³.

Customization Options

- Custom target shapes and sizes are available.

- Different purity levels upon request.

- Custom coatings can be applied for specific performance needs.

For more information or to request a quote, please contact us today. Our team is ready to assist you in selecting the perfect VSi₂ sputtering target for your application.