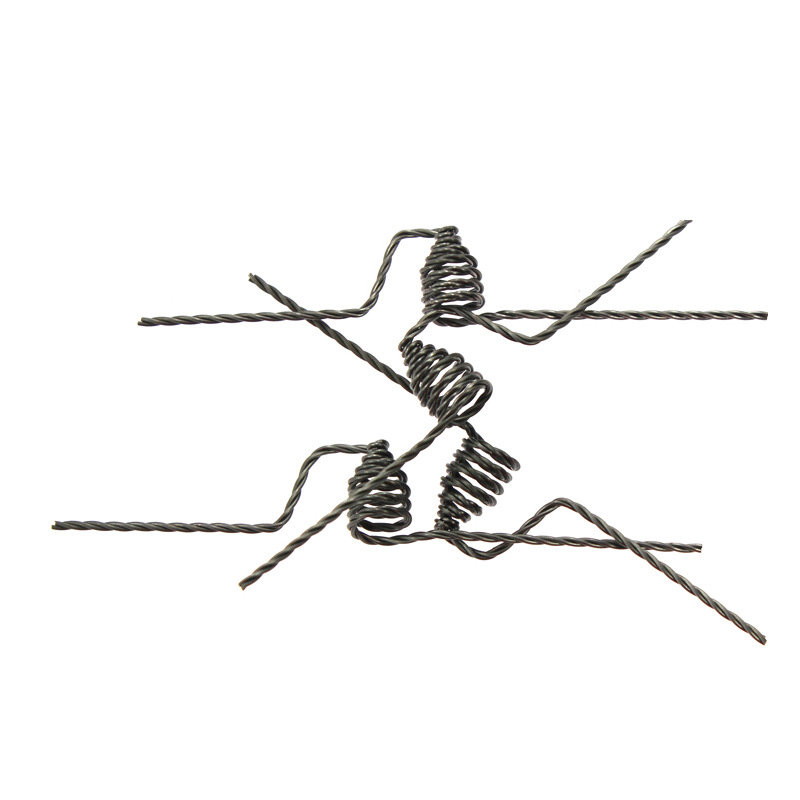

W Tungsten Wire Baskets

- High Melting Point: Tungsten has one of the highest melting points of any metal, at approximately 3,422°C (6,192°F). This property allows tungsten wire baskets to perform exceptionally well in high-temperature environments, such as in furnaces, aerospace applications, and high-energy industrial processes.

- Excellent Thermal Conductivity: Tungsten’s high thermal conductivity ensures that tungsten wire baskets distribute heat evenly, making them ideal for applications that require precise temperature control or rapid heat dissipation.

- Corrosion and Oxidation Resistance: Tungsten wire baskets exhibit excellent resistance to corrosion and oxidation, especially in environments with high temperatures and reactive gases. This makes them suitable for use in aggressive chemical environments where other metals may degrade.

- Mechanical Strength: Tungsten is known for its high mechanical strength and durability. Tungsten wire baskets can maintain structural integrity under high stress and heavy loads, making them suitable for industrial applications where strength and resilience are paramount.

- Density and Durability: Tungsten is a dense metal, which contributes to its durability and robustness. Tungsten wire baskets are strong yet stable, capable of supporting significant weights without deforming or losing their shape.

- Biocompatibility: Tungsten is biocompatible, making it suitable for use in medical applications. Although tungsten wire baskets are not commonly used in direct contact with biological tissues, their use in medical environments (e.g., sterilization or medical devices) requires biocompatibility.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Tungsten wire baskets are made from high-purity tungsten wire and are designed to withstand extreme conditions, including high temperatures and aggressive environments. Tungsten, known for its remarkable physical properties, including a high melting point and excellent resistance to thermal expansion, makes it an ideal material for various high-performance applications. Tungsten wire baskets are used across industries like aerospace, electronics, and the chemical industry, where durability, thermal resistance, and corrosion resistance are critical.

Properties of Tungsten Wire Baskets

- High Melting Point: Tungsten has one of the highest melting points of any metal, at approximately 3,422°C (6,192°F). This property allows tungsten wire baskets to perform exceptionally well in high-temperature environments, such as in furnaces, aerospace applications, and high-energy industrial processes.

- Excellent Thermal Conductivity: Tungsten’s high thermal conductivity ensures that tungsten wire baskets distribute heat evenly, making them ideal for applications that require precise temperature control or rapid heat dissipation.

- Corrosion and Oxidation Resistance: Tungsten wire baskets exhibit excellent resistance to corrosion and oxidation, especially in environments with high temperatures and reactive gases. This makes them suitable for use in aggressive chemical environments where other metals may degrade.

- Mechanical Strength: Tungsten is known for its high mechanical strength and durability. Tungsten wire baskets can maintain structural integrity under high stress and heavy loads, making them suitable for industrial applications where strength and resilience are paramount.

- Density and Durability: Tungsten is a dense metal, which contributes to its durability and robustness. Tungsten wire baskets are strong yet stable, capable of supporting significant weights without deforming or losing their shape.

- Biocompatibility: Tungsten is biocompatible, making it suitable for use in medical applications. Although tungsten wire baskets are not commonly used in direct contact with biological tissues, their use in medical environments (e.g., sterilization or medical devices) requires biocompatibility.

Advantages of Tungsten Wire Baskets

- Extreme Temperature Resistance: Tungsten wire baskets are resistant to extremely high temperatures, making them ideal for use in furnace systems, aerospace, and high-energy applications.

- Chemical Resistance: The corrosion-resistant nature of tungsten ensures that the wire baskets remain intact even when exposed to harsh chemicals or reactive gases, which is a critical property for use in chemical processing and laboratory environments.

- Long Life Span: Tungsten’s high mechanical strength and thermal resistance contribute to the long lifespan of tungsten wire baskets, even under the harshest conditions.

- High Durability: Tungsten wire baskets can withstand physical stress and are suitable for heavy-duty applications, providing reliability in demanding environments.

- Heat Distribution: The high thermal conductivity of tungsten wire baskets allows for efficient heat distribution, which is essential in various industrial processes where temperature control is crucial.

- Stable and Strong: Tungsten’s high density and strength ensure that the baskets maintain their shape and stability under pressure, even when used with heavy materials.

Applications of Tungsten Wire Baskets

- Aerospace and Aviation: In the aerospace industry, tungsten wire baskets are used in various high-temperature environments, such as in furnace components and equipment used for heat treatment of aerospace materials. Their ability to withstand extreme temperatures and stresses makes them ideal for components in rocket engines, turbine blades, and high-performance aerospace systems.

- Electronics Industry: Tungsten wire baskets are employed in the electronics industry, particularly in semiconductor production. They are used for carrying wafers and components during the heat treatment or deposition processes in semiconductor manufacturing due to their ability to resist high temperatures and corrosion.

- Chemical Processing: Due to their resistance to chemical corrosion, tungsten wire baskets are used in chemical processing plants where high temperatures and aggressive chemicals are present. They are ideal for applications such as chemical reactors, high-temperature furnaces, and other systems exposed to reactive chemicals.

- Heat Treatment: Tungsten wire baskets are used in heat treatment processes where high temperatures are required. They can hold materials being processed in furnaces, ensuring uniform heating and avoiding contamination in high-temperature environments.

- Laboratory and Research: Tungsten wire baskets are also used in laboratory environments for high-temperature applications such as in sintering furnaces, chemical vapor deposition (CVD) chambers, or other high-temperature research setups.

- Medical Devices: Tungsten wire baskets can be used in medical sterilization processes due to their corrosion resistance and high-temperature endurance. They are also used in the processing of medical materials that require high heat or protection from contamination.

- Melt Processing: Tungsten wire baskets are used for the processing and holding of molten metals, especially in industries where high melting points are required, such as in the production of specialty alloys.

Customization Options for Tungsten Wire Baskets

- Wire Gauge: Tungsten wire baskets can be made using different wire gauges depending on the required strength and load-bearing capacity for a given application.

- Shape and Size: Tungsten wire baskets can be customized in various shapes, including cylindrical, rectangular, or custom designs tailored to specific customer needs. Size can also be adjusted based on the amount and type of materials to be processed.

- Surface Finish: The surface finish of tungsten wire baskets can be customized for smoother surfaces or more textured finishes, depending on the application, such as reducing friction or ensuring better heat dissipation.

- Plating or Coating: Tungsten wire baskets can be coated or plated with other materials to enhance their properties, such as improving surface smoothness, enhancing corrosion resistance, or providing additional heat-resistant coatings for specific processes.

Tinsan Materials provides high-quality tungsten wire baskets designed to meet the demanding requirements of industries such as aerospace, electronics, and chemical processing. Our tungsten wire baskets are manufactured to the highest standards to ensure durability, reliability, and optimal performance in extreme conditions.

If you have specific requirements, such as diameters, purity, or application details, please contact us to match your needs.