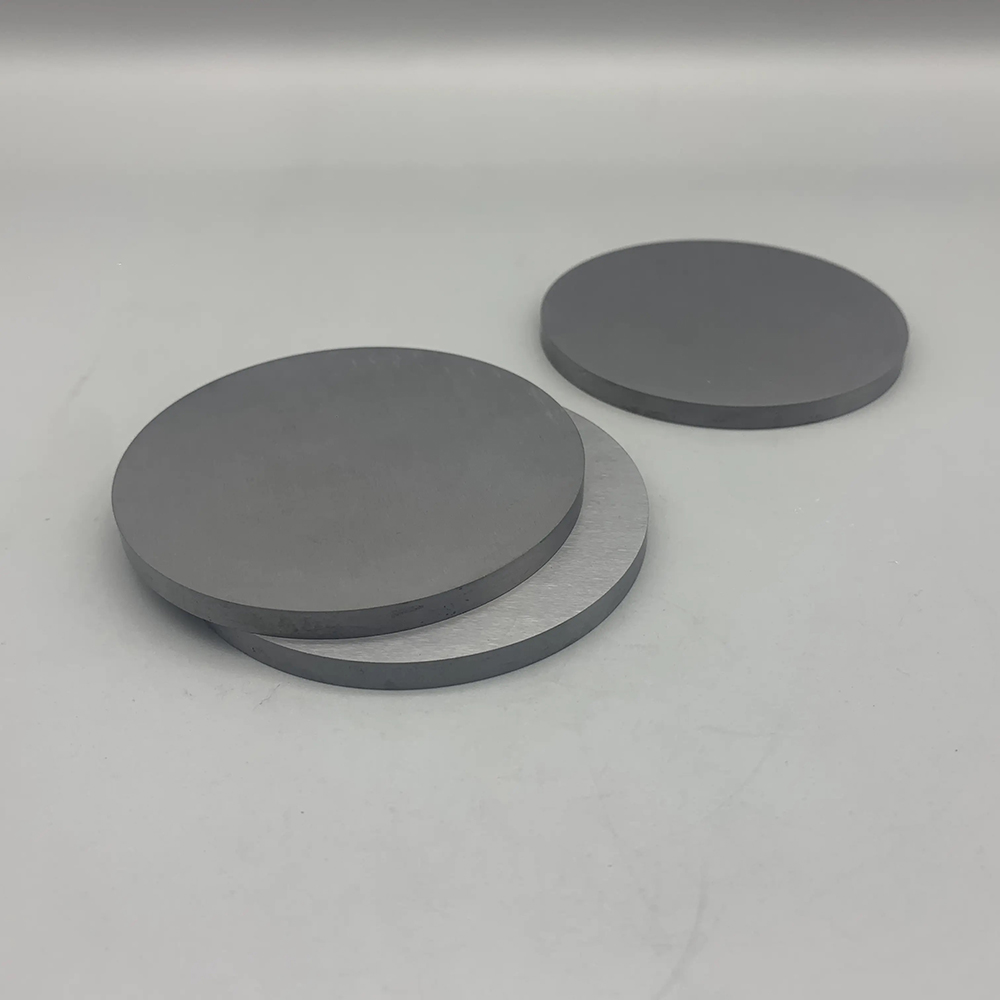

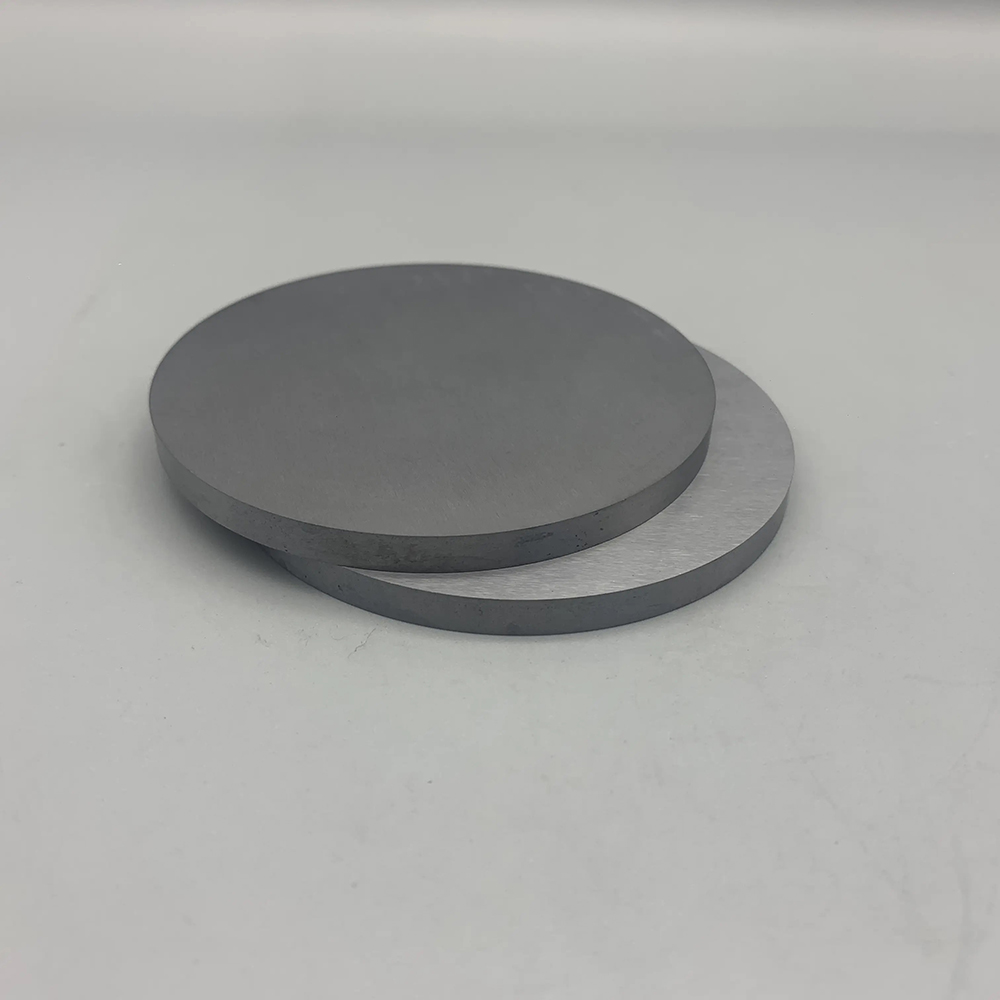

WC (Tungsten Carbide) Sputtering Target

- Exceptional Hardness: WC films offer high hardness, contributing to their use in tools and wear-resistant coatings.

- Thermal Stability: Tungsten Carbide thin films can withstand high temperatures without degrading, making them suitable for high-temperature environments.

- High Melting Point: WC has a melting point above 2,870°C, ensuring it retains its structural integrity in extreme conditions.

- Corrosion Resistance: WC coatings provide strong resistance against corrosion, enhancing the longevity of components used in harsh environments.

- Excellent Adhesion: WC sputtered films adhere well to various substrates, including metals and ceramics, ensuring durability and longevity of the coatings.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | WC |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

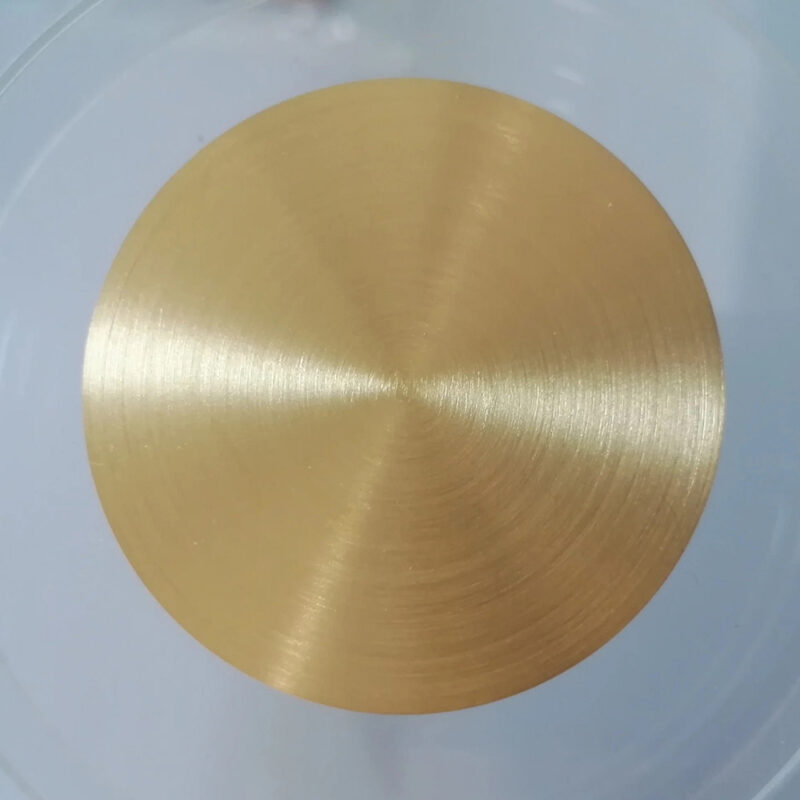

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tungsten Carbide (WC) sputtering targets are widely used in thin film deposition for applications requiring exceptional hardness, wear resistance, and high-temperature performance. WC is known for its extreme durability, making it suitable for coatings in cutting tools, protective layers, and various industrial applications.

Key Applications:

- Cutting Tools and Wear-Resistant Coatings: WC thin films provide superior hardness and wear resistance, ideal for enhancing the durability of cutting tools, drills, and dies.

- Protective Coatings: Tungsten Carbide is used in creating robust protective coatings for components exposed to high temperatures and abrasive environments, such as in aerospace and automotive industries.

- Optoelectronics and Microelectronics: WC sputtered films serve as conductive and diffusion barriers in the manufacturing of microelectronics, offering high resistance to corrosion and oxidation.

- Thermal Barrier Coatings: WC is also applied in high-temperature environments as a thermal barrier due to its excellent heat resistance and stability.

Features of WC Sputtering Targets:

- Exceptional Hardness: WC films offer high hardness, contributing to their use in tools and wear-resistant coatings.

- Thermal Stability: Tungsten Carbide thin films can withstand high temperatures without degrading, making them suitable for high-temperature environments.

- High Melting Point: WC has a melting point above 2,870°C, ensuring it retains its structural integrity in extreme conditions.

- Corrosion Resistance: WC coatings provide strong resistance against corrosion, enhancing the longevity of components used in harsh environments.

- Excellent Adhesion: WC sputtered films adhere well to various substrates, including metals and ceramics, ensuring durability and longevity of the coatings.

Customization Options:

- Target Sizes: Available in various diameters, thicknesses, and shapes to fit specific sputtering systems.

- Purity Levels: High-purity WC targets are provided to ensure optimal performance in critical applications.

- Bonding Services: WC targets can be bonded to backing plates to improve thermal management during the sputtering process.

Tinsan Materials provides high-quality WC (Tungsten Carbide) sputtering targets for thin film deposition in cutting tools, wear-resistant coatings, and industrial applications. WC films offer extreme hardness, thermal stability, and corrosion resistance, ideal for demanding environments.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.