WO3 (Tungsten Trioxide) Sputtering Targets

- High Melting Point: WO₃ has a high melting point (~1473°C), making it suitable for high-temperature applications.

- Chemical Stability: WO₃ is chemically stable and resistant to oxidation, ensuring long-term reliability in harsh environments.

- Transparency Control: WO₃ films can be engineered for transparency modulation, useful in smart glass and energy-efficient windows.

- High Conductivity: When doped or treated, WO₃ can exhibit increased electrical conductivity for various electronic applications.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Tungsten Trioxide (WO₃) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

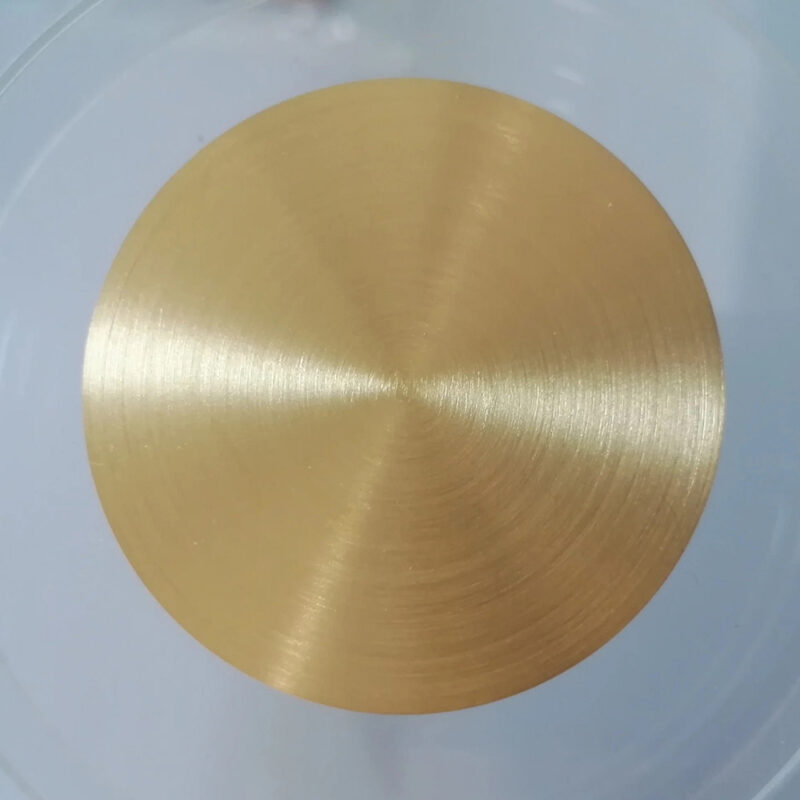

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tungsten Trioxide (WO₃) sputtering targets are widely used in various thin-film deposition applications. WO₃ is a transition metal oxide with excellent chemical stability and high melting point, making it suitable for high-temperature processes. These targets are often used in the preparation of high-performance coatings for electronics, optics, and energy storage devices.

Key Applications

- Electrochromic Devices: WO₃ thin films are used in electrochromic devices such as smart windows and mirrors, where they change color in response to an applied voltage.

- Gas Sensors: WO₃ is utilized in gas sensing applications, particularly for detecting gases like NO₂ and CO.

- Optical Coatings: WO₃ films can be used in optical coatings that require high stability and optical transmittance control.

- Energy Storage Devices: WO₃-based thin films are used in lithium-ion batteries and supercapacitors for energy storage applications.

- Catalysis: WO₃ is employed as a catalyst or in catalysis-related applications, including photocatalytic processes.

Features and Benefits

- High Melting Point: WO₃ has a high melting point (~1473°C), making it suitable for high-temperature applications.

- Chemical Stability: WO₃ is chemically stable and resistant to oxidation, ensuring long-term reliability in harsh environments.

- Transparency Control: WO₃ films can be engineered for transparency modulation, useful in smart glass and energy-efficient windows.

- High Conductivity: When doped or treated, WO₃ can exhibit increased electrical conductivity for various electronic applications.

Specifications

- Composition: 99.9% pure tungsten trioxide (WO₃)

- Size: Customizable to suit specific deposition needs, with diameters typically ranging from 50 mm to 200 mm.

- Thickness: Available in various thicknesses based on the application, typically from 1 mm to 10 mm.

- Density: Typically around 7.16 g/cm³.

- Purity: Available in high-purity forms (99.9% or higher) to ensure optimal performance in sensitive applications.

Customization Options

- Size and Shape: Custom sizes and shapes available to meet specific deposition chamber requirements.

- Purity Levels: Various purity options, including 99.99%, 99.999% and 99.9999%, depending on application needs.

- Target Surface Treatment: Surface treatments such as polishing or conditioning may be provided for enhanced film quality and sputtering performance.

For custom WO₃ sputtering targets, specific sizes, and detailed technical assistance, please contact our sales team. We offer tailored solutions to meet the unique requirements of your application.