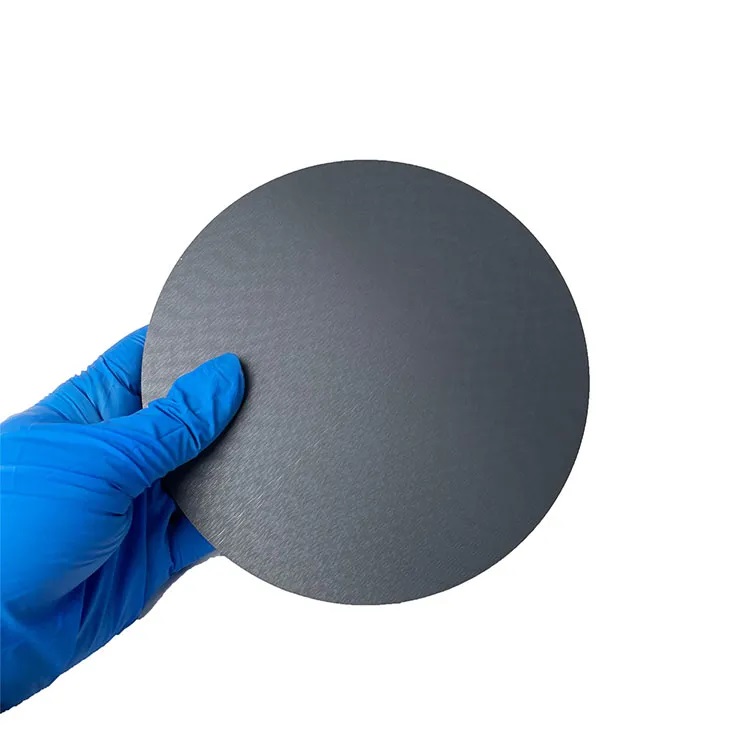

WS2 (Tungsten Disulfide) Sputtering Target

- Low Friction Coefficient: WS2 thin films exhibit an extremely low coefficient of friction, which is beneficial for improving the performance of mechanical systems in high-friction environments.

- Thermal Stability: WS2 coatings maintain their properties at elevated temperatures, making them suitable for high-temperature applications.

- High Wear Resistance: WS2 offers exceptional wear resistance, extending the operational life of coated components subjected to abrasive conditions.

- Chemical Inertness: WS2 is resistant to corrosion and oxidation, making it durable in harsh chemical environments.

- Layered Structure: The unique layered structure of WS2 provides excellent lubricating properties due to the easy shearing between layers.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | WS2 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Tungsten Disulfide (WS2) sputtering targets are widely utilized for thin film deposition in applications requiring solid lubrication, low friction, and high temperature resistance. WS2 is a layered transition metal dichalcogenide (TMD) with excellent tribological properties, making it a popular material in industries such as aerospace, automotive, and electronics.

Key Applications:

- Solid Lubrication: WS2 thin films are ideal for reducing friction in mechanical systems, especially in aerospace and automotive industries, where lubricants are needed under extreme conditions.

- Wear-Resistant Coatings: WS2 is used to deposit wear-resistant layers on components exposed to high loads and abrasive environments, enhancing durability and lifespan.

- Semiconductor and Electronics: WS2 films are utilized in semiconductor applications, as they exhibit promising electrical properties and are being explored for use in transistors, optoelectronic devices, and sensors.

- Low-Friction Coatings: WS2 is applied as a low-friction coating in mechanical systems, helping to reduce energy losses and increase efficiency in moving parts.

Features of WS2 Sputtering Targets:

- Low Friction Coefficient: WS2 thin films exhibit an extremely low coefficient of friction, which is beneficial for improving the performance of mechanical systems in high-friction environments.

- Thermal Stability: WS2 coatings maintain their properties at elevated temperatures, making them suitable for high-temperature applications.

- High Wear Resistance: WS2 offers exceptional wear resistance, extending the operational life of coated components subjected to abrasive conditions.

- Chemical Inertness: WS2 is resistant to corrosion and oxidation, making it durable in harsh chemical environments.

- Layered Structure: The unique layered structure of WS2 provides excellent lubricating properties due to the easy shearing between layers.

Customization Options:

- Target Sizes: Available in various sizes, thicknesses, and shapes to meet different sputtering system requirements.

- Purity Levels: High-purity WS2 targets are available for high-performance applications.

- Bonding Services: WS2 targets can be bonded to backing plates for improved thermal management during the sputtering process.

Tinsan Materials offers high-quality WS2 (Tungsten Disulfide) sputtering targets for thin film deposition. WS2 films provide solid lubrication, low friction, wear resistance, and high temperature stability for aerospace, automotive, and electronics applications.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.