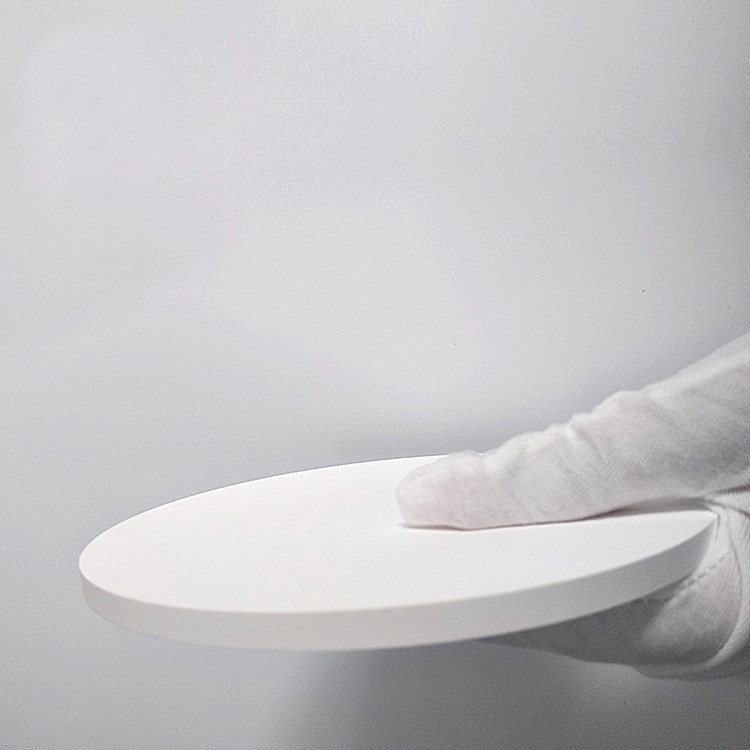

YF3 (Yttrium Trifluoride) Sputtering Targets

- Low Refractive Index: YF₃ films offer a low refractive index, making them ideal for anti-reflective coatings and optical thin films.

- High Purity: Available in ≥99.9% purity, ensuring clean deposition and minimal contamination in thin-film applications.

- Chemical Resistance: Resistant to acid and alkali, making it suitable for harsh environments.

- Optical Transparency: High optical transparency in the UV and visible spectra, enhancing the performance of optical coatings.

- Durability: Offers excellent mechanical properties and resistance to environmental degradation, ensuring long-term stability.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Yttrium Trifluoride (YF₃) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Yttrium trifluoride (YF₃) sputtering targets are high-performance materials used for the deposition of yttrium fluoride thin films. Known for their excellent optical properties, YF₃ targets are used in applications like optical coatings, laser systems, and advanced semiconductor technologies. YF₃ films exhibit low refractive indices and are resistant to environmental degradation, making them ideal for high-tech applications requiring superior durability and performance.

Key Applications

- Optical Coatings: YF₃ is widely used in optical coatings due to its low refractive index, excellent transparency, and resistance to scratches and chemical damage.

- Laser Systems: Used in the fabrication of optical components for laser systems, such as mirrors, windows, and beam splitters.

- Semiconductor Devices: Employed in advanced semiconductor processes, especially for devices requiring precise and durable coatings.

- Dielectrics: In microelectronics, YF₃ films serve as dielectric materials with high insulating properties.

- Solar Cells and Displays: Used for transparent conductive coatings and as part of the functional layers in photovoltaic cells and display devices.

Features and Benefits

- Low Refractive Index: YF₃ films offer a low refractive index, making them ideal for anti-reflective coatings and optical thin films.

- High Purity: Available in ≥99.9% purity, ensuring clean deposition and minimal contamination in thin-film applications.

- Chemical Resistance: Resistant to acid and alkali, making it suitable for harsh environments.

- Optical Transparency: High optical transparency in the UV and visible spectra, enhancing the performance of optical coatings.

- Durability: Offers excellent mechanical properties and resistance to environmental degradation, ensuring long-term stability.

Specifications

- Purity: ≥99.9%

- Density: Approx. 4.10 g/cm³

- Shapes Available: Circular, rectangular, or custom shapes to suit specific deposition systems.

- Sizes: Custom sizes available based on sputtering system requirements.

- Surface Finish: High-quality surface finish for smooth and consistent thin-film deposition.

Customization Options

- Target Shape and Size: Custom shapes and sizes to fit specific sputtering equipment and application needs.

- Purity Levels: Higher purity grades available upon request for critical applications.

- Backing Plate Materials: Available with various backing plate materials to ensure thermal stability and efficient target cooling.

For high-performance YF₃ sputtering targets and customized solutions, contact us today. Our expert team is ready to help with your thin-film deposition needs, providing reliable materials for a wide range of applications.