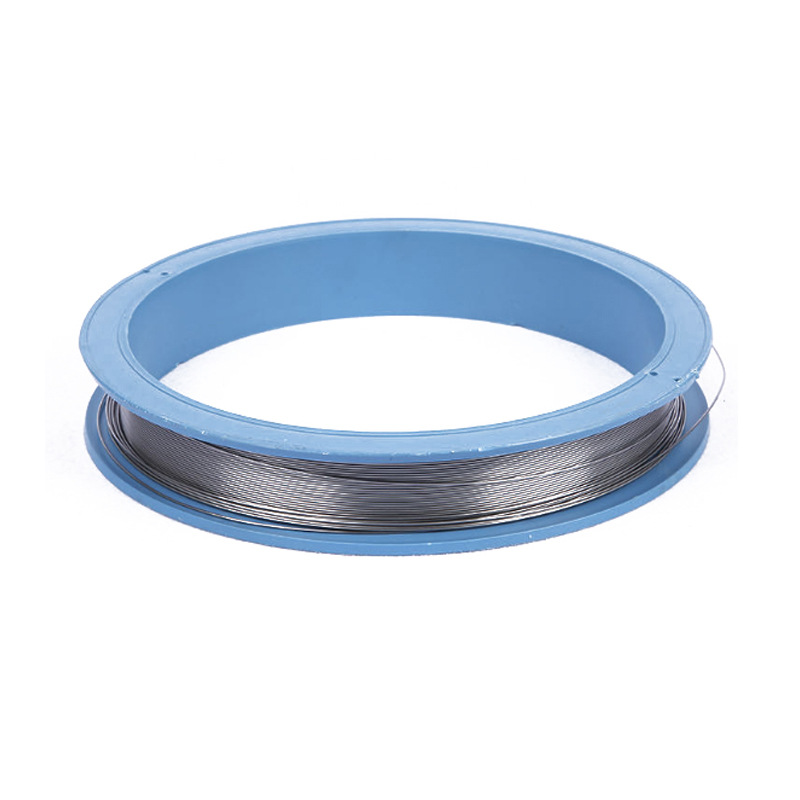

Zn Zinc Wire

- Efficient Corrosion Protection: Widely used for anti-corrosion coatings, zinc wire prolongs the lifespan of steel and other metals in harsh environments.

- Ease of Application: Zinc wire is easily applied using thermal spray techniques or galvanizing, offering uniform and durable coatings.

- Cost-Effectiveness: Zinc wire provides a cost-effective solution for protecting structures and components compared to other anti-corrosion methods.

- Customizability: Available in various diameters and purity levels, zinc wire can be tailored to meet specific industrial needs.

- Eco-Friendly: Zinc coatings are recyclable and environmentally safe, adhering to sustainable manufacturing practices.

- Excellent Bonding Properties: Zinc wire adheres well to a variety of substrates, ensuring long-lasting and reliable coatings.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Zinc wire is a versatile material widely utilized in industrial, automotive, and construction sectors for its excellent corrosion resistance and versatility. It is commonly used in thermal spray coatings, galvanizing processes, and as an alloying material. Below is an in-depth overview of the properties, advantages, and applications of zinc wire.

Key Properties of Zinc Wire

- Corrosion Resistance: Zinc wire forms a protective layer of zinc oxide when exposed to air, providing excellent corrosion protection.

- Low Melting Point: Zinc wire melts at approximately 419.5°C (787.1°F), making it ideal for thermal spraying and galvanizing applications.

- Ductility: The material’s high ductility allows it to be formed into thin wires without cracking, enabling precise applications.

- High Purity: Available in high-purity grades (up to 99.99%), ensuring consistent performance in demanding processes.

- Environmental Stability: Resistant to harsh weather conditions, making it suitable for outdoor and marine applications.

- Electrical Conductivity: Zinc wire offers moderate electrical conductivity, beneficial for certain electronic and thermal applications.

Advantages of Zinc Wire

- Efficient Corrosion Protection: Widely used for anti-corrosion coatings, zinc wire prolongs the lifespan of steel and other metals in harsh environments.

- Ease of Application: Zinc wire is easily applied using thermal spray techniques or galvanizing, offering uniform and durable coatings.

- Cost-Effectiveness: Zinc wire provides a cost-effective solution for protecting structures and components compared to other anti-corrosion methods.

- Customizability: Available in various diameters and purity levels, zinc wire can be tailored to meet specific industrial needs.

- Eco-Friendly: Zinc coatings are recyclable and environmentally safe, adhering to sustainable manufacturing practices.

- Excellent Bonding Properties: Zinc wire adheres well to a variety of substrates, ensuring long-lasting and reliable coatings.

Applications of Zinc Wire

- Thermal Spray Coatings: Widely used for applying anti-corrosion coatings on bridges, pipelines, steel structures, and machinery components.

- Hot-Dip Galvanizing: Zinc wire is a key material in galvanizing processes, providing robust protection for metal parts against rust and corrosion.

- Alloy Production: Used as an alloying material in brass, bronze, and other metal alloys to enhance strength and corrosion resistance.

- Cathodic Protection: Applied in marine environments to protect ships, docks, and underwater pipelines from corrosion.

- Electronics and Batteries: Utilized in the production of batteries, electrical components, and semiconductors.

- Aerospace and Automotive: Zinc wire coatings are used to enhance the durability and longevity of parts exposed to extreme conditions.

- Construction: Zinc wire is used to protect steel reinforcement in concrete structures, ensuring durability and reducing maintenance costs.

Grades and Specifications

Zinc wire is available in various grades depending on the application:

- High-Purity Zinc Wire (99.99%): For critical applications like electronics and thermal spray coatings.

- Standard Purity Zinc Wire (99.9%): For general galvanizing and industrial applications.

The wire can be manufactured in different diameters to meet the precise requirements of the end-use application.

Why Choose Zinc Wire from Tinsan Materials?

At Tinsan Materials, we offer premium-quality zinc wire with consistent purity and performance. Our zinc wire is manufactured to meet stringent quality standards, ensuring optimal results for your projects. We provide customization options for diameter, grade, and packaging to suit diverse industrial needs.

Zinc wire is a versatile and reliable material offering exceptional corrosion resistance, ease of application, and cost-effectiveness. It is a vital component in industries such as construction, automotive, electronics, and marine engineering. Choose zinc wire from us for superior quality and customized solutions tailored to your requirements.

Contact us today to discuss your zinc wire needs and explore our comprehensive range of materials!