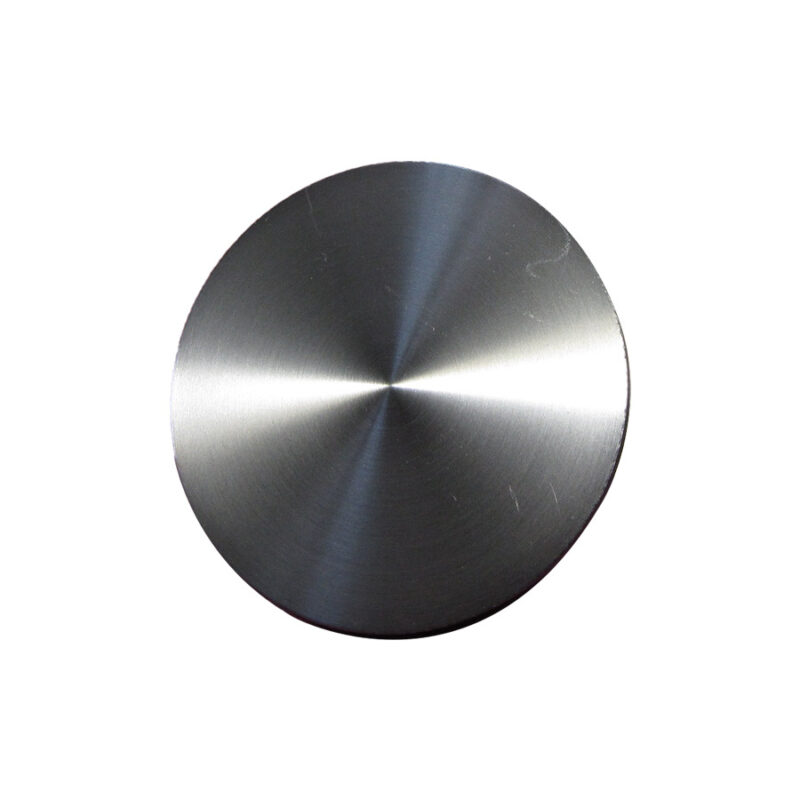

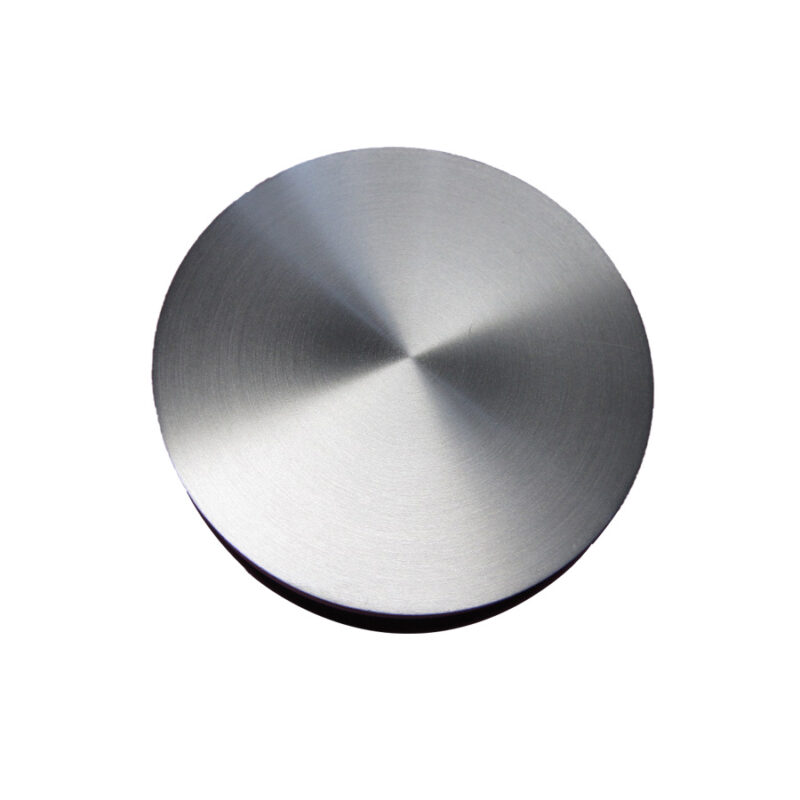

ZnTe (Zinc Telluride) Sputtering Targets

- Optoelectronic Properties: ZnTe is highly valued for its ability to efficiently emit light, making it a key material in optoelectronics and LEDs.

- High Purity: Available in various purity levels (99.9%, 99.99%, and higher) to ensure high-quality thin films.

- Thermal Stability: ZnTe maintains its properties under high-temperature conditions, making it suitable for high-performance applications.

- Customizable Sizes: Available in different diameters and thicknesses for a wide range of sputtering systems.

- Wide Application Range: Ideal for use in numerous industries, including renewable energy, communications, and infrared sensing.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Zinc Telluride (ZnTe) |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

ZnTe (Zinc Telluride) sputtering targets are high-quality materials used in the deposition of thin films for various high-tech applications, particularly in optoelectronics and semiconductors. Known for its unique electronic and optical properties, ZnTe is widely used in the production of devices such as light-emitting diodes (LEDs), laser diodes, and photovoltaic cells. The material also finds applications in infrared technology and photodetectors. ZnTe sputtering targets provide excellent consistency, high purity, and optimal film quality during deposition processes, ensuring the reliability of devices in demanding applications.

Key Applications

- Optoelectronics: Utilized in the production of LEDs, laser diodes, and other light-emitting devices.

- Photovoltaic Cells: Employed in the fabrication of thin-film solar cells and other renewable energy applications.

- Infrared Technology: Used in the development of infrared sensors and detectors.

- Semiconductor Industry: Ideal for the fabrication of semiconductor devices, including those used in telecommunications and computing.

- Optical Coatings: Used for depositing thin films for optical coatings and mirrors.

Features and Benefits

- Optoelectronic Properties: ZnTe is highly valued for its ability to efficiently emit light, making it a key material in optoelectronics and LEDs.

- High Purity: Available in various purity levels (99.9%, 99.99%, and higher) to ensure high-quality thin films.

- Thermal Stability: ZnTe maintains its properties under high-temperature conditions, making it suitable for high-performance applications.

- Customizable Sizes: Available in different diameters and thicknesses for a wide range of sputtering systems.

- Wide Application Range: Ideal for use in numerous industries, including renewable energy, communications, and infrared sensing.

Specifications

- Purity: 99.9%, 99.99%, 99.999%, 99.9999% available.

- Diameter: Custom diameters to meet specific sputtering system requirements.

- Thickness: Customizable thicknesses based on application needs.

- Form: Disc, circular, or custom shapes based on customer requirements.

- Target Material: High-purity ZnTe for consistent film deposition quality.

Customization Options

- Custom Sizing: Targets can be tailored in terms of diameter and thickness to fit specific sputtering systems.

- Purity Levels: Available in different purity grades, depending on the specific requirements of your application.

- Back Plates: Optional backing materials and customizations for enhanced sputtering performance.

- Packaging Options: Bulk and custom packaging options are available for large orders.

For more information on ZnTe sputtering targets or to request a quote, contact us today. Our team is dedicated to providing the right material for your thin-film deposition needs.