ZrC (Zirconium Carbide) Pellets Granules Evaporation Materials

- High Melting Point: ZrC has an extremely high melting point (~3,530°C), making it suitable for high-temperature applications.

- Excellent Hardness and Wear Resistance: It provides outstanding hardness, making it ideal for protective coatings and applications requiring high durability.

- Good Thermal and Electrical Conductivity: ZrC exhibits metallic-like conductivity, which is beneficial for electrical applications and high-heat environments.

- Corrosion and Oxidation Resistance: Highly resistant to chemical attack, corrosion, and oxidation, even in harsh conditions.

- Low Density: Compared to other refractory materials, ZrC has a relatively low density, making it advantageous in aerospace applications where weight is a critical factor.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | Zirconium Carbide (ZrC) |

| Purity | 99.5% – 99.999% / 2N5 3N 3N5 4N 4N5 5N |

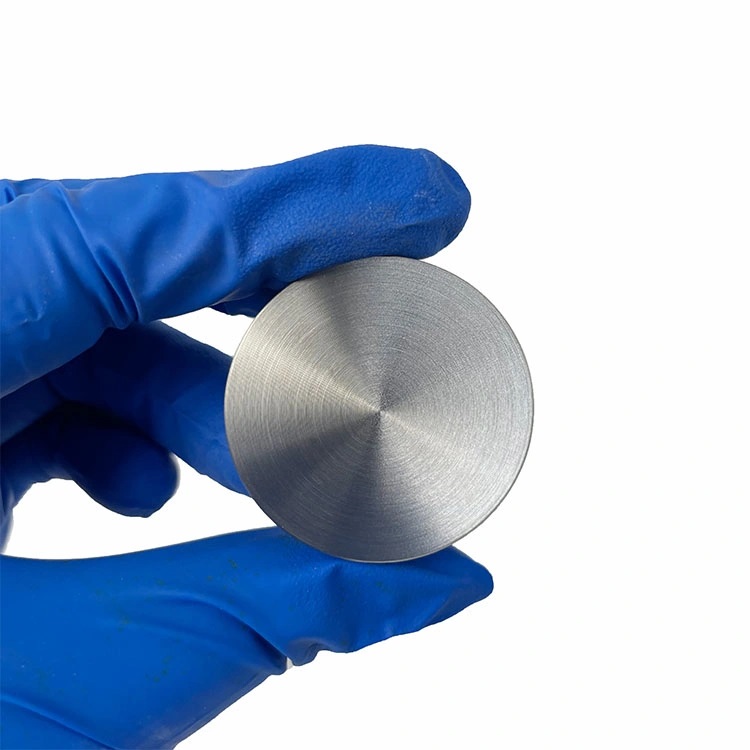

| Shape | Pellets / Granules / Particles / Pieces |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| Supply Ability | 1000kg per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Zirconium Carbide (ZrC) is a refractory ceramic material known for its hardness, high melting point, and chemical stability. It is commonly used in vacuum deposition techniques like thermal evaporation and electron-beam (e-beam) evaporation to create thin films, particularly in applications that demand durability, heat resistance, and wear protection. ZrC also exhibits metallic conductivity and is widely used for protective coatings in high-temperature environments.

Key Applications:

- Protective Coatings: Used in the production of wear-resistant and high-temperature protective coatings for tools, cutting instruments, and high-stress environments.

- Aerospace and Space Technologies: Ideal for components exposed to extreme heat and oxidation, such as those in aerospace engines, rocket nozzles, and thermal shields.

- Optical Coatings: Applied in thin films to protect optical components, especially those that must withstand harsh environmental conditions.

- Nuclear Applications: ZrC is used in nuclear reactors due to its high neutron absorption cross-section and ability to withstand extreme temperatures.

- Semiconductor Industry: Utilized for its conductive properties in certain semiconductor and microelectronic applications.

- Metal Matrix Composites: Used as a reinforcement material in metal matrix composites to enhance the properties of metal substrates.

Features:

- High Melting Point: ZrC has an extremely high melting point (~3,530°C), making it suitable for high-temperature applications.

- Excellent Hardness and Wear Resistance: It provides outstanding hardness, making it ideal for protective coatings and applications requiring high durability.

- Good Thermal and Electrical Conductivity: ZrC exhibits metallic-like conductivity, which is beneficial for electrical applications and high-heat environments.

- Corrosion and Oxidation Resistance: Highly resistant to chemical attack, corrosion, and oxidation, even in harsh conditions.

- Low Density: Compared to other refractory materials, ZrC has a relatively low density, making it advantageous in aerospace applications where weight is a critical factor.

Specifications:

- Material: Zirconium Carbide (ZrC)

- Purity: ≥ 99.5%

- Shape: Pellets

- Size: Typically 1-6 mm in diameter (custom sizes available)

- Melting Point: 3,530°C

- Density: 6.73 g/cm³

- Deposition Methods: Suitable for thermal evaporation, e-beam evaporation, and sputtering

- Applications: High-temperature coatings, wear protection, aerospace components, and semiconductor industries

Tinsan Materials offers high-purity ZrC (Zirconium Carbide) pellets for evaporation processes. Ideal for wear-resistant coatings, aerospace, and high-temperature applications. Suitable for thermal and e-beam evaporation.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.