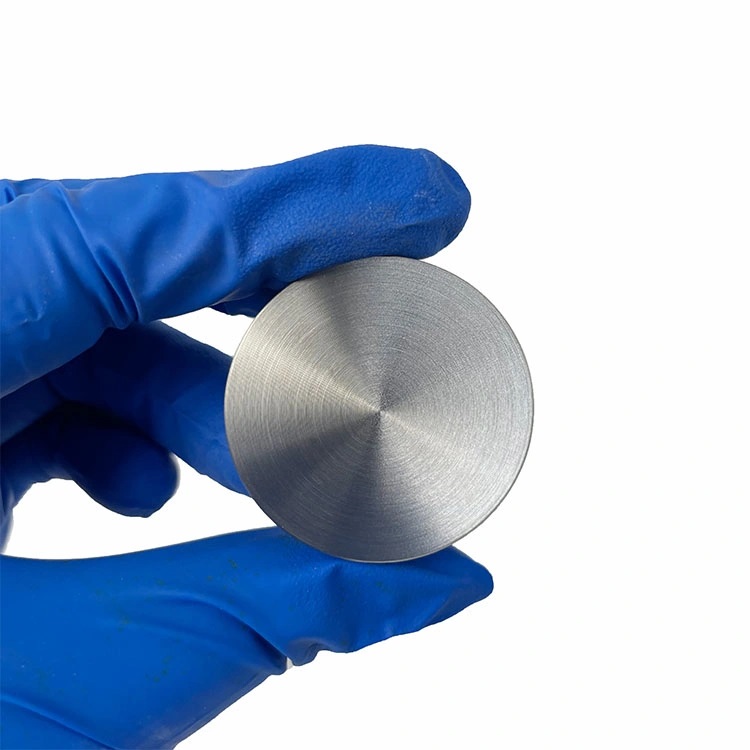

ZrC (Zirconium Carbide) Sputtering Target

- High Hardness: ZrC is known for its extreme hardness, which contributes to the durability and wear resistance of coatings.

- Excellent Thermal Conductivity: ZrC is highly conductive, making it suitable for thermal management applications.

- High Melting Point: ZrC’s melting point of approximately 3,540°C ensures that it performs well in high-temperature environments.

- Chemical Stability: ZrC films are resistant to oxidation and chemical corrosion, extending the lifespan of coated surfaces.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Material | ZrC |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Zirconium Carbide (ZrC) sputtering targets are used in thin film deposition for their unique properties, including high hardness, excellent thermal conductivity, and chemical stability. ZrC films are applied in industries such as aerospace, electronics, and cutting tools due to their high resistance to wear and heat.

Key Applications:

- Hard Coatings: ZrC is used in producing hard, wear-resistant coatings on cutting tools, providing enhanced durability and performance in extreme environments.

- Thermal Barrier Coatings: ZrC thin films are applied in aerospace and power generation industries as thermal barrier coatings due to their high melting point and thermal stability.

- Semiconductors: ZrC is also used in semiconductor devices, especially in high-temperature and high-wear applications.

- Abrasive and Protective Coatings: ZrC films protect surfaces from corrosion and wear in aggressive environments, making them useful for parts exposed to high stress and chemical exposure.

- High-Temperature Structural Materials: In aerospace and defense, ZrC is valuable for components that operate at elevated temperatures due to its exceptional thermal stability.

Features of ZrC Sputtering Targets:

- High Hardness: ZrC is known for its extreme hardness, which contributes to the durability and wear resistance of coatings.

- Excellent Thermal Conductivity: ZrC is highly conductive, making it suitable for thermal management applications.

- High Melting Point: ZrC’s melting point of approximately 3,540°C ensures that it performs well in high-temperature environments.

- Chemical Stability: ZrC films are resistant to oxidation and chemical corrosion, extending the lifespan of coated surfaces.

Customization Options:

- Target Sizes and Shapes: ZrC targets are available in various dimensions to suit different sputtering systems.

- Purity Levels: High-purity ZrC sputtering targets ensure the production of high-quality, defect-free thin films.

- Bonding Options: ZrC targets can be bonded to backing plates for enhanced performance and thermal management during sputtering.

ZrC (Zirconium Carbide) sputtering targets from Tinsan Materials offer high hardness, thermal conductivity, and chemical stability for thin film deposition. Ideal for hard coatings, thermal barriers, and semiconductor applications, ZrC targets are available in various sizes and purity levels for industrial use.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.