ZrO2 (Zirconium Dioxide) Sputtering Target

- High Refractive Index: ZrO₂ has a high refractive index, making it ideal for optical coatings where enhanced light control and reflection properties are needed.

- Dielectric Properties: ZrO₂ exhibits a high dielectric constant, which is critical for its use in electronic and semiconductor applications.

- Thermal Stability: ZrO₂ can withstand extreme temperatures, making it suitable for use in high-temperature coatings and thermal barrier applications.

- Wear Resistance: ZrO₂ films provide excellent hardness and wear resistance, extending the life of coated components in industrial and aerospace environments.

- Corrosion Resistance: The chemical inertness of ZrO₂ makes it resistant to corrosion, which is important in applications exposed to harsh chemicals or environmental conditions.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

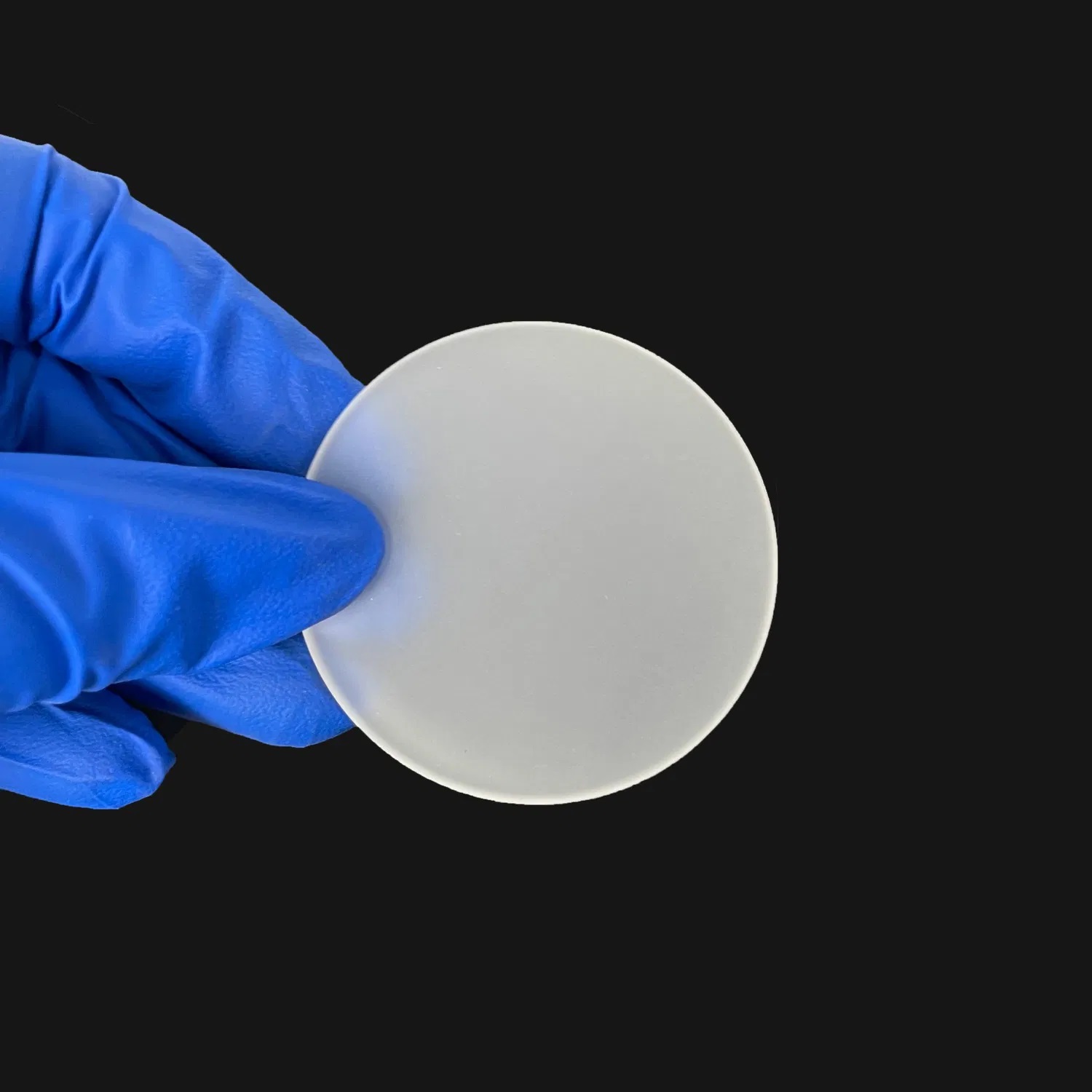

| Material | ZrO2 |

| Purity | 99.9% – 99.9999% / 3N 3N5 4N 4N5 5N 5N5 6N |

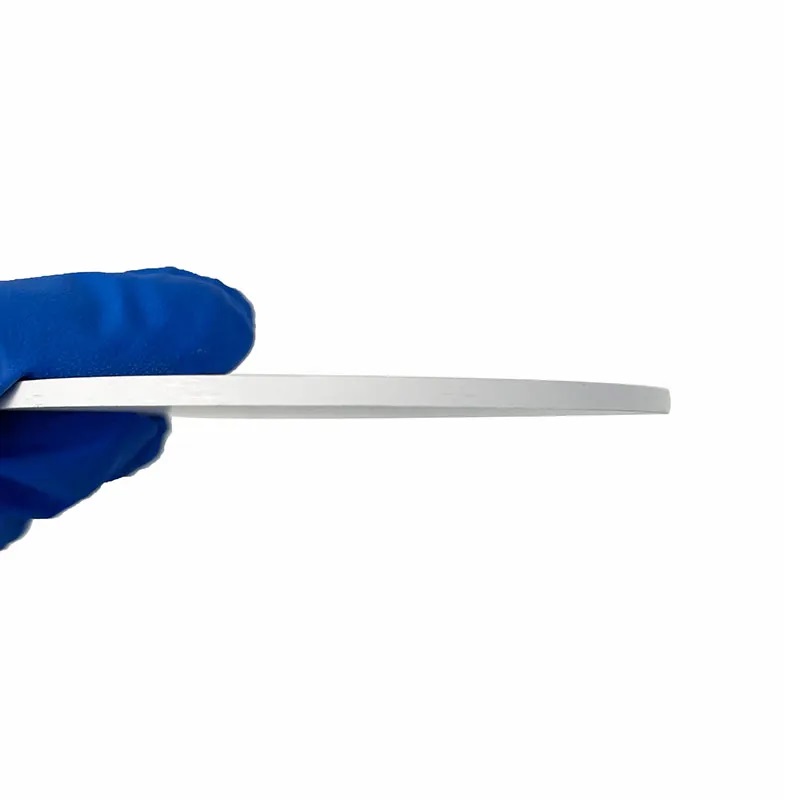

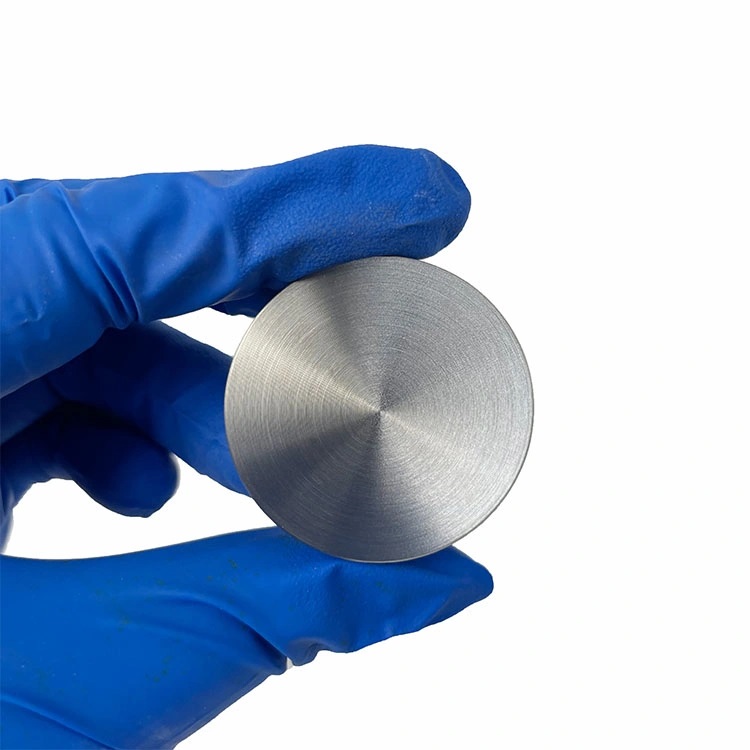

| Shape | disc, plate, sheet, rod, customized |

| Size | can be customized (contact us) |

| Package | vacuum bag or customer’s request |

| Place of Origin | China |

| MOQ | 1pcs |

| Supply Ability | 10000pcs per month |

| Lead Time | Qty: 1-100, Time: 3-10 days

Qty: >100, Time: to be negotiated |

Zirconium dioxide (ZrO₂), also known as zirconia, is widely used for sputtering targets in thin-film deposition due to its excellent mechanical, thermal, and dielectric properties. ZrO₂ is highly valued in various advanced applications, including electronics, optical coatings, and protective films, owing to its high hardness, chemical inertness, and thermal stability.

Key Applications:

- Optical Coatings: ZrO₂ thin films are used in optical coatings for lenses, mirrors, and display screens due to their high refractive index and transparency in the visible and near-infrared regions. They provide durability and scratch resistance in optical components.

- Semiconductor Industry: ZrO₂ is used in semiconductor devices as an insulating layer or dielectric material due to its high dielectric constant. It is often applied in gate dielectrics, capacitors, and other microelectronic components.

- Thermal Barrier Coatings: ZrO₂ is commonly applied as a thermal barrier coating (TBC) in high-temperature environments such as turbine blades, engines, and industrial equipment. It provides excellent heat resistance and protects components from thermal damage.

- Protective Coatings: Thin films of ZrO₂ are used as protective layers in harsh environments due to their high wear resistance, chemical inertness, and corrosion resistance.

- Biomedical Applications: ZrO₂ films are used in biomedical devices and implants due to their biocompatibility and high mechanical strength. They are often applied as coatings on dental implants, artificial joints, and other medical devices.

- Sensors: ZrO₂ thin films are employed in gas sensors, particularly oxygen sensors, due to their ionic conductivity and stability at high temperatures.

Features of ZrO₂ Sputtering Targets:

- High Refractive Index: ZrO₂ has a high refractive index, making it ideal for optical coatings where enhanced light control and reflection properties are needed.

- Dielectric Properties: ZrO₂ exhibits a high dielectric constant, which is critical for its use in electronic and semiconductor applications.

- Thermal Stability: ZrO₂ can withstand extreme temperatures, making it suitable for use in high-temperature coatings and thermal barrier applications.

- Wear Resistance: ZrO₂ films provide excellent hardness and wear resistance, extending the life of coated components in industrial and aerospace environments.

- Corrosion Resistance: The chemical inertness of ZrO₂ makes it resistant to corrosion, which is important in applications exposed to harsh chemicals or environmental conditions.

Customization Options:

- Target Sizes: ZrO₂ sputtering targets are available in different shapes and sizes, including planar and rotary configurations, to fit various deposition systems.

- Purity Levels: High-purity zirconium dioxide targets (up to 99.999%) are available to ensure optimal thin-film quality and performance.

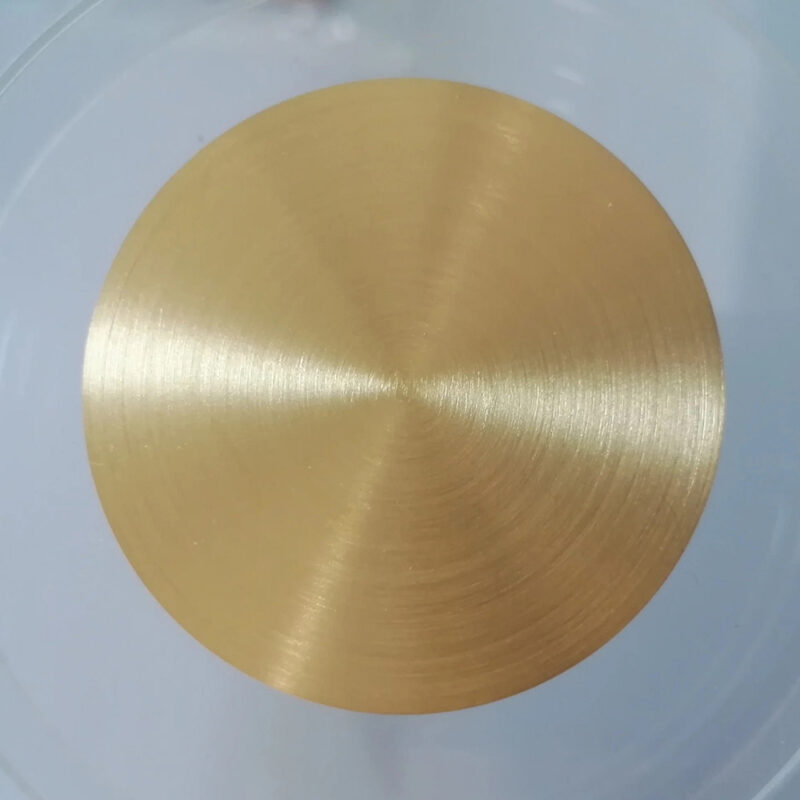

- Target Bonding: ZrO₂ sputtering targets can be bonded to backing plates to improve thermal conductivity and prevent target cracking during sputtering.

ZrO₂ (Zirconium Dioxide) sputtering targets from Tinsan Materials are used in thin-film deposition for optical coatings, semiconductors, thermal barriers, and protective applications. High-purity ZrO₂ targets provide superior wear resistance, thermal stability, and high dielectric properties, customizable to specific requirements.

If you have specific requirements, such as dimensions, purity, or application details, please contact us to match your needs.