Showing 145–156 of 632 results

-

- Excellent thermal conductivity for rapid and even heating

- Suitable for metals with lower melting points and temperature-sensitive processes

- Versatile shapes and customizable sizes available for diverse applications

- High electrical conductivity for electrochemical processes

-

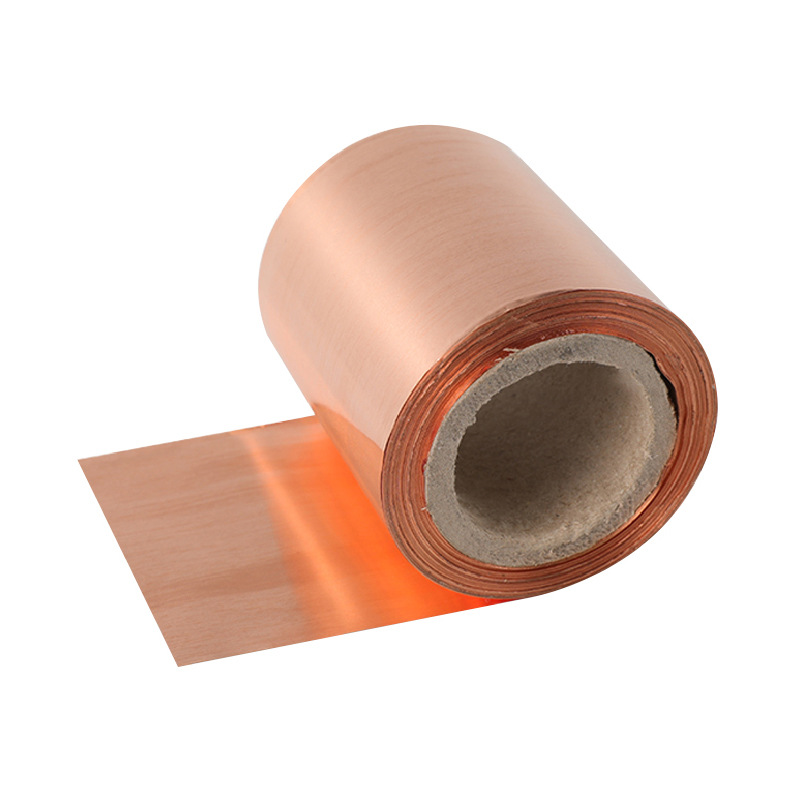

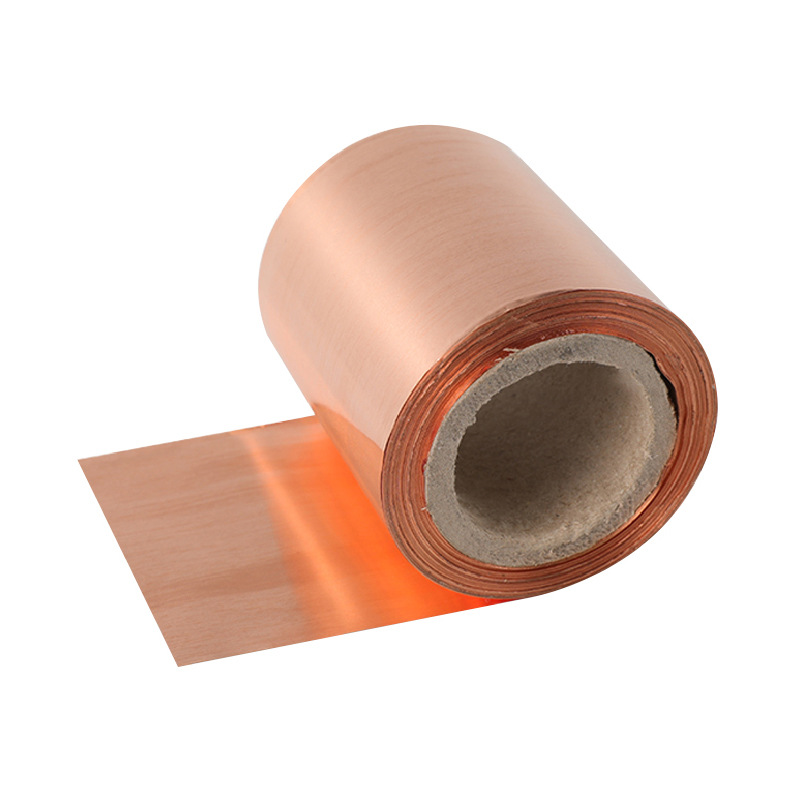

- High Electrical Conductivity: Copper foil is known for its excellent electrical conductivity, making it ideal for use in electrical and electronic applications. It allows the efficient flow of electrical current with minimal resistance, which is crucial in devices like circuit boards, power systems, and transformers.

- Thermal Conductivity: Copper is one of the best materials for heat conduction. Copper foil efficiently dissipates heat, making it essential in applications such as heat sinks, thermal management, and cooling systems.

- Corrosion Resistance: Copper foil naturally forms a protective oxide layer on its surface, which helps resist corrosion, especially in environments exposed to moisture or chemicals. This makes copper foil durable and suitable for a range of industrial applications.

- Malleability and Ductility: Copper foil is highly malleable and can be easily formed into various shapes and sizes without cracking. This flexibility allows for diverse uses in manufacturing, especially for flexible printed circuits and various packaging applications.

- Lightweight: Copper foil is lightweight, making it easy to handle and transport. Despite its lightness, it maintains excellent mechanical strength and durability, making it an attractive option for many industries that require both strength and weight reduction.

- Recyclability: Copper is 100% recyclable without losing its properties. This makes copper foil an environmentally friendly choice, as it can be reused multiple times, reducing waste and supporting sustainable practices.

-

$10.00 – $240.00

- High Purity: Copper pellets for evaporation are available in purity levels of 99.99% (4N) and above, ensuring that the thin films produced are of the highest quality and free from impurities.

- Uniformity: The spherical shape of copper pellets promotes even melting and vaporization during the deposition process, resulting in uniform thin films.

- Compatibility: Copper is compatible with a range of substrates, including glass, metals, and semiconductors, making it versatile for various thin film applications.

- High Conductivity: Copper films exhibit excellent electrical and thermal conductivity, enhancing performance in electronic and thermal management applications.

-

- High Electrical and Thermal Conductivity: Ideal for electronic and heat transfer applications.

- High Purity: Minimal impurities to ensure reliable performance.

- Customizable Particle Sizes: Available in nano, micro, and spherical forms for versatile uses.

- Corrosion Resistance: Resistant to oxidation and environmental factors.

- Superior Sintering Properties: Enhances bonding and structural strength in metallurgical applications.

-

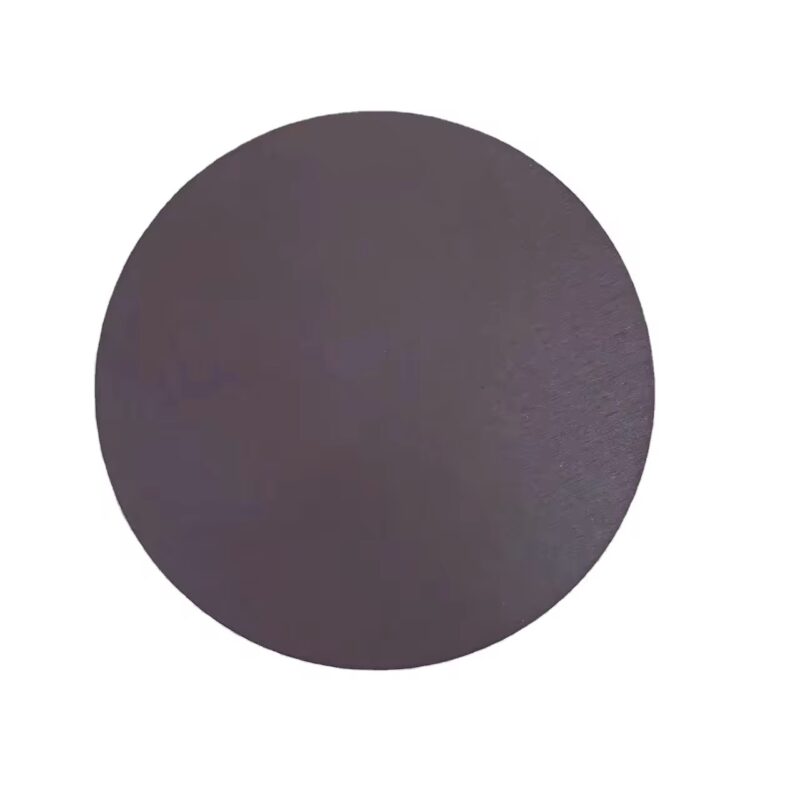

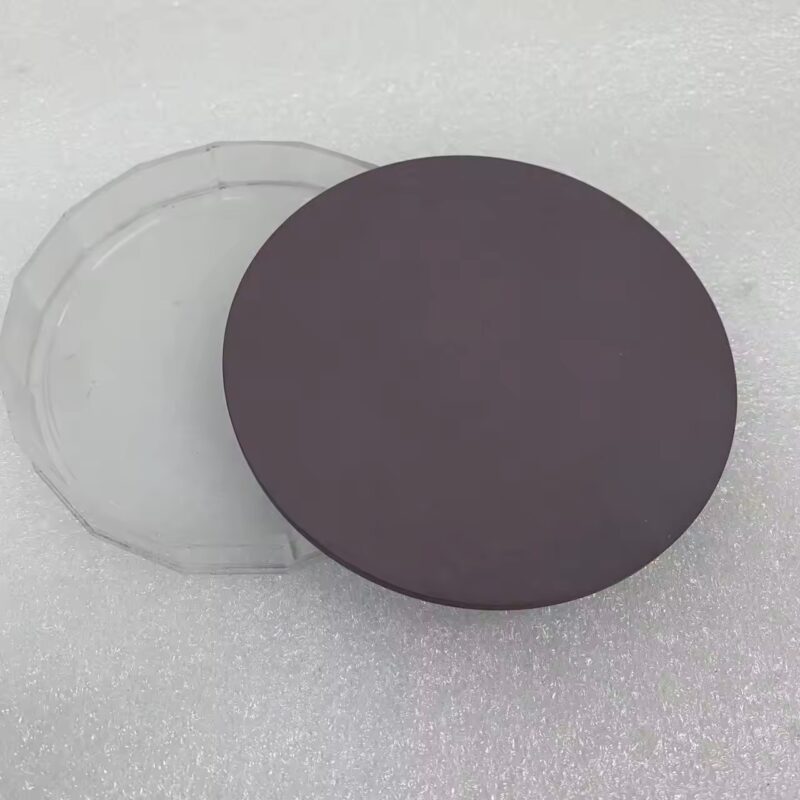

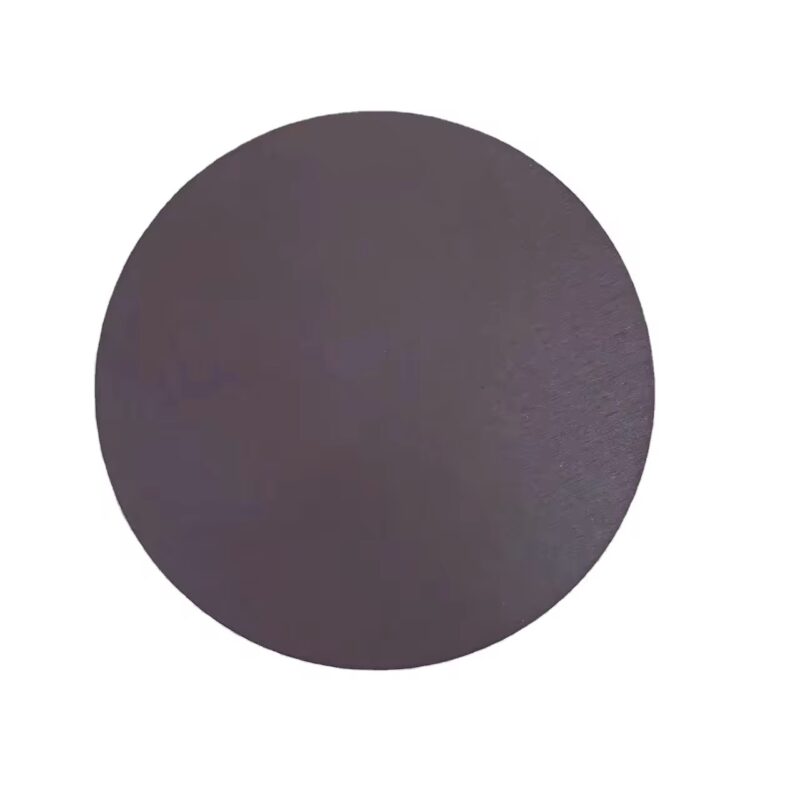

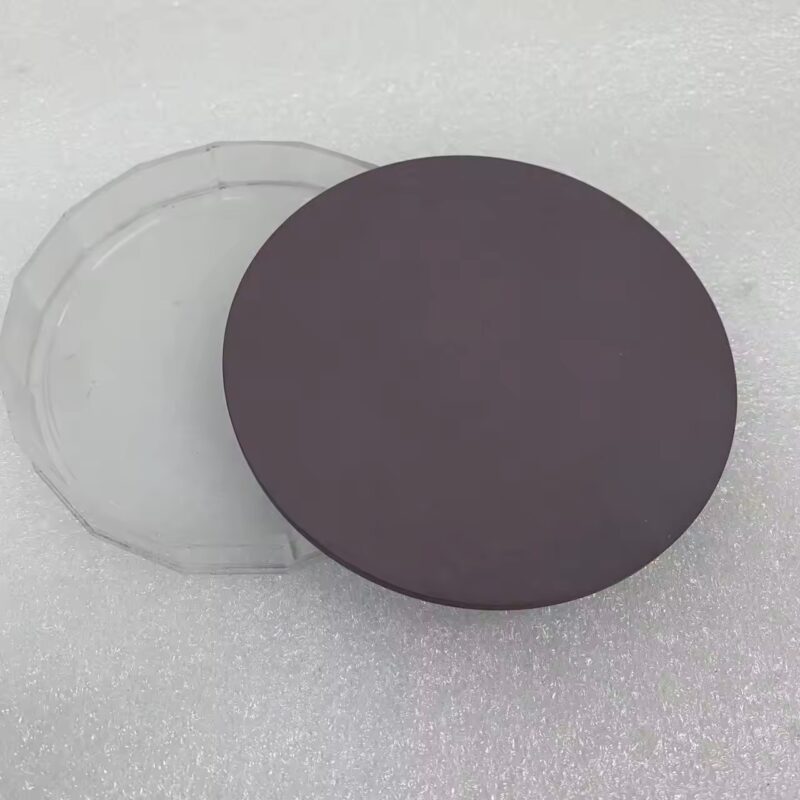

Copper (Cu) is highly valued for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it a key material in a variety of industries, including electronics, semiconductors, and energy. Copper (Cu) sputtering targets are essential for industries that require highly conductive, thermally efficient, and corrosion-resistant coatings, making them indispensable in electronics, semiconductors, energy, and decorative applications.

-

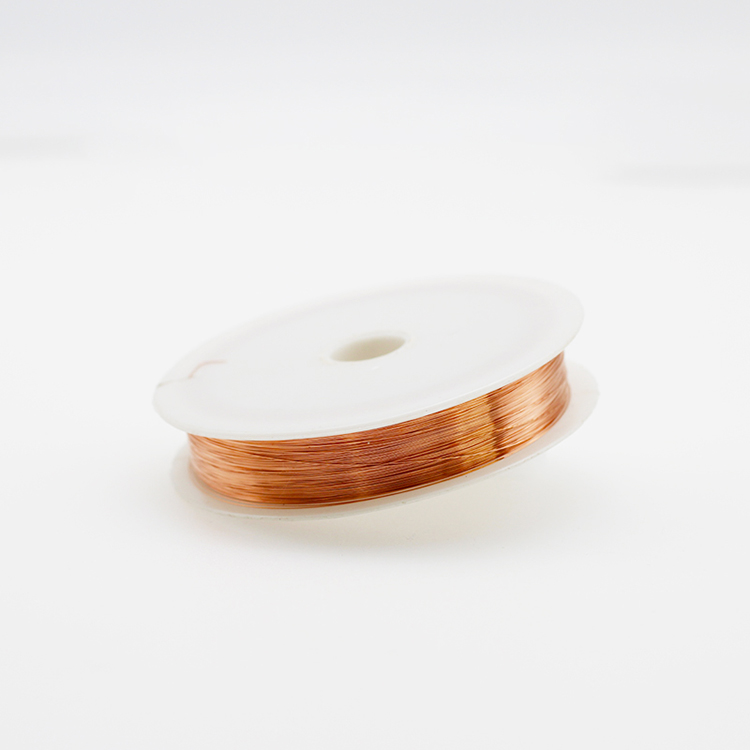

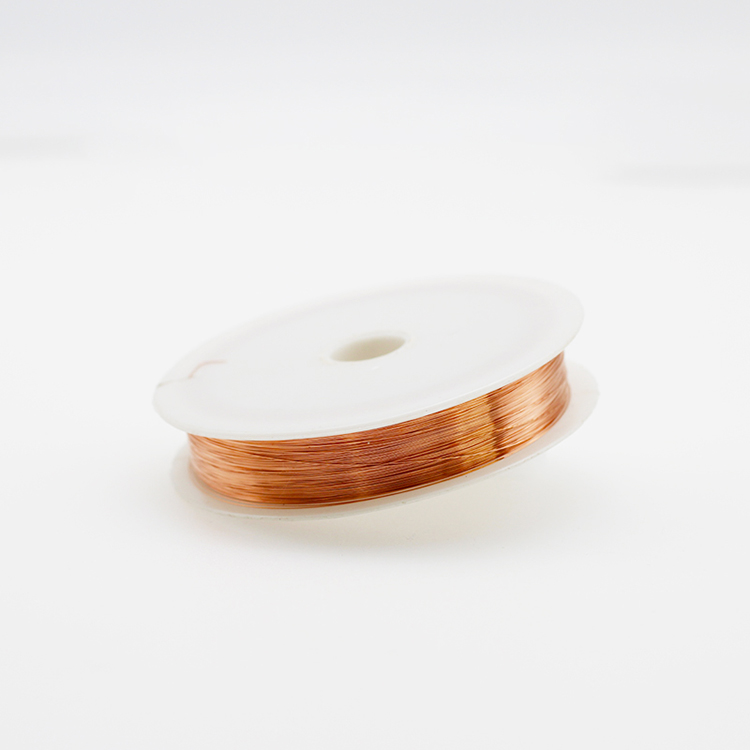

- High Electrical Conductivity: Copper wire is renowned for its excellent electrical conductivity, second only to silver. This makes it ideal for use in electrical wiring and applications that demand efficient energy transfer.

- Malleability and Ductility: Copper wire is highly malleable and ductile, which allows it to be drawn into thin wires without breaking. This makes it versatile and suitable for various applications, especially in intricate and delicate designs.

- Corrosion Resistance: Copper naturally forms a protective oxide layer when exposed to air, which helps resist corrosion and ensures long-lasting performance, especially in outdoor and marine environments.

- Thermal Conductivity: Copper has high thermal conductivity, making it ideal for heat dissipation applications in electronic devices and power transmission.

- Strength and Durability: Copper wire is durable and resilient to physical stress, making it a reliable material for long-term use in cables and machinery.

- Recyclability: Copper is 100% recyclable without losing its original properties, making it an environmentally friendly choice for sustainable manufacturing processes.

-

- High Purity: Superior-grade material ensuring reliable performance.

- Photocatalytic Efficiency: Excellent for light-driven chemical reactions.

- Thermal and Electrical Conductivity: Supports applications in energy and electronics.

- Environmentally Friendly: Non-toxic and sustainable material.

- Customizable Specifications: Tailored particle sizes and packaging to meet diverse needs.

-

- High purity (≥99.9% or ≥99.99%).

- Exceptional chemical and thermal stability.

- Uniform pellet size for consistent performance.

- Customizable specifications to meet application requirements.

-

- Semiconductor Properties: Cu₂O is a p-type semiconductor with a direct bandgap, making it ideal for optoelectronic applications like solar cells and sensors.

- High Purity: High-purity Cu₂O sputtering targets are available to ensure efficient and precise deposition of thin films with minimal impurities.

- Environmentally Friendly: Cu₂O is a non-toxic, earth-abundant material, which makes it a sustainable choice for eco-friendly applications, especially in solar energy.

- Cost-effective: Compared to other materials, Cu₂O is affordable, making it attractive for large-scale applications such as photovoltaic cells.

-

- Semiconductor Properties: Cu₂S has p-type semiconductor properties, making it suitable for various electronic and photovoltaic applications.

- Good Optical Absorption: Cu₂S efficiently absorbs light, especially in the visible and near-infrared regions, making it ideal for solar cell applications.

- High Conductivity: Cu₂S exhibits good electrical conductivity, which is useful in applications that require conductive thin films.

- Thermal and Chemical Stability: Copper(I) Sulfide is thermally stable and resistant to certain chemicals, ensuring durability in harsh environments.

-

- High Optical Absorption: Cu2S exhibits strong absorption in the visible and near-infrared regions, making it effective for light-harvesting devices like solar cells.

- Good Semiconductor Properties: Copper(I) Sulfide has favorable electrical properties that make it a valuable material for semiconductors and related electronic devices.

- Thermal Stability: The material maintains stability at high evaporation temperatures, ensuring high-quality thin films in evaporation processes.

- High Purity: Available in high purity, ensuring minimal contamination and consistent thin film deposition for sensitive applications.

-

- High Purity: Ensures reliable performance in sensitive applications.

- Semiconducting Properties: Ideal for photovoltaic and electronic devices.

- Thermal Stability: Maintains properties at elevated temperatures.

- Customizable Particle Sizes: Nano and micron-sized powders for specific needs.

- Eco-friendly: Suitable for green energy applications.

- Wide Application Range: Useful in electronics, catalysis, and sensors.