Showing 181–192 of 632 results

-

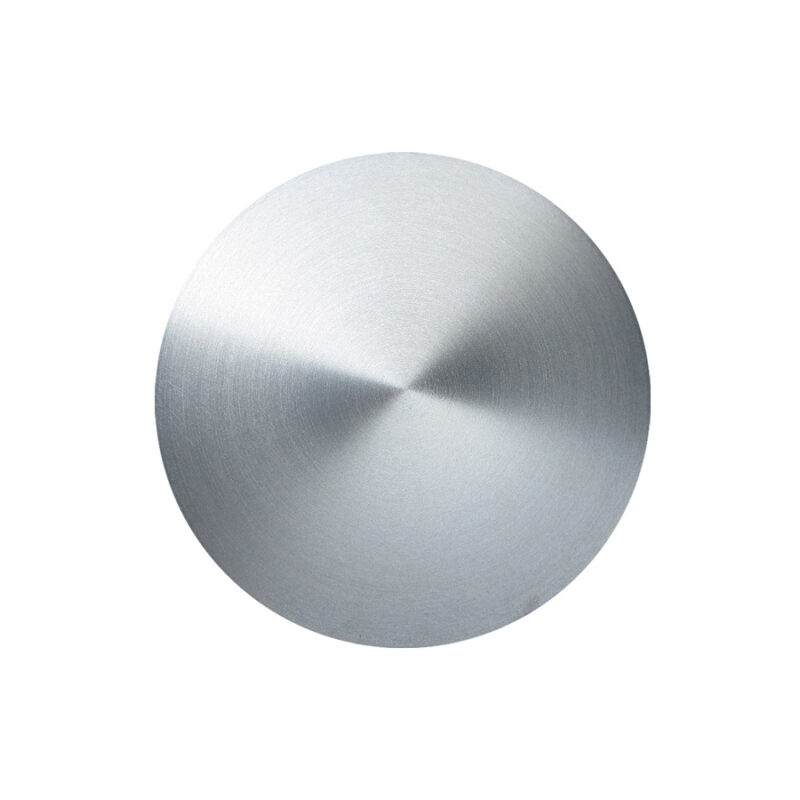

- Material: High-purity Erbium, typically with a purity level of 99.9% (3N) or higher, ensures minimal impurities during the sputtering process.

- Form: Erbium sputtering targets are commonly available in the form of discs, rectangular plates, or custom shapes, depending on specific application requirements.

- Density: The target’s density is critical for achieving consistent deposition rates and high-quality thin films.

- Applications: These targets are used in applications such as optical amplifiers, lasers, telecommunications, and electronic devices.

-

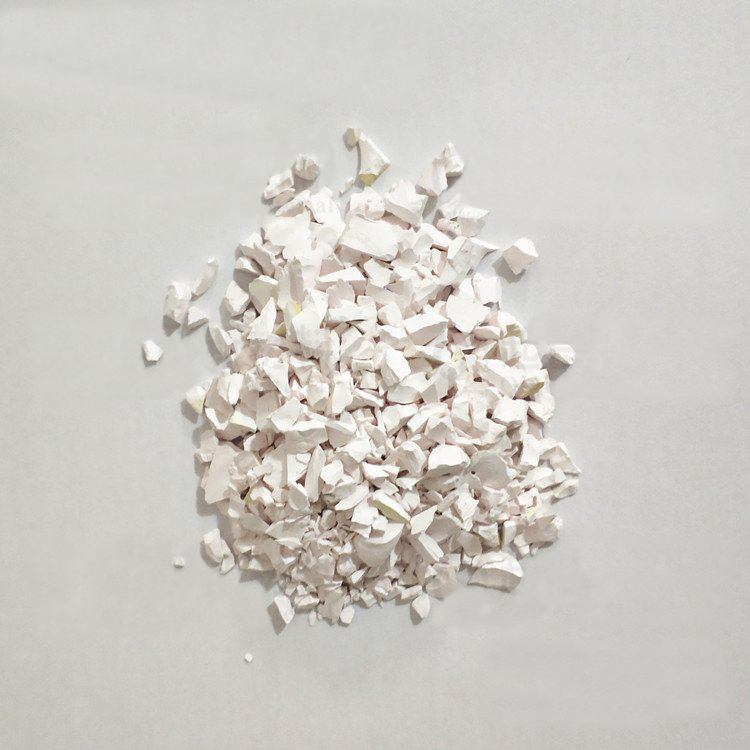

- High purity (≥99.9%).

- Outstanding thermal and chemical stability.

- Superior optical properties for infrared applications.

- Uniform pellet size for reliable thin-film deposition.

- Customizable specifications to meet specific requirements.

-

- High Purity: Guarantees consistent performance in specialized applications.

- Unique Optical Properties: Displays excellent fluorescence in infrared regions.

- Thermal Stability: Retains structural integrity at high temperatures.

- Low Phonon Energy: Ideal for laser and optical amplification.

- Versatile Applications: Suited for ceramics, glass, and optical devices.

-

- High Infrared Transparency: Er₂O₃ has excellent transparency in the infrared range, making it a critical material for fiber-optic communications, laser systems, and IR detectors.

- Optical Amplification: The presence of erbium ions in Er₂O₃ allows for efficient optical amplification in the telecommunications band around 1.55 µm, making it ideal for use in EDFAs.

- Thermal Stability: Er₂O₃ sputtering targets provide thin films that are thermally stable and chemically inert, suitable for high-temperature applications.

- Customizability: Er₂O₃ sputtering targets can be customized to meet specific deposition needs, including different geometries, sizes, and purity levels for improved thin-film performance.

-

- Luminescent Properties: Europium is known for its strong luminescent behavior, especially its red and blue emissions, making it a crucial element in display and lighting applications.

- Magnetic Behavior: Europium exhibits unique magnetic properties useful in advanced research, magnetic refrigeration, and specific data storage applications.

- High Thermal Stability: Europium offers high stability at elevated temperatures, suitable for use in high-temperature deposition processes like e-beam and thermal evaporation.

-

- Strong Luminescence: Eu₂O₃ is widely recognized for its luminescent properties, particularly its emission in the red spectrum, making it ideal for use in display technologies and lighting.

- Stable Thin Films: Europium oxide thin films provide excellent chemical stability and durability, ensuring long-lasting performance in devices exposed to various environmental conditions.

- Optical Transparency: Eu₂O₃ exhibits good optical transparency in specific wavelengths, enhancing its performance in optical applications, from phosphors to light-emitting devices.

- High Purity: High-purity Eu₂O₃ targets (up to 99.99%) ensure optimal performance in thin-film deposition processes, especially in high-tech applications such as displays and optoelectronics.

-

- High purity (≥99.9%).

- Excellent optical and luminescent properties.

- Uniform pellet size for consistent deposition results.

- Customizable dimensions to meet application needs.

- Stable chemical and structural characteristics.

-

- High Purity: Ensures reliable performance in critical applications.

- Superior Luminescence: Ideal for phosphors in displays and lighting.

- Thermal Stability: Suitable for high-temperature applications.

- Customizable Particle Sizes: Available in nano and micron scales.

- Versatile Applications: Supports electronics, ceramics, and R&D needs.

- Rare-earth Advantage: A unique material for high-performance industries.

-

- Strong Luminescence: Europium pentoxide exhibits intense red luminescence, which is particularly useful in display and lighting technologies.

- High Purity: Typically available at high purity levels (≥ 99.9%) to ensure optimal performance in high-precision applications, such as thin-film deposition.

- Thermal Stability: Eu2O5 is stable at high temperatures, making it suitable for vacuum evaporation processes, including e-beam evaporation.

- Consistent Film Quality: Due to its stable evaporation characteristics, Eu2O5 produces consistent thin films ideal for high-tech optical and electronic applications.

-

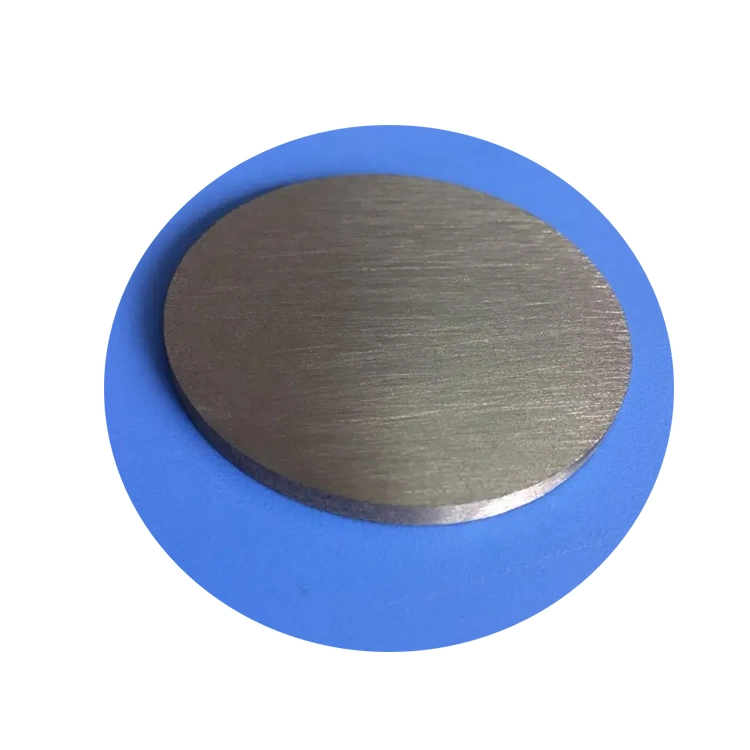

- Superior Performance in Electromagnetic Applications: The high magnetic permeability of high purity iron makes it an ideal material for manufacturing electromagnetic components such as inductors, transformers, and magnetic shielding.

- Enhanced Material Properties: The minimal presence of impurities in high purity iron improves its mechanical properties, such as ductility, tensile strength, and fatigue resistance, making it more reliable in demanding applications.

- Improved Durability: The high purity of iron ensures that it is less susceptible to failure due to impurities, offering longer-lasting performance in industrial and technological applications.

- Customization: High purity iron wire can be tailored to specific requirements, such as wire gauge, length, and coatings, for specialized applications in different industries.

- High Precision and Consistency: The uniformity of high purity iron ensures that it performs consistently in precision applications, where small variations in material properties can lead to failure.

- Cost-Effectiveness: While high purity iron wire may have a slightly higher initial cost than standard iron wire, its superior performance and longer lifespan make it a cost-effective choice in the long run, especially for advanced applications.

-

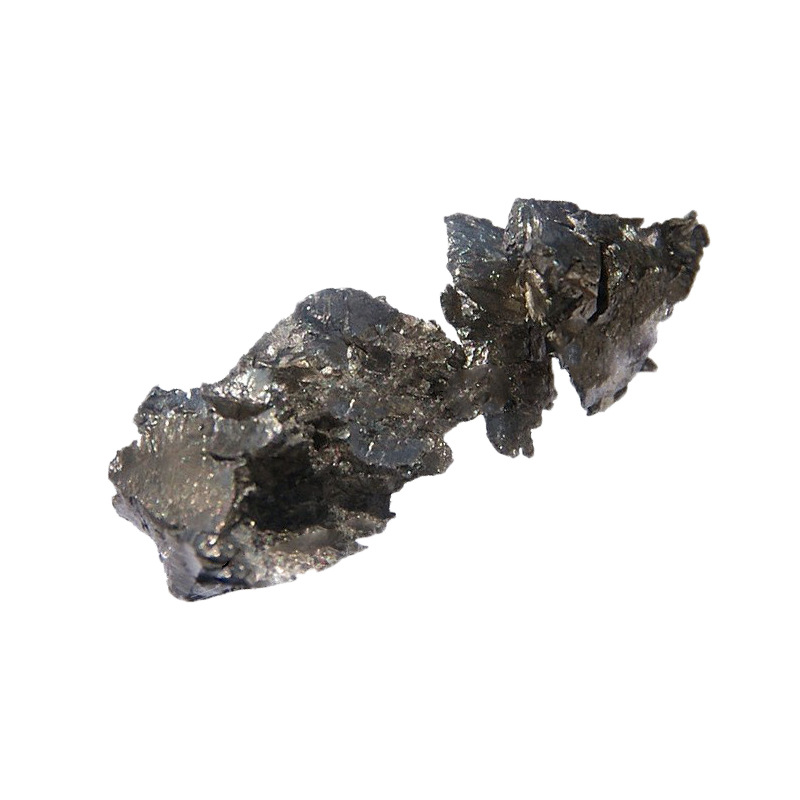

Iron (Fe Ferrum) sputtering targets are essential for industries that rely on the unique magnetic, electrical, and structural properties of iron, making them indispensable in magnetic storage, electronics, industrial coatings, and advanced material applications.

-

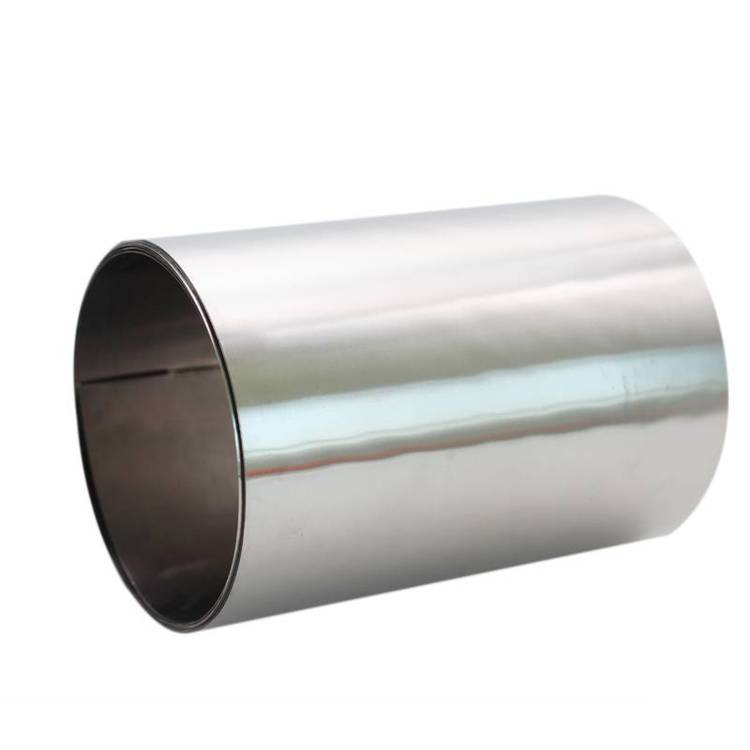

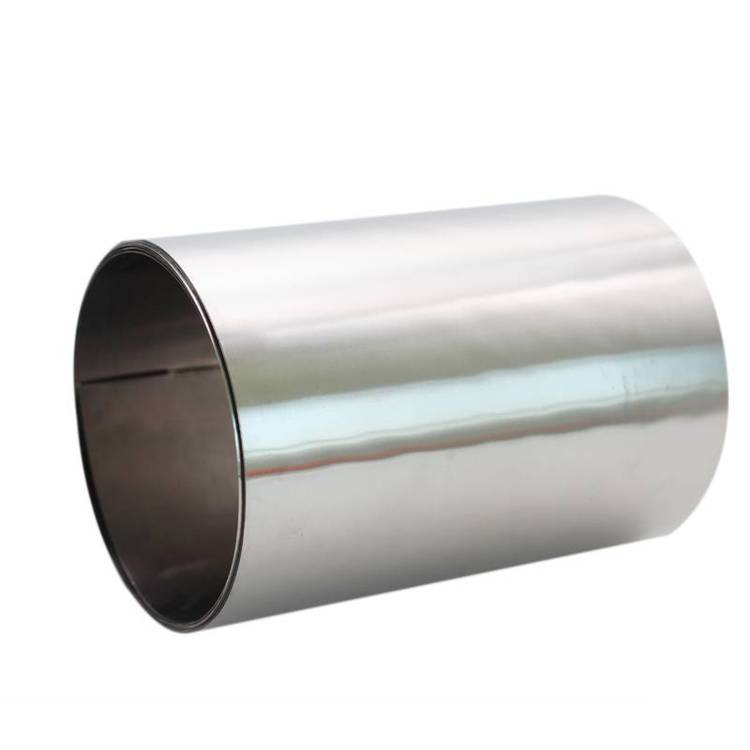

- Magnetic Properties: Iron foil possesses strong magnetic properties, making it essential for use in applications involving electromagnetism, such as transformers and electric motors.

- Strength and Durability: Iron foil is known for its strength and ability to withstand mechanical stresses, ensuring durability in industrial applications.

- Malleability and Flexibility: Iron foil is highly malleable and flexible, allowing it to be easily shaped into thin sheets, making it adaptable for various applications.

- Corrosion Resistance: While iron is generally prone to oxidation, specially treated iron foil can exhibit excellent resistance to corrosion and rust, increasing its longevity.

- Thermal Conductivity: Iron foil has moderate thermal conductivity, making it suitable for applications that require heat distribution.

- Low Cost: Iron foil is cost-effective compared to other metallic foils like gold or silver, making it an affordable solution for various applications.