Showing 397–408 of 632 results

-

- Narrow Bandgap: PbS has a small bandgap (~0.37 eV), allowing it to detect and respond to IR radiation, making it ideal for infrared applications.

- High Infrared Sensitivity: PbS thin films exhibit excellent sensitivity to infrared light, especially in the mid-IR range, enhancing performance in IR detectors and sensors.

- Efficient Light Absorption: PbS absorbs light efficiently, making it a great material for photovoltaic devices and optoelectronic components.

- Good Thermal Stability: PbS films maintain their properties under moderate temperature conditions, suitable for use in thermal and IR-sensitive devices.

- Adaptability to Thin Films: PbS can be easily deposited as a thin film via evaporation, making it suitable for creating highly sensitive IR detectors and optical coatings.

-

- Narrow Bandgap Semiconductor: PbTe has a bandgap of approximately 0.32 eV, which enables high sensitivity to infrared radiation in the 3-5 µm range.

- High Thermoelectric Efficiency: PbTe has excellent thermoelectric properties, making it suitable for energy conversion in both power generation and refrigeration applications.

- Good Thermal and Electrical Conductivity: PbTe exhibits strong thermal and electrical conductivity, essential for efficient thermoelectric devices and IR detection systems.

- Infrared Absorption: PbTe is highly effective at absorbing infrared light, particularly in the mid-IR region, making it ideal for infrared detectors and optoelectronic devices.

- Thin Film Deposition: PbTe can be deposited as a uniform thin film through evaporation techniques, ensuring high performance in electronic and optoelectronic applications.

-

- Thermoelectric Efficiency: Exceptional thermoelectric properties for energy conversion and cooling applications.

- High Purity: ≥99.9% purity available, ensuring minimal impurities and high-quality performance.

- High Stability: Stable under both high and low temperatures, making it ideal for use in diverse temperature environments.

- Customizable Particle Size: Available in a range of particle sizes from nano to micro, suitable for various processing needs.

- Environmentally Friendly: PbTe is non-toxic and can be utilized in energy harvesting solutions, promoting sustainability.

- Versatile Application: Can be used in thermoelectric generators (TEGs) and thermoelectric coolers (TECs).

-

- High Purity: Up to 99.99% for superior film quality.

- Customizable Dimensions: Available in various sizes and shapes to fit specific equipment.

- Excellent Performance: Delivers consistent and uniform thin films.

- Thermoelectric and IR Applications: Suitable for deposition in advanced electronics and sensor systems.

-

- High Purity: Palladium pellets are available with purity levels of 99.95% (3N5) or higher, ensuring high-quality thin films with minimal impurities.

- Catalytic Properties: Palladium is highly valued for its catalytic activity, particularly in chemical reactions involving hydrogen.

- Corrosion Resistance: Palladium thin films offer excellent resistance to corrosion, making them suitable for applications in harsh environments.

- Electrical Conductivity: Palladium’s superior conductivity makes it ideal for use in electronic and semiconductor applications.

- Durability: Palladium coatings are long-lasting and resistant to wear, providing reliable performance in demanding applications.

-

- Outstanding Catalytic Properties: Palladium is an efficient catalyst in various industrial processes, especially in automotive emissions control and chemical production.

- High Electrical Conductivity: Suitable for electronic components that require stable and reliable performance.

- Corrosion Resistance: Palladium resists oxidation and corrosion, even at high temperatures.

- Hydrogen Absorption: Unique ability to absorb hydrogen, utilized in hydrogen storage and purification systems.

-

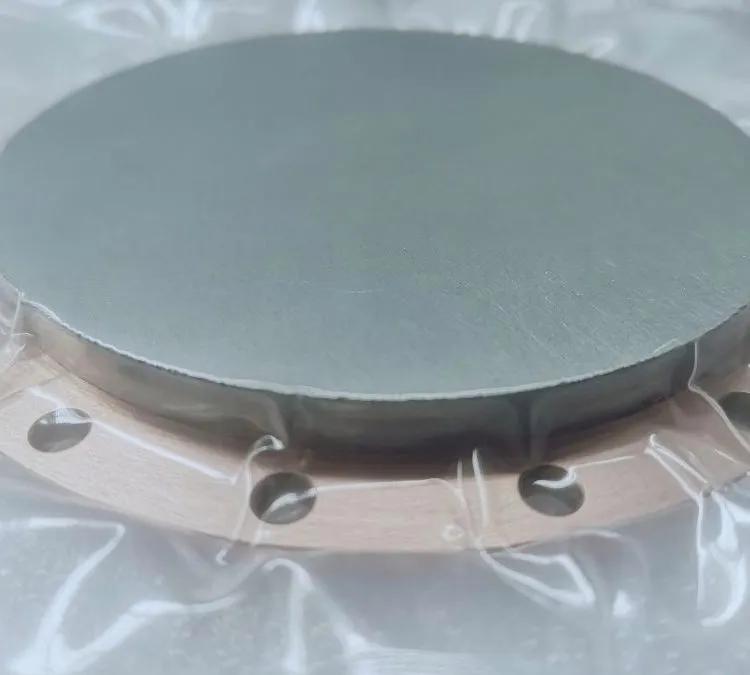

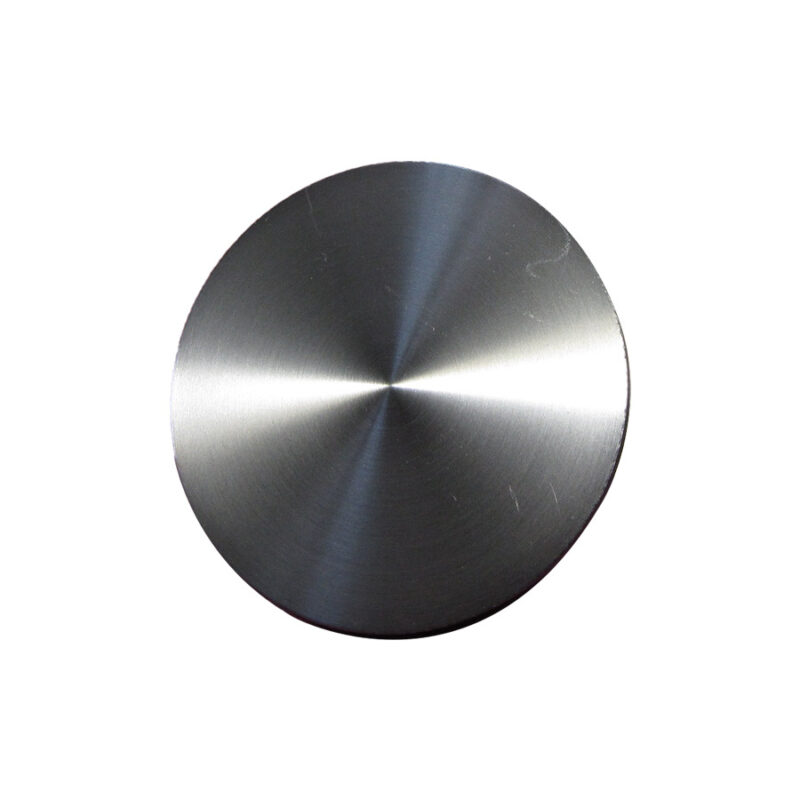

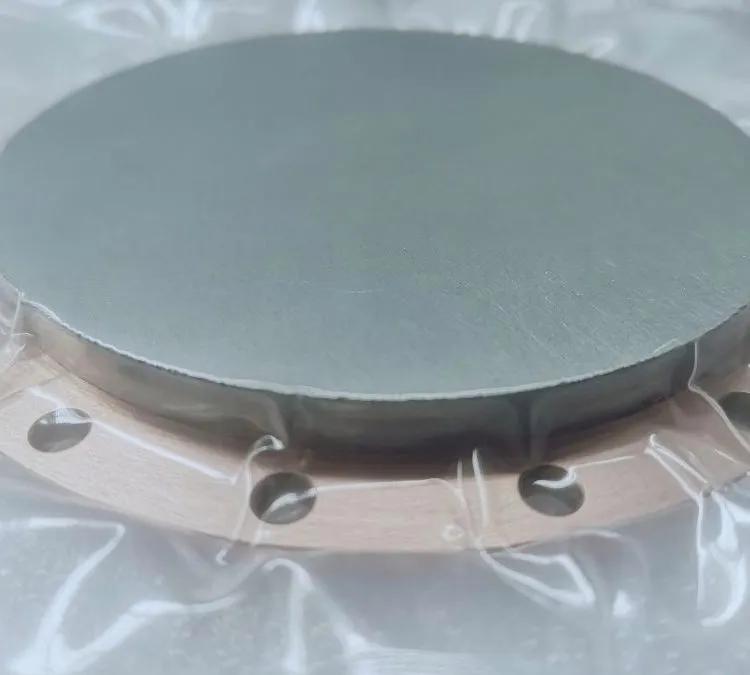

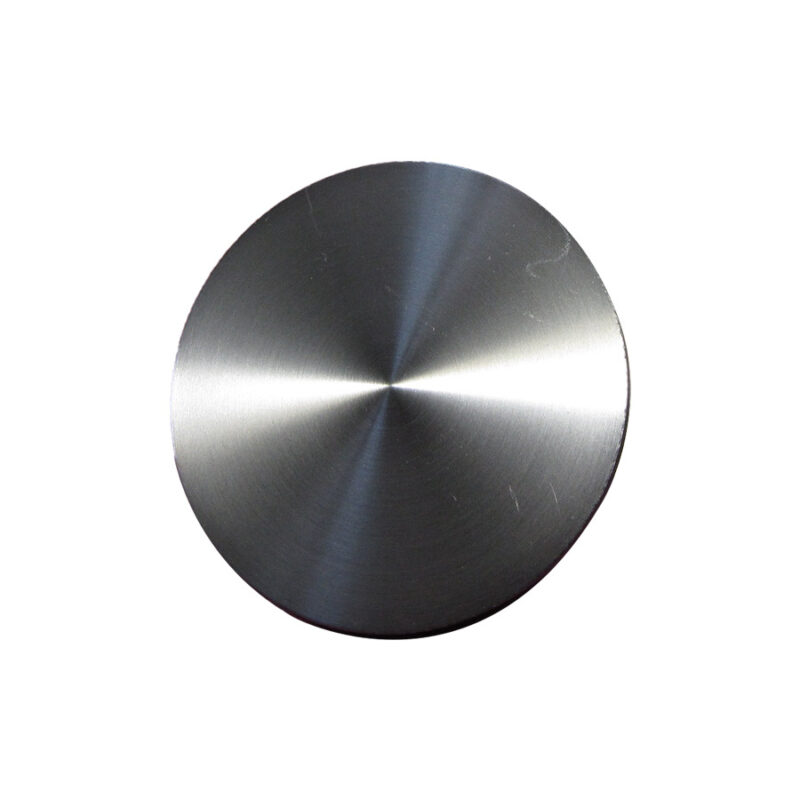

Palladium (Pd) sputtering targets are widely used in physical vapor deposition (PVD) processes to create thin films and coatings for various high-tech applications. Palladium, a precious metal in the platinum group, is known for its excellent catalytic properties, high conductivity, and strong resistance to corrosion and oxidation.

-

- High Purity: Praseodymium pellets are typically available at a purity level of 99.9% or higher, ensuring the quality of deposited thin films.

- Excellent Magnetic and Optical Properties: Praseodymium has favorable magnetic and optical properties, making it ideal for applications in optical devices and electronics.

- Thermal Stability: Praseodymium thin films demonstrate good stability under high temperatures, suitable for use in high-performance environments.

- Versatility in Applications: From optics to electronics, Praseodymium is versatile and can be integrated into a range of advanced technological applications.

-

Praseodymium sputtering targets are essential for creating thin films with specialized magnetic, optical, and electrical properties, making them valuable in advanced technological applications such as permanent magnets, lasers, display technologies, and specialized alloys. Despite its rarity, praseodymium’s unique characteristics offer significant benefits in cutting-edge industrial and scientific applications.

-

- High Purity: Available in high-purity forms (typically ≥ 99.9%), ensuring the quality and consistency of the deposited films in sensitive optical and electronic applications.

- Excellent Optical Properties: Pr6O11 provides reliable performance in optical films, contributing to the modulation of light in various optical components.

- Thermal and Chemical Stability: Its stability at high temperatures makes it a suitable material for thermal evaporation and other vacuum deposition methods.

- Versatile Applications: Pr6O11 pellets are used across multiple industries, including electronics, optics, ceramics, and catalysis.

-

$1.00

- Material Purity: ①Made from high-purity platinum (typically ≥ 99.95%). ②Can be alloyed with rhodium or iridium for enhanced durability.

- Thermal Stability: ①Excellent performance under high temperatures, withstanding up to 1,700°C without deformation. ②High melting point of platinum (1,768°C) ensures reliable operation.

- Corrosion Resistance: Exceptional resistance to acids, alkalis, and other corrosive agents, including aqua regia and oxidizing environments.

- High Thermal Conductivity: Ensures uniform heat distribution for precise laboratory results.

- Mechanical Strength: Resists cracking and deformation under thermal and mechanical stress.

-

- High Purity: Platinum pellets are typically available with purity levels of 99.95% (3N5) or higher, ensuring that the resulting thin films are of the highest quality and free from contamination.

- High Melting Point: With a melting point of 1768°C, platinum is suitable for high-temperature evaporation processes.

- Excellent Corrosion Resistance: Platinum coatings offer superior protection against corrosion and oxidation, making them ideal for use in harsh environments.

- Good Electrical Conductivity: Platinum’s excellent conductivity makes it a popular choice for thin-film electrodes and interconnects in microelectronics and other applications.

- Durability: Platinum coatings are resistant to wear, making them long-lasting and suitable for high-use applications.